The semiconductor industry is a key cornerstone of the modern information society. With the accelerated evolution of new technological changes such as artificial intelligence and the Internet, the development of the electronic information industry has entered a new round of upgrading and transformation. The demand for the semiconductor market is also growing. The global semiconductor industry has bucked the trend and increased by 6.5%. China is the world's largest semiconductor market.

A wafer is a thin slice of semiconductor material used to fabricate integrated circuits or other microdevices1. Also called a slice or substrate, wafers must undergo a number of steps in the preparation process before they are ready for use.

Manufacturing processes for silicon semiconductor

Silicon Ingot ⇒ Cropping(electroplated bandsaw) ⇒ Cylindrical / Flat Grinding Silicon Rod ⇒ Ingot Silicon (diamond wire) ⇒ Lapping (double side wheel/polishing pad) ⇒ Edge Grinding ⇒ Surface grinding ⇒ polishing⇒ wafer⇒ patterning ⇒ back grinding (vitrified / resin wheels) ⇒ dicing (dicing blades)⇒ chips ⇒ molding ⇒ packaging

More Superhard provides diamond tools for the semiconductor industry including

►

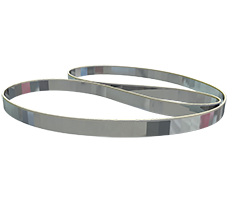

Diamond Bandsaw Blades

Cutting silicon ingot in semiconductor industry. Thery are also cut sapphire ingot , quartz glass, etc

Edge shapes diamond bandsaw blades: continuous, segmented ( half moon) and serrated shape

►

Cylindical / Surface Grinding Wheels

Peripheral grinding of silicon ingots, or processing the outer surface of silicon ingots and to make orientation flat

►

Edge Grinding Wheel

Edge wheel/ chamfering wheels for silicon and sapphire wafer edge grinding. A small diamterer wheel for notch grinding

►

Dicing Blades ( Hub type and Hubless type)

Ultra - thin diamond dicing blade ( hub type and hubless type) for scribing silicon wafers, compound semiconductor wafers (GaAs, Gap)

►

PU Polishing Pad

Polishing and finishing of glass, LCD/LED substrates, precision optics, hard disk, metal and semiconductor wafer surfaces

.jpg)