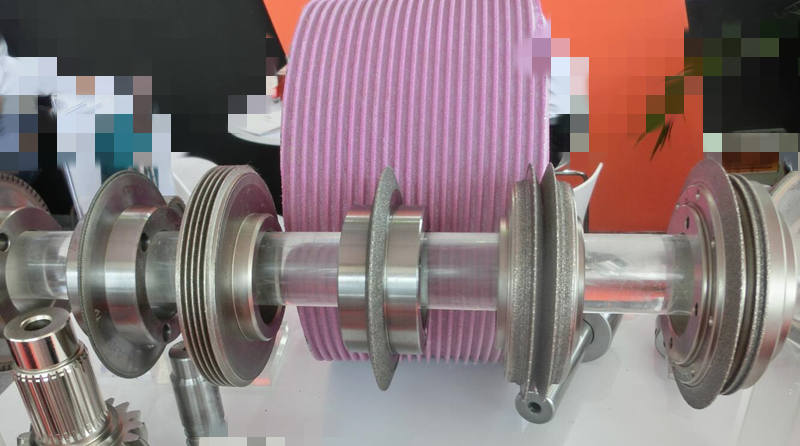

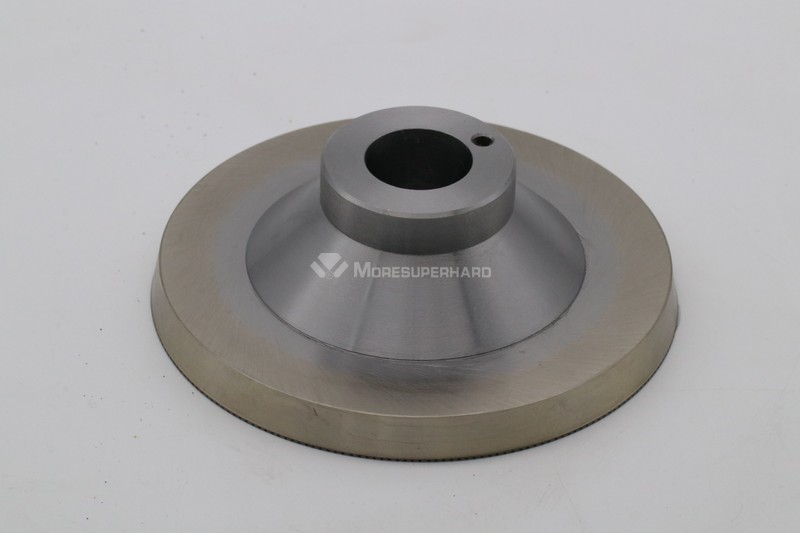

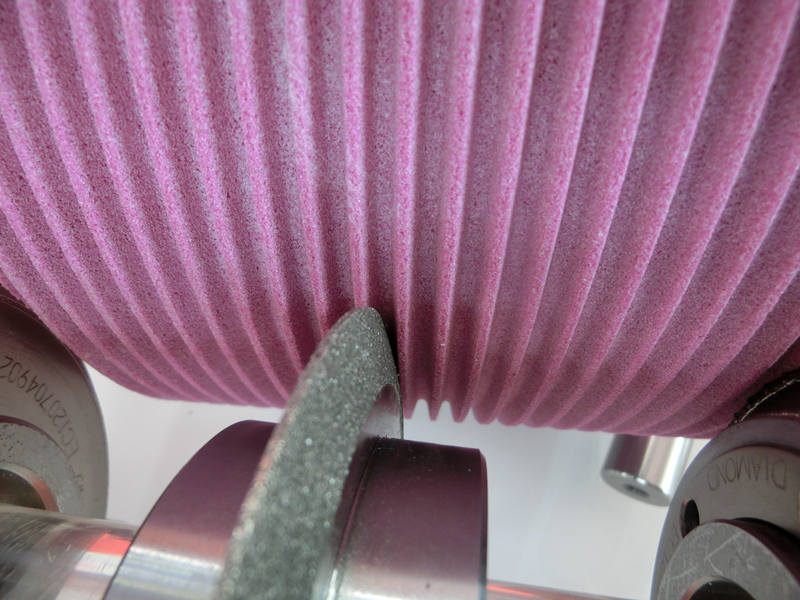

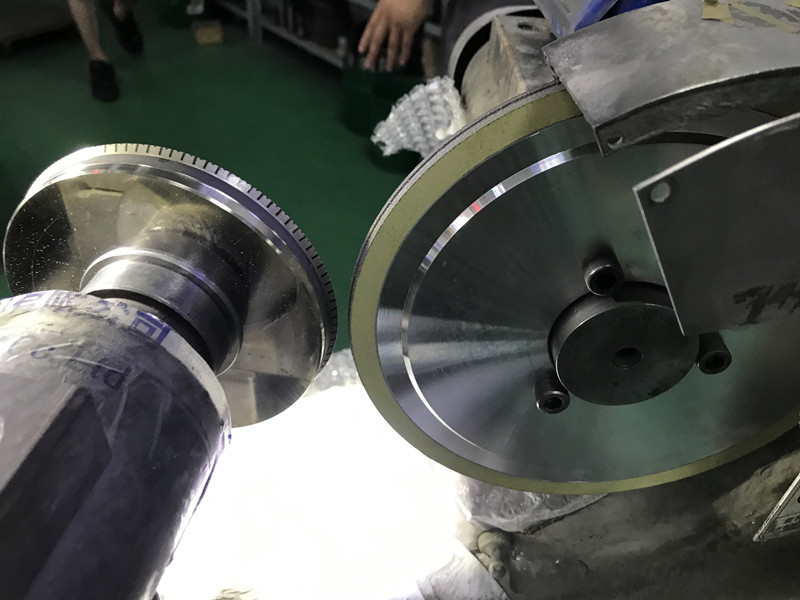

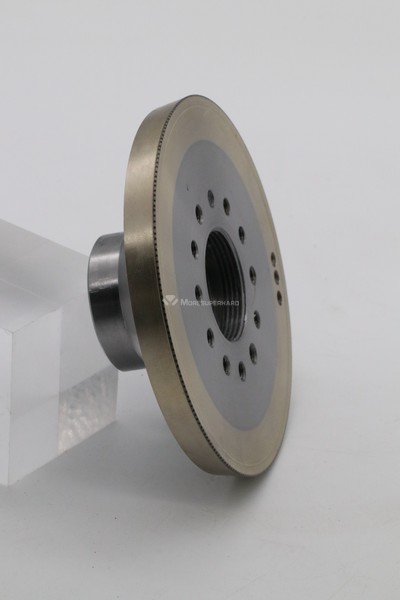

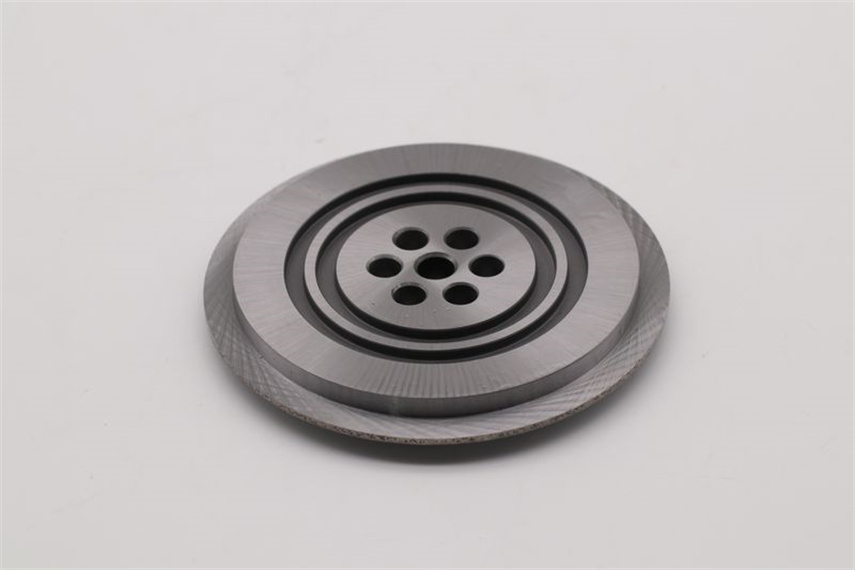

World top electroplated diamond dressing roller

Manufacturing precision requirements for electroplated diamond dressing roller

Runout: 0.002mm

Straightness: 0.002-0.005mm

Roundness: 0.002-0.005mm

Tolerance range of length and step difference: L±0.002-0.005mm

Radius dimension tolerance range: R±0.002-0.005ram

Angle tolerance range: A±1

Note editing Voice of electroplated diamond dressing rolls

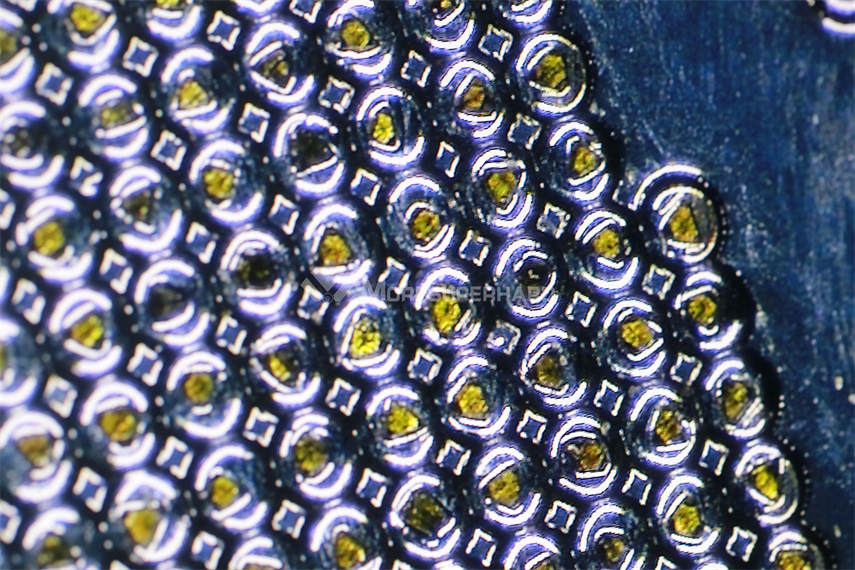

