Hydraulic industrial equipment is so commonly used that it’s easy for us to overlook it. In fact, we see and experience the benefits of hydraulic equipment every day. The dependability of these systems make them a great tool for a number of different industries that affect our everyday lives.

A hydraulic press is a machine tool that uses liquid pressure to transmit energy to achieve various pressure processing techniques. With the application of new processes and new technologies, hydraulic presses are more and more widely used in metal processing and non-metal forming, and their share in the machine tool industry is rising significantly.

Hydraulic presses are suitable for most processes that require pressure machining.

At present, hydraulic presses are mainly used in the following fields:

1. Stamping and drawing process of sheet metal parts

Mainly used in the forming and processing of metal coverings in the automobile and home appliance industries;

2. Pressure forming of metal mechanical parts

Mainly include die pressing, extrusion forming of metal profiles, hot and cold die forging, free forging and other processing technologies;

3. Powder products industry

Such as magnetic materials, powder metallurgy, etc.;

4. Press forming of non-metallic materials

Such as SMC molding, hot pressing molding of automotive interior parts, rubber products, etc.;

5. Hot pressing of wood products

Such as hot pressing of plant fiber sheets and profiles;

6. Other applications: such as pressing, calibration, plastic sealing, embossing and other processes.

Grinding Solutions for Hydraulic Components:

