Automated polishing applications include polishing, grinding, trimming, cutting, and deburring. Moresuperhard can provide customized polishing solutions to meet your specific applications.

What is a workpiece-type polishing robot ?

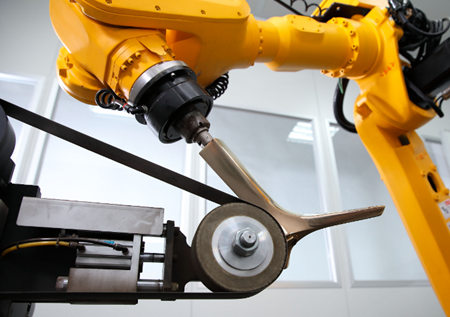

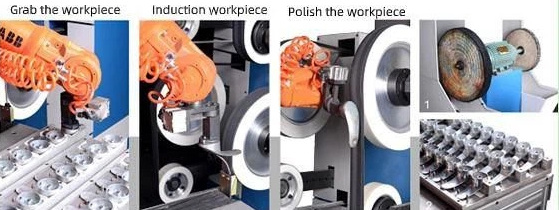

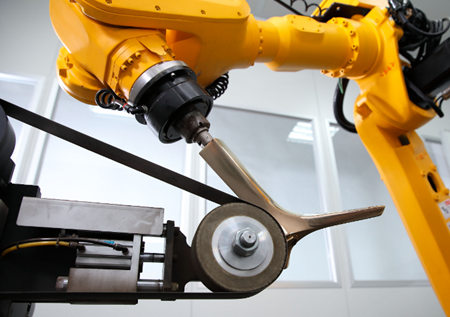

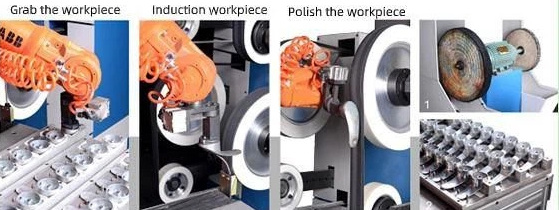

A Workpiece-type polishing robot is an automated polishing robot system that uses a robotic gripper to grip the workpiece and deliver it to various fixed positions on a polishing machine, completing different processes and processes such as grinding and polishing. The sand belt polishing robot is the most typical among them.

A polishing robot that achieves automation through programming or teaching methods, while also possessing humanoid form and functions as a mechanical device. Engaged in surface polishing, edge deburring, weld seam polishing, internal hole deburring, chamfering of hole threads, surface wire drawing, grinding and polishing, and other work. Its work efficiency is more than ten times that of manual labor.

Therefore, polishing robots are widely used in the field of industrial manufacturing, with many parts requiring post-processing after welding, casting, forming, or processing. For example, in the automotive industry, the engine cylinder block, cylinder head, gearbox housing, and wheel hub are deburred, polished, and polished by industrial robots, and the surface is shiny and transparent, ensuring the high efficiency of assembly and synthesis of various components and the high level of overall vehicle delivery; In the aviation and energy industries, engine blades can be automatically polished by polishing robots following the trajectory of blade surface changes. This ensures uniformity of polishing without damaging the blades, achieving a smooth and clean surface after polishing without the need for manual processing. The perfect tactile appearance of laptops, tablets, and mobile phones in the 3C industry also embodies the professional labor achievements of polishing robots.

Robot Polishing Case:

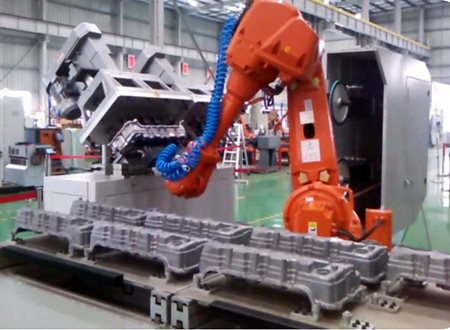

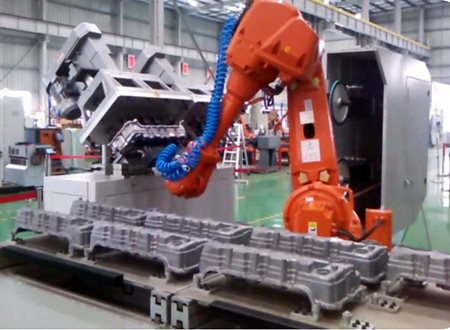

Grinding and deburring of casting cylinder heads:

The core component of robot polishing and deburring is the high-speed electric spindle. Due to the uncontrollable shape of the blank, floating polishing is usually used to adapt to the shape of the blank, using flexibility to overcome rigidity and slowly grinding off excess materials.

According to the needs of the polishing process, design grinding equipment such as sanding belt machine, brush machine, polishing wheel, etc. to fully meet the rough and fine processing of polishing, polishing, and deburring. Fully meeting the automation processing needs of the polishing robot unit, the optimal coordination between the robot and peripheral equipment such as polishing machines is achieved through the overall system control, achieving the expected polishing processing effect.

The casting cylinder head polishing and deburring workstation uses a workpiece type polishing robot, and adopts a combination of multi-axis machine, sand belt machine, and floating spindle to remove burrs such as holes, edges, lines, and surfaces of parts caused by pressure impact and insufficient locking force, and to improve production efficiency, reduce costs, and improve product yield.

Moresuperhard's Solutions for Grinding and Deburring of Casting Cylinder Heads:

Diamond & CBN Sanding Belts:

► Bond: Metal nickel plating electroplated bond & Resin bond (resin bond also consists of flexible and hard type)

► Length: 150mm - 5000mm

► Width: 5mm - 350mm

► Grit: #60,#100,#120,#200,#400,#800,#1500,#2000,#3000,#5000

.jpg)

.jpg) Applications of Diamond and CBN Sanding Belts:

Applications of Diamond and CBN Sanding Belts:

Diamond & CBN sanding abrasive belt can be widely used for grinding steel, stone, glass, ceramics, monocrystalline silicon, polysilicon, zirconia, alumina, metal-nonmetallic synthetic materials, cemented carbide, aluminum-magnesium alloy, aluminum beryllium alloy, titanium alloy and etc. hard brittle materials.

.jpg)

.jpg)