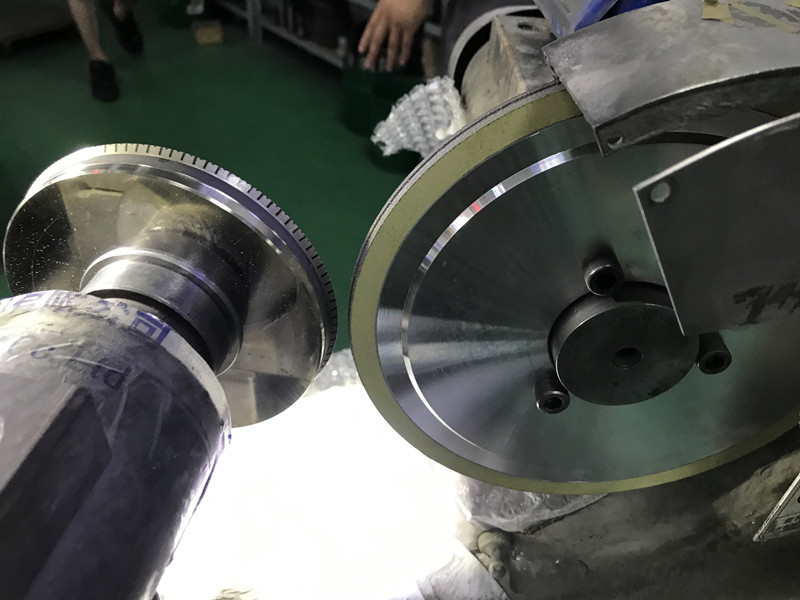

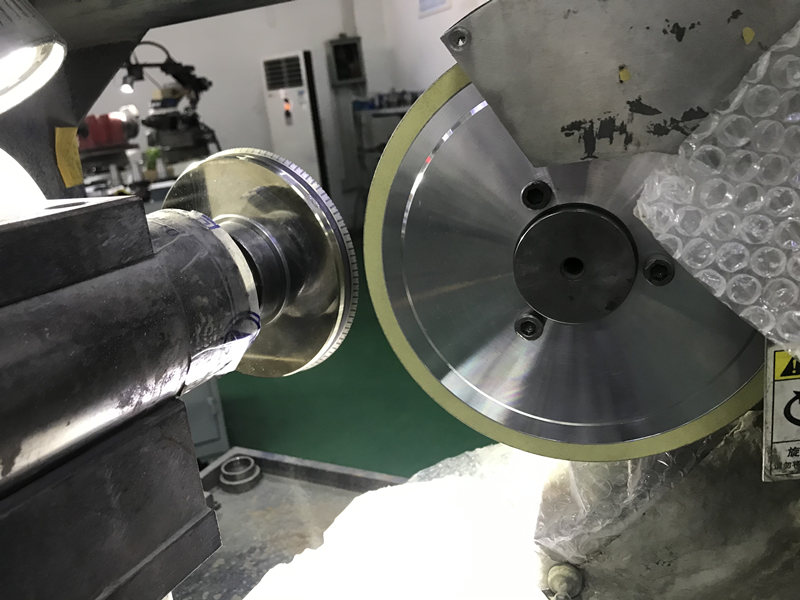

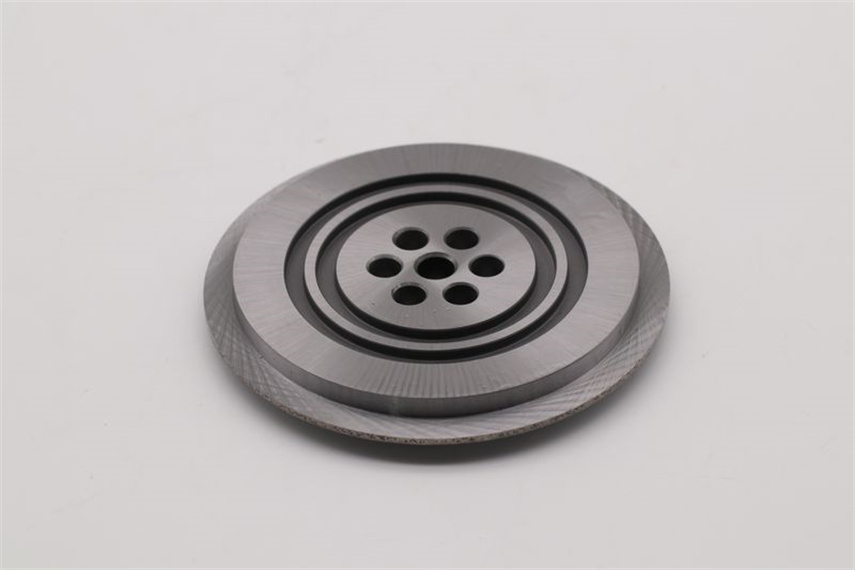

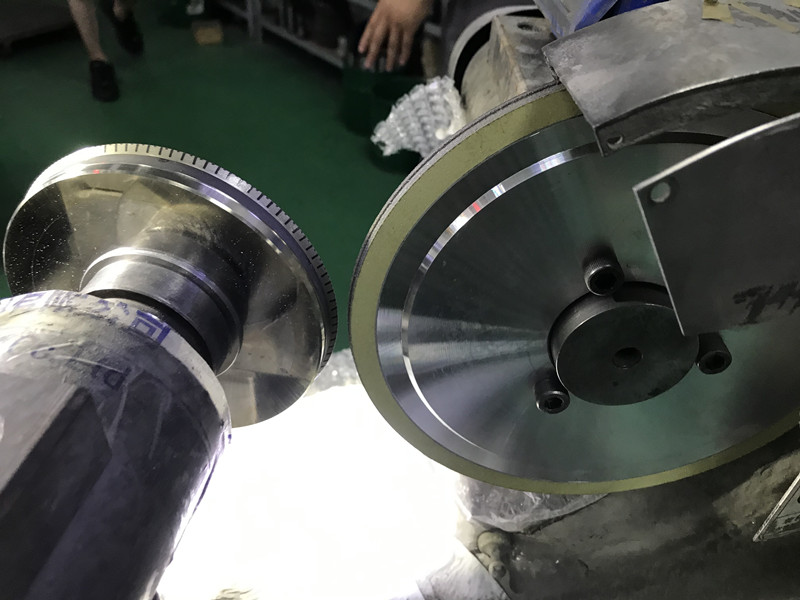

Form diamond roller for camshaft grinding

The form diamond roller is used for dressing grinding wheels ( vitrified cbn grinding wheel, conventional grinding wheel).