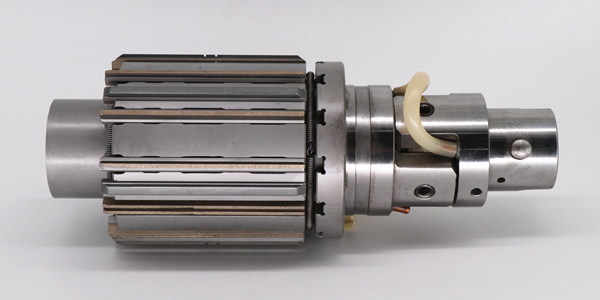

1. Hydraulic gear pump pinions

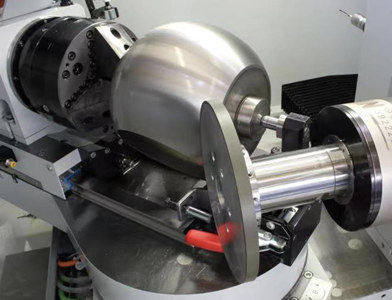

2. large hydraulic trunnions

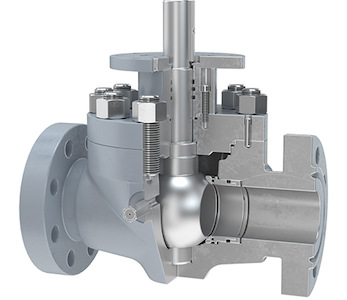

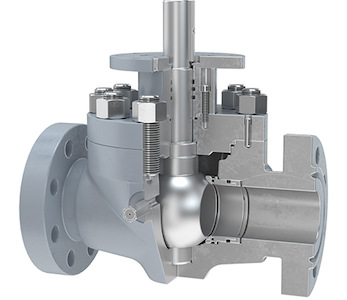

3. Floating ball valves

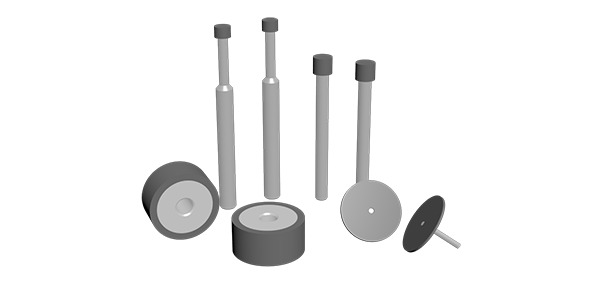

Moresuperhard's Internal Grinding Solutions

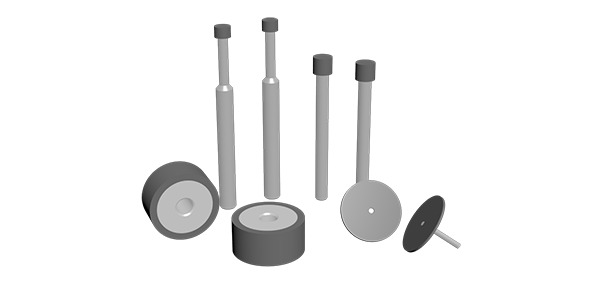

Resin Diamond & CBN Grinding Heads/Pins/ Mounted Points for Internal Grinding

Electroplated Diamond Nounted Points

Moresuperhard's Internal Grinding Solutions

Resin Diamond & CBN Grinding Heads/Pins/ Mounted Points for Internal Grinding

Electroplated Diamond Nounted Points

Resin or electroplated bond diamond mounted points are excellent tools for grinding small areas with diamond smoothing tools for making a clear polished surface finish. This tool has a unique quality that is recommendable for stone carving, cleaning up work, glass, ceramic, and metal.

Moresuperhard's Honing Solutions

Grinding with Metal/Vitrified Bond Diamond Honing Stone

More Superhard provide diamond and CBN honing stone for honing machines of almost all renowned honing brands (Sunnen, Nagel, Belden, AccuCut, Engis, and other types of high-production honing equipment ). Our diamond and CBN honing stones are available for precisiom bore finishing.

.png)

.png)

