What is the unit of particle size?

Many people may only know straight by using the length unit millimeter, micron, etc., in fact, professionally the particle size unit is more commonly used to indicate the number of mesh. The mesh size refers to the size of the raw material particles, generally expressed by the maximum length of the particles.

.png)

Mesh is the size of the sieve hole size of the standard sieve. In the Taylor standard sieve, the so-called mesh is the number of holes in a length of 2.54 cm (1 inch) and is referred to as mesh.

The mesh is the number of empty eyes on the screen per square inch, 50 mesh means 50 holes per square inch, 500 mesh is 500, the higher the mesh number, the more holes. In addition to indicating the mesh of the screen. It also indicates the particle size of the particles that can pass through the screen, the higher the mesh number, the smaller the particle size, and the particle size we can use M to express. The size of the powder particles is called particle size.

Particle size and mesh conversion

M inner diameter of sieve (μm) ≈ 14832.4 / mesh of the sieve

The finer the particle, the larger the mesh, similar to the magnification of metallographic tissue. A positive or negative sign in front of the mesh number indicates whether the mesh can be missed. A negative number means that the mesh can be missed, i.e., the particle size is smaller than the mesh size, while a positive number means that the mesh cannot be missed, i.e., the particle size is larger than the mesh size. For example, the particle is -100 mesh ~ +200 mesh, that is, these particles can leak through the mesh hole with 100 mesh and can not leak through the mesh hole from 200 mesh, in screening the particles of this mesh, the mesh of large (200) screen should be placed under the mesh of small (100) screen, in the mesh of large (200) screen left for the particles of -100 ~ +200 mesh.

.png)

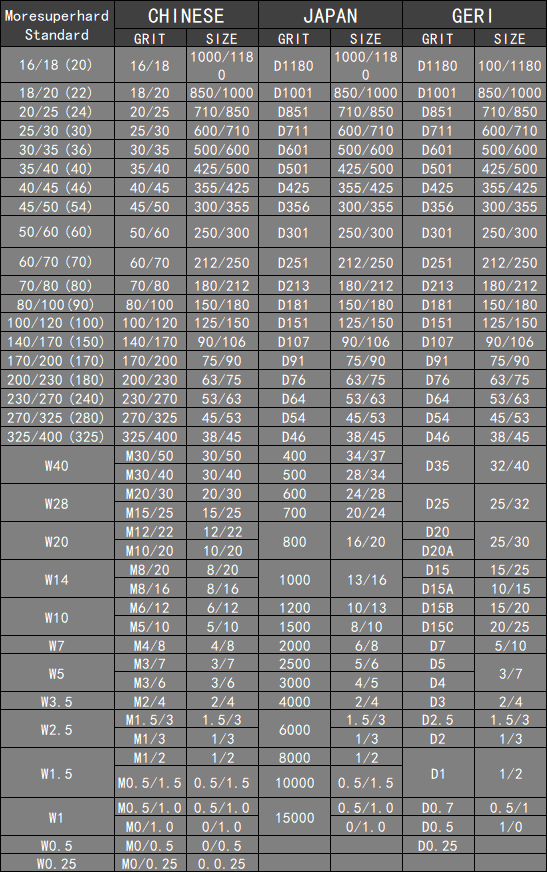

Because of the problem of hole opening rate, that is, because of the difference in the thickness of the wire used in weaving the mesh, the standard varies from country to country.

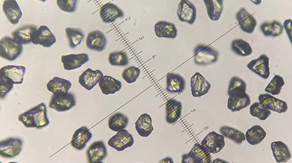

In the process of making and using diamond grinding wheels, we often mention abrasive grit.

Abrasive grit is actually "grit composition" to be precise. Because what we often say about grit size, such as "CBN 80/100, 100/120", is actually a grit number, which refers to a range of grit sizes (grain group), including the coarsest, coarse, basic, fine, and finest grains.

For example, 80/100 is a particle size number with a nominal size range of 150-180 μm, which indicates the superabrasive falling between two layers of sieves with aperture sizes of 180 μm and 150 μm, respectively.

Among them, the abrasive on the upper sieve is the coarsest particle, which is usually called large particle, and needs to be strictly limited, such as the presence of defects that can easily cause the workpiece to "scratch"; the abrasive on the upper inspection sieve is coarse; the abrasive on the lower inspection sieve is basic; the abrasive under the lower inspection sieve is fine; and the abrasive under the lower inspection sieve is the finest particle.

With the increase of international interaction, domestic super hard abrasives products often need to "benchmark" with similar foreign products, but the standards of each country are different, so we must pay attention when selecting the "particle size number".

In order to better grasp the specific grain size comparison and other related content, we summarized a good grain size comparison table, grain size finish comparison table, roughness conversion table, quickly collect!

.png)

.png)