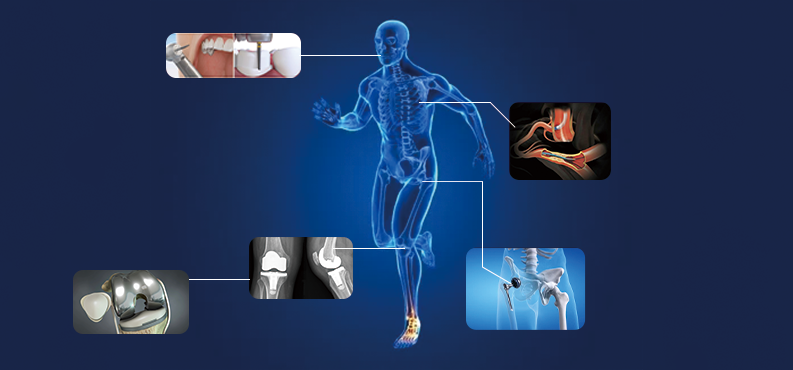

We have been successful in the medical technology market for many years, especially hip and knee joints, trauma implants, surgical instruments and other devices or hypodermic needles used to process medical devices.

What types of medical tools need grinding?

First, let's take a look at the common types of medical operations and the materials they use.

| Classification |

Types |

Body Parts |

Materials |

Orthopedic input |

joint replacement surgery |

hip

lap

shoulder

Elbow

Articulatio coxae |

Processing material:

- Pure titanium and titanium alloys

- Cobalt based alloys

- High nitrogen stainless steel

- UHMWPE

- Peek and reinforced carbon fiber

- ceramics

- Memory alloy |

trauma and spine |

bone platebone peg |

| dentistry |

dental implant |

Surgical Instruments |

Tweezers and pliers |

| surgical scissors |

| scalpel |

We offer grinding wheels specially formulated for grinding stainless steel, steel, Nitinol and cobalt-chromium alloys, so our grinding solutions can help you remove burrs from medical instruments ranging from syringes and dental equipment to cutting and hollow tools used in surgery.

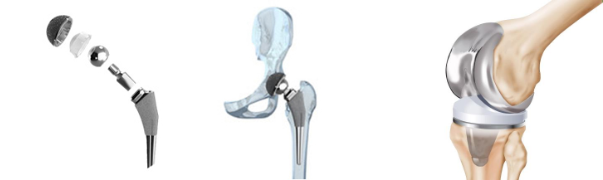

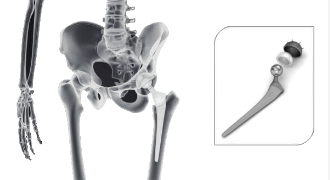

For prosthetic manufacturers, our grinding and polishing systems are widely used in orthopedics such as metal knee joints, ceramic and metal hip joints, and trauma implants.

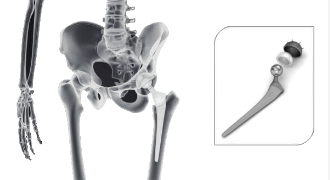

Orthopedic Implants

Orthopedic implants are used to replace damaged or dysfunctional joints in the human body to relieve symptoms and improve function. Artificial joint heads, including hip joints, knee joints, shoulder joints, etc., are a substitute for joint damage caused by arthritis and other reasons. It is a man-made model mainly composed of special metals such as titanium, cobalt and chromium alloys, and special materials such as ceramics and polymer polyethylene. Grinding provides a comprehensive range of products and services for all aspects of hip and knee replacement grinding.

For Artificial Hip Joint and Knee Joint Grinding

What materials are generally used for artificial hip and knee joints grinding and what are their characteristics?

- High-purity ceramics have stable chemical properties, good biocompatibility, biological inertness, high hardness, good wear resistance, and a lower wear rate than other materials. Ceramic material with high strength and durability is one of the ideal artificial joint materials.

- High-purity metal titanium has low density, high strength, easy processing and good corrosion resistance. Titanium alloy has better compatibility with human tissue, and is closer to the elastic modulus of human bone tissue. Titanium dioxide oxide film can be formed on the surface, which is corrosion-resistant and has low density. It can be reliably combined with human bone tissue and is considered to be the most promising. One of the bone and joint prosthesis materials.

1. Grinding in Hip and Knee Joints:

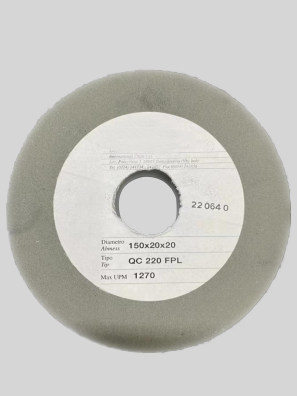

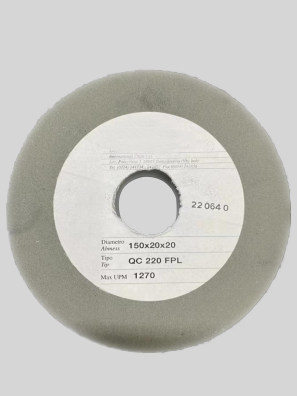

Conventional vitirfied grinding wheels made by pouring method are widely used for polishing bone handles and hip joints in the medical industry. Pouring method is a kind of forming process, natural settlement and sintering. It can be used in grinding femoral stem.

_.jpg) Vitrified CBN Wheels Used for Hip or Knee Joint Grinding

Vitrified CBN Wheels Used for Hip or Knee Joint Grinding

.jpg) Moresuperhard's

Moresuperhard's vitrified CBN grinding tools with the highest grinding layer for extended wheel life on the machine. Due to the special manufacturing process very high grinding layers on wheels are possible to shorten the setup-costs in the grinding process.

