.jpg)

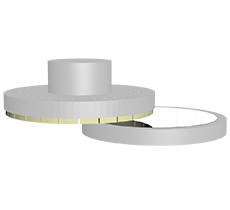

Metal bond blades are using sintered metal powder as the bonding agent, have the excellent ability to hold its shape for a longer period of time, high rigidity minimized wavy and slant cutting.

The blades have strong control ability and high wear resistance, it is suitable for precison cutting and slotting machining of electronic components and optical components.

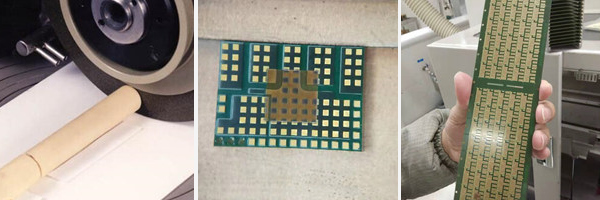

Applications of metal diamond dicing blade

Scribing electronic parts, optical devices, semiconductor packages, BGA, CSP, PCB, ceramic, glass, quartz, crystal, ferrite, optical communication (Faraday), etc

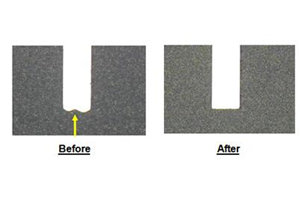

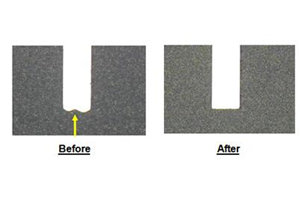

Dresser Board for dressing dicing blades

Dresser board is used for dressing and edged blade row, to increase sharpness, and reduce the chipping of the work piece, to reshape and perfect the blade edge to a flat edge

How to selection of the correct types of dicing blades to cut materials

* Binder of resin bond (soft strength) dicing blade, scribing hard and brittle material

* Binder of metal bond (medium strength) dicing blade

* Binder of electroplated bond (hard bond), scribing softer material

.jpg)

.jpg)