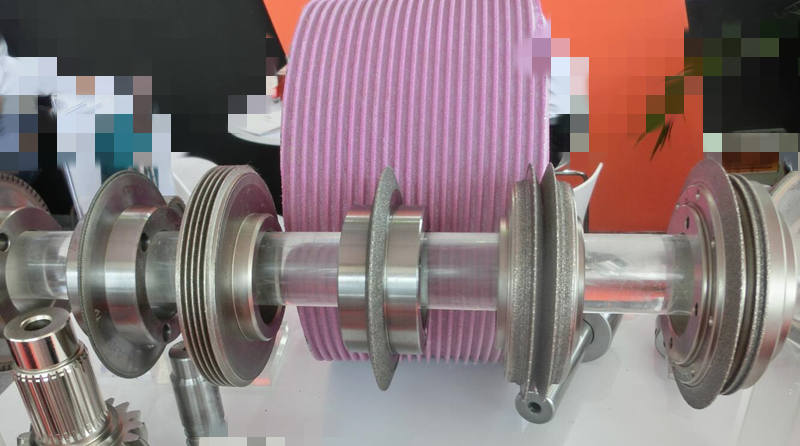

Used for Automobile engine, machinery industry, robot parts, flute dresser, turbine blade, automobile valves, crankshafts, sewing industry, turbine blade – fir tree root form, cam Grinding, bearing industry, ball joints, needle injectors