Features of vitrified CBN Grinding Wheels:

► longer wheel life

► shorter grinding cycle times

► automated grinding production capabilities with wheels dressed right on the grinder

Vitrified CBN products are ideal for steel and ferrous alloy grinding applications in automotive, aerospace, medical, production tooling, etc. They are excellent thermal conductors and do not react with ferrous materials during the grinding process like diamond does.

.jpg)

We regularly customize Vitrified Diamond products for grinding ceramic and carbide materials used in industries such as glass, ceramics, computer chip manufacturing, thermal spray coatings, and more. Diamond is the hardest known material with the best thermal conductivity making it the best abrasive where there is no chemical reaction.

Matching grinder of vitrified CBN grinding wheels for knee and hip joints grinding:

Schütte、Haas、Hermle、Makino

Other grinding products in knee and hip joints grinding:

Electroplated diamond grinding wheels for hip joint broach:

► Body Type: steel core cbn wheel, aluminum core cbn wheel and plastic cbn wheel

► Diameter: 6 inch, 8 inch and 10 inch

► Thickness :1 inch, 1.5 inch and 2 inch

► Arbor hole :1/2 inch, 5/8 inch, 1-1/4 inch

► Radius edge: 1/4 inch

► Grain Size: 80#, 180#, 220#, 350#, 600#, 800#, 1200# etc.

Applicable grinder: sharpening woodturning tools (high speed steel HSS) on bench grinder

► Advantages: * Fast and cool cutting action without coolant

* No need dressing or turning

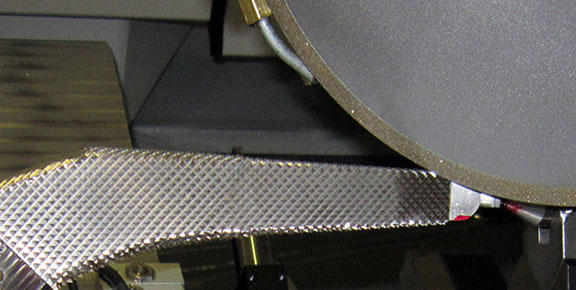

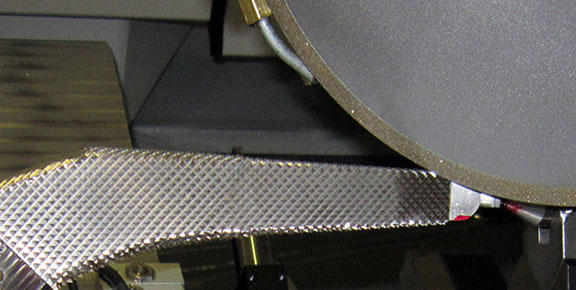

2. Diamond & CBN Sanding Belts for medical devices polishing

.jpg)

Diamond or CBN sand belt is widely used in polishing and grinding process, which can be used to polish artificial joints and medical instruments and other products to achieve cost reduction and efficiency increase. The flexible backbase of the sand belt can provide a consistent, predictable surface effect. Use with hard metal, nickel base alloy, titanium alloy and other polishing.

For surgical instruments Grinding

Moresuperhard

Moresuperhard provides rough grinding, semi-fine grinding and polishing services for surgical instrument workpiece. We have a variety of high-performance grinding wheels for grinding and polishing scalpel blades.

These grinding wheels ensure the highest surface quality during finishing to make clean cuts and minimize scarring after surgery. The services involved are the grinding of forceps, scissors and scalpels, as well as the grinding of bone files for medical reamer drills.

For Dental Instruments Grinding

For Dental Instruments Grinding

Moresuperhard's dental diamond turning needles are used for precision drilling and polishing of ceramic components. Dental diamond wheels are used in dental procedures, such as caries and crowns, preparation of hard tooth tissue, removal of old fillings and treatment and polishing of fillings.

For Syringe Needles Grinding

For Syringe Needles Grinding

Grinding and Pointing of Hypodermic Needles, Blood Lancets, Infusion Sets, Dental Needles etc.

Grinding The Needle With Diamond Grinding Wheel Can be Divided Into The Following 3 Steps:

Grinding The Needle With Diamond Grinding Wheel Can be Divided Into The Following 3 Steps:

1. Rough grinding (30#-120#). Use a coarse-grained diamond /CBN grinding wheel to grind the round rod into a needle shape.

2. Universal grinding (150#-250#). Then grind the stainless steel bar to determine the rough shape of the tattoo needle and make the tip smooth.

3. Finish grinding 320#-600#(W28). Lower the feed speed and grind it slowly, get a nice smooth surface.

For Medical Customized Wire Grinding

Medical Customized Wire is usually Customized by centerless grinding, and typical types of ground cables include core Wire, mandrel, and guide Wire. The centerless grinding taper allows for optimal stiffness and flexibility of the surgical line over the entire length of the medical device. Grinding long taper, short taper and step to meet your medical equipment needs. Moresuperhard can create taper at any Angle and maintain very tight tolerances throughout the contour.

Centerless Diamond Grinding Wheel for Medical Customized Wire Grinding Centreless (centerless) grinding can perform excellent roundness of the work piece.The workpiece is supported by a work rest blade and set between a rubber regulating wheel that rotates the workpiece and a rotating grinding wheel.

Details of Centreless Grinding wheels:

Details of Centreless Grinding wheels:

► Application: grinding carbide, ceramic, magnetic materials, stainless steel bar, PCD & PCBN compositives

► Model: 1A1 , 6A1, 9A1

► Bonded Type: Resin bond, Metal bond

► Centerless Grinder Machine: Koyo, Crystec, Dedtru, Landis , Okuma, Paragon, Royal Master, Unison, WMV

_.jpg)

.jpg)

.jpg)

.jpg)