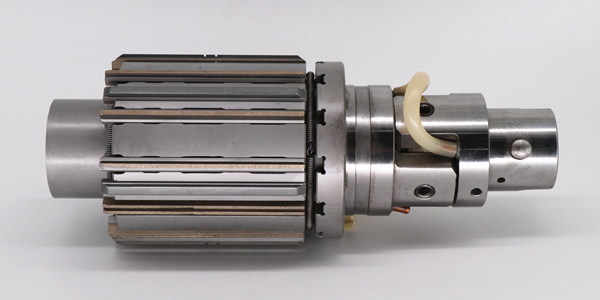

4. Hydraulic gear pump gear shaft

hydraulic gear pump hydraulic gear pump shaft

5. Hydraulic control valve - lift valve

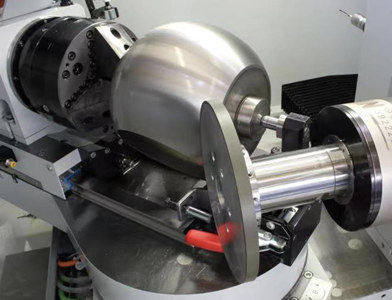

Moresuperhard's Exernal Cylindrical Grinding Solutions

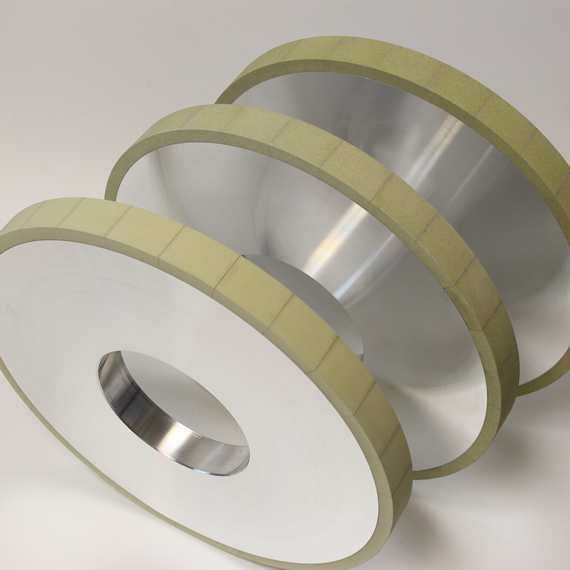

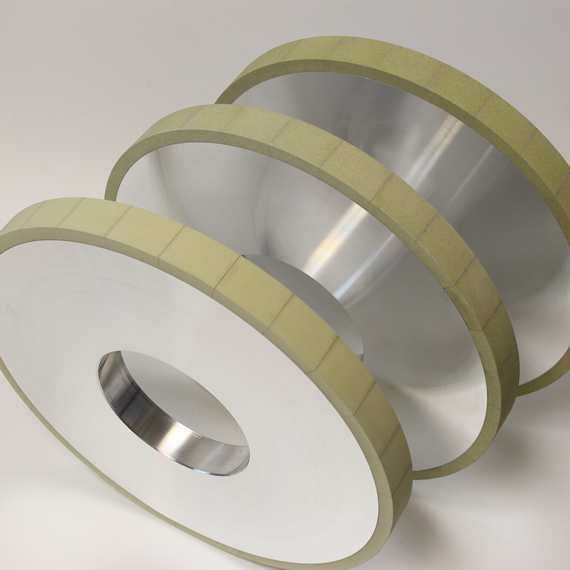

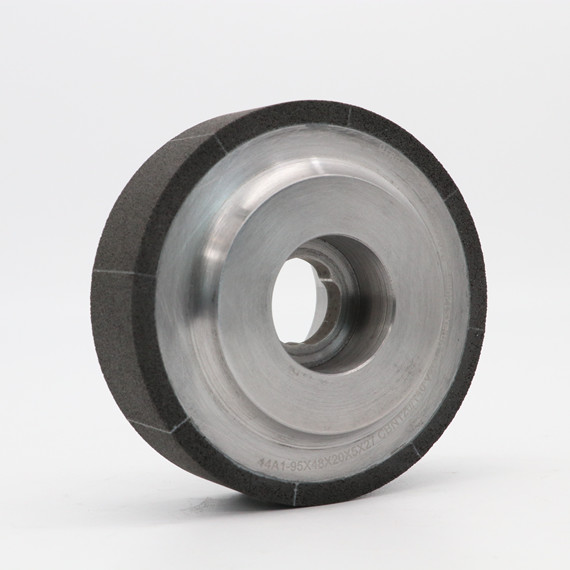

Precision Vitrified Grinding - Cylindrical CBN/Diamond Wheels

Moresuperhard's Exernal Cylindrical Grinding Solutions

Precision Vitrified Grinding - Cylindrical CBN/Diamond Wheels

Cylindrical diamond wheels are widely used in grinding various ceramics such as aluminum oxide ceramics, zerconia ceramic, silicon carbide ceramics in engineering applications.

We can produce conventional cylindrical wheels and superabrasive diamond & cbn cylindrical wheels. Most applications, predominantly use aluminium oxide grinding wheels in a vitrified bond with particle sizes ranging between 54 and 180, and hardness grades between H and L (depending on requirements).