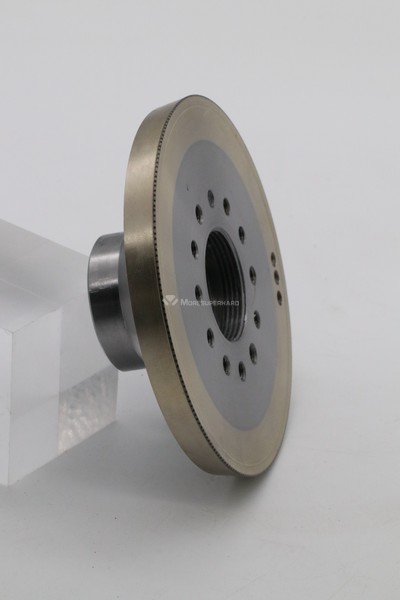

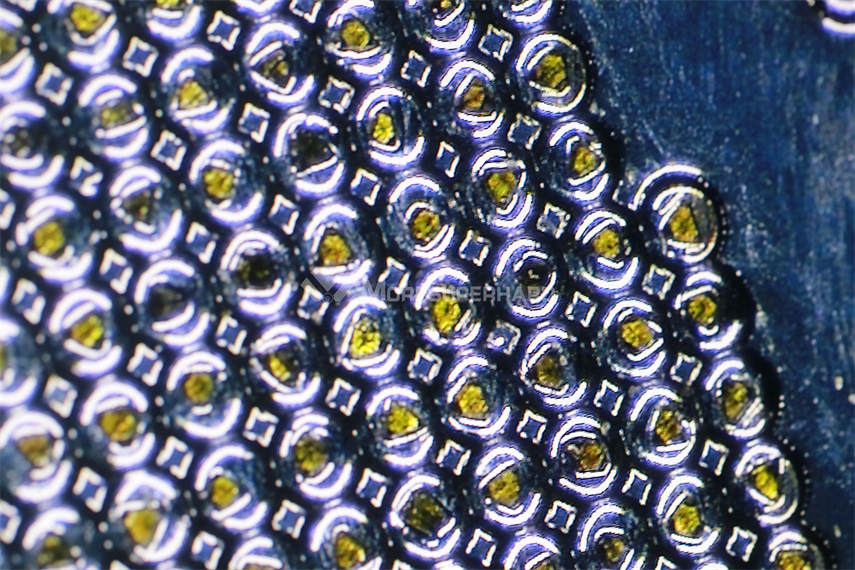

High precision form diamond roller for the desired grinding application. Also available are CNC dressing wheels with PCD or natural diamonds and gear grinding wheels or custom-built diamond tools for grinding of CBN wheels.

Rotary form diamond roller and Form Rolls moresuperhard offers High Precision Rotary Diamond dressers and Form Rolls to shape grinding wheels at shortest possible time. These dressers are offered profiling the simplest work piece to the most complicated shape with required precision demands.

When choosing form diamond roller , consider the following factors.

1 Machined workpiece

Mainly includes workpiece name, material, heat treatment state, technical requirements, machining allowance (radial, axial, etc.), and machining accuracy

2 Machine tool

To learn about the machine tool manufacturer, machine model, machine type(external cylindrical grinding, surface grinding, crankshaft grinding, bearing grinding, etc.), especially to learn about the application objects of machine tool, processing methods and machining accuracy.

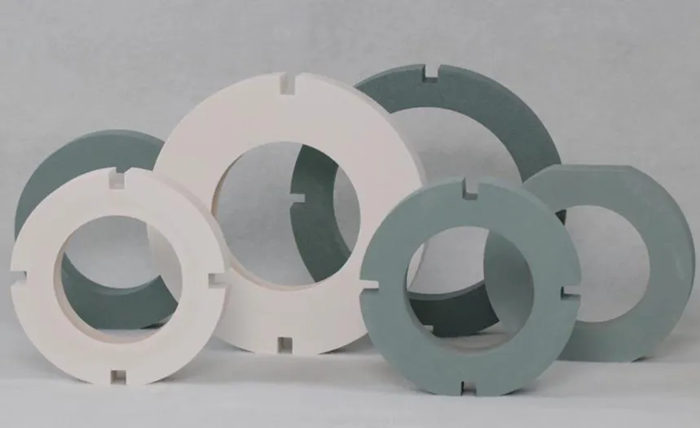

3 Grinding wheel

Select the size( outer diameter, thickness, bore diameter) of the grinding wheel and other technical parameters( abrasive, grain size, hardness, bond, linear velocity, etc.)

4 Driving equipment

If the machine tool has the driving equipment, pay attention to the size of the diamond rotary dresser ( max diameter, width, bore diameter). If there is no driving equipment for the machine tool, taking into account the dressing clamp, processing method and the size of the diamond rotary dresser.

5 Grinding parameters

It includes the linear velocity of grinding wheel, RPM of the workpiece, feed amount, feed speed, dressing cycle, grinding coolant, and etc.

6 Dressing position

It should be reasonably selected according to the actual situation.