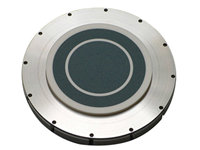

Application of porous ceramic chuck tables

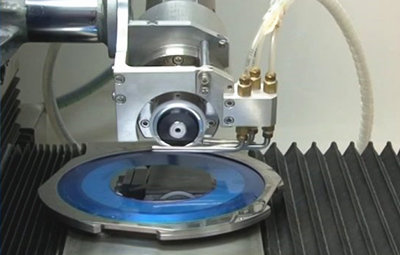

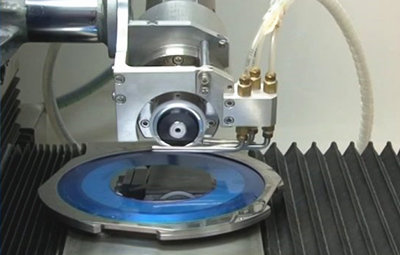

porous Ceramic Chuck Tables are widely used as important components of equipment in silicon wafer, semiconductor compound wafer, piezoelectric ceramic, glass, LED, semiconductor package component substrate, optical component thinning, cutting

It is suitable devices: Disco, ADT, K&S, TSK, OKAMOTO dicing saws and wafer grinder, thinning, clearance, transportation machine, etc

Classification of chucks by applications

Classification of chucks by applications

► Thinning chucks

► Dicing chucks

► Cleaning chucks

► Transportation chucks

► Grinding chucks

The benefits of porous ceramic chuck table

The benefits of porous ceramic chuck table

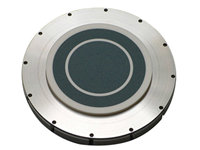

• Due to the pores that are very tiny and averagely spread, vacuum chuck would not cause harms and scratch on your work pieces, improving the yield rate, making the best partner of manufacture.

• High precision of surface flatness of 5 micron

• Custom chucks for dicing saws, wafer mounters and wafer washers.

• Object suction, easy dress

• High strength: No deformation during grinding, to ensure that the silicon wafer is uniformly stressed at all points during grinding, and is not easy to edge breakage and debris.

.jpg)

.jpg)