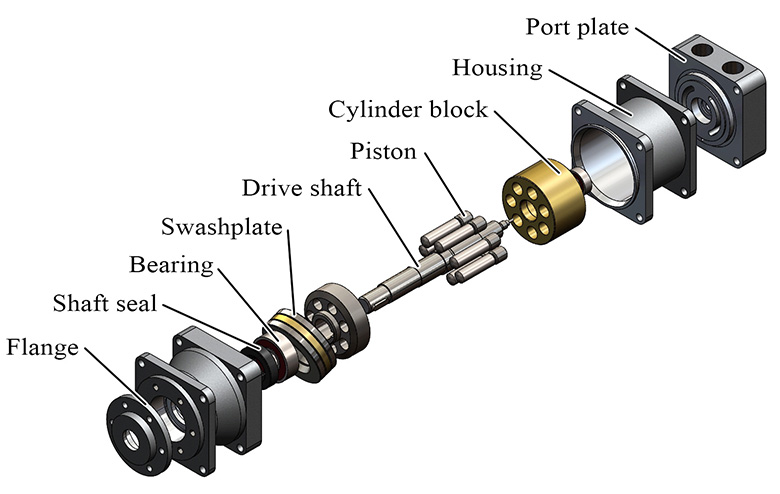

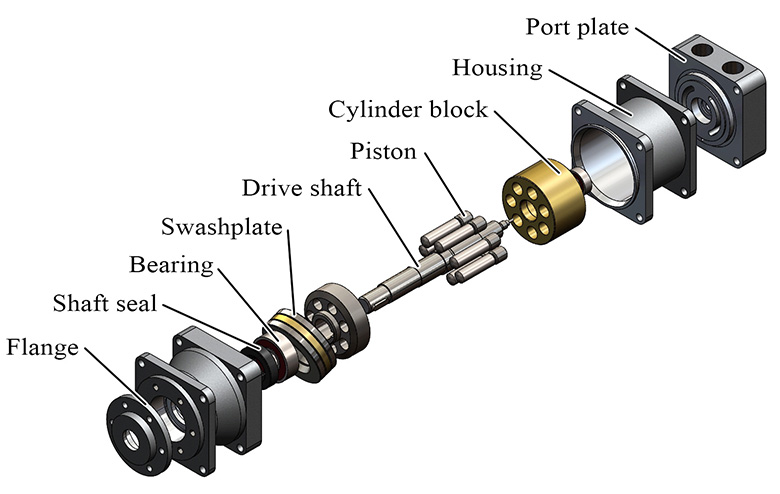

Hydraulic Piston Pump Components:

6. Hydraulic piston pump piston

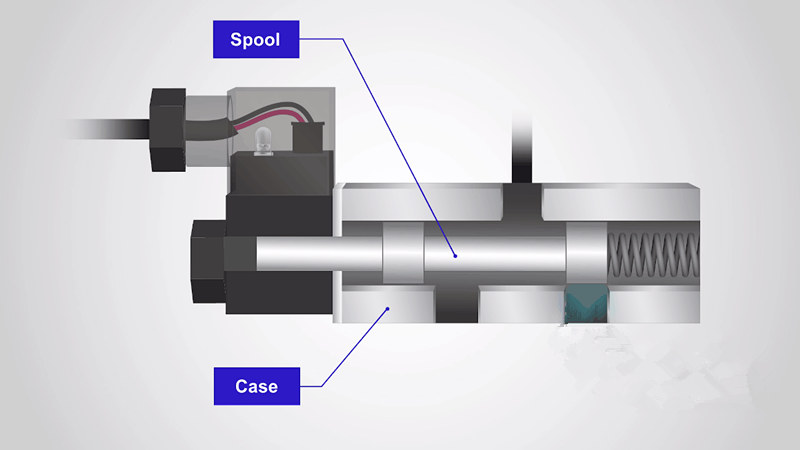

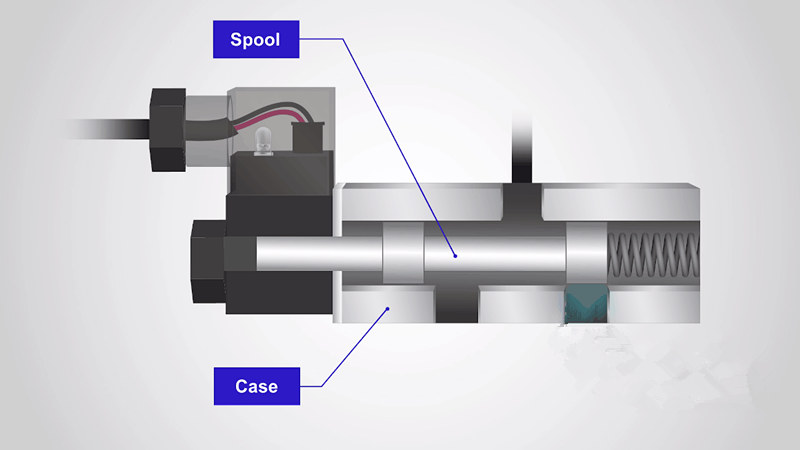

7. Hydraulic control spool valve

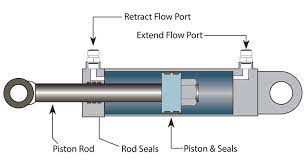

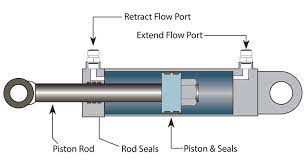

8. Connecting rod for hydraulic cylinder

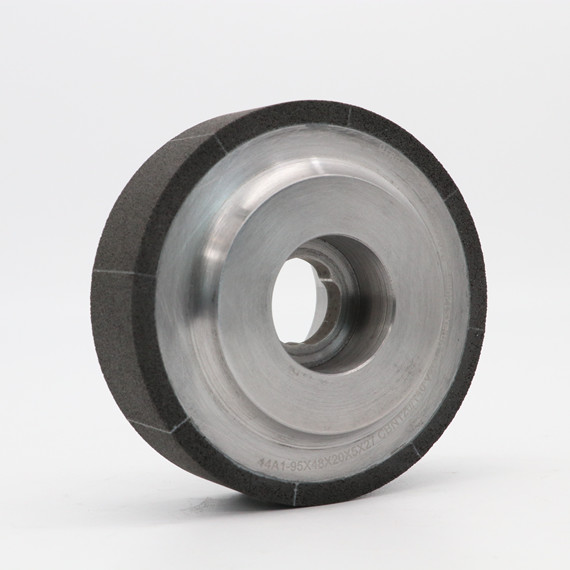

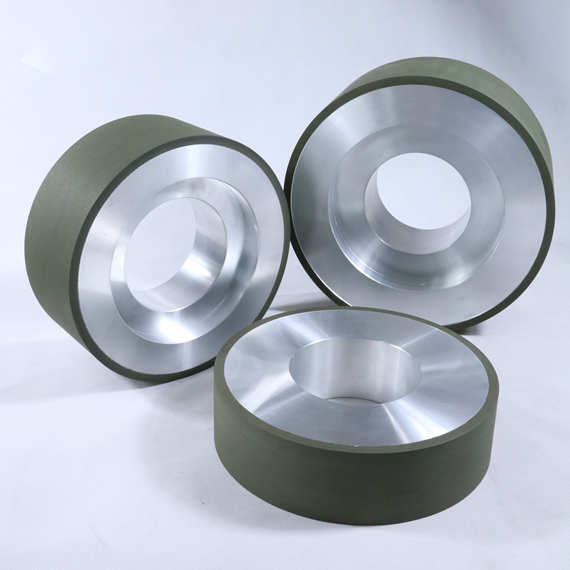

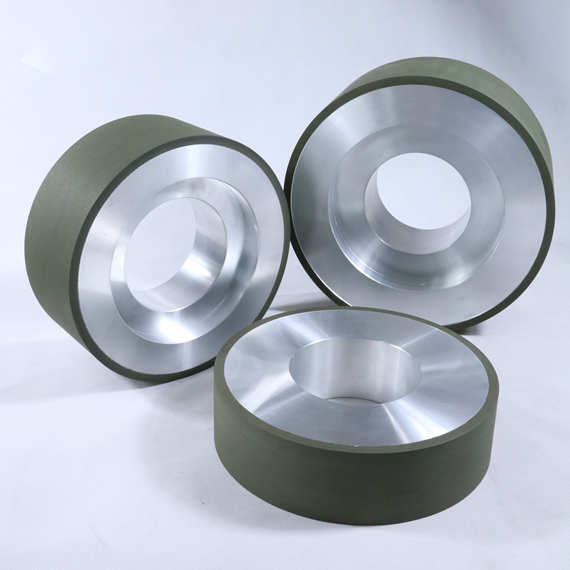

Moresuperhard's Centerless grinding Solutions

Centerless Resin Bond Diamond Grinding Wheel

Moresuperhard's Centerless grinding Solutions

Centerless Resin Bond Diamond Grinding Wheel

Centerless grinding processes the outer periphery of a cylindrical workpiece using a centerless grinding machine. A workpiece is supported between a fixed blade and a rotating adjusting wheel and a grinding wheel. The rotation and feed of the workpiece are then adjusted by rotation of the adjusting wheel to grind the outer circumference of the workpiece. Centerless grinding requires neither a center hole in the workpiece nor the workpiece’s installation on and removal from the grinding machine.

Applications: Rough, semi-finish and finish grinding tungsten carbide, ceramics, magnetic material, stainless steel bar, PCD and PCBN compositives

.jpg)

.png)

.png)