(1) The particle size of diamond should be one size coarser than that of the grinding wheel to be dressed, and the diamond particle size should be close to the same, and the particle shape should be approximately spherical. The commonly used particle size is 36 # ~100 #.

(2) Generally, the direction of the linear velocity at the contact point of the roller and the grinding wheel is in the same direction, and the ratio of the linear velocity of the roller to the linear velocity of the grinding wheel (qd value) is taken as +0.3~+0.7, which is better, and should not exceed +1; when dressing The cutting amount of the roller should be 0.5~1 μm per revolution of the grinding wheel, and the total amount of the grinding wheel should be 0.02~0.04 mm each time; the light repair time should be compressed as much as possible.

(3) The manufacturing error of the diamond roller should be less than 1/2 of the workpiece tolerance, and the clearance between the roller hole and the mounting bearing should be 2 to 4 μm.

(4) Natural or synthetic diamonds can be used, and synthetic diamonds must be high-strength diamonds, such as diamond SCD for grinding steel or high-strength diamond SMD.

(5) When manufacturing rollers, rollers with general precision can be manufactured by external plating and sintering methods, and rollers with high precision and complex profiles can be manufactured by internal plating, and they can be ground and trimmed at the same time.

(6) When the diamond roller is dressing the grinding wheel, it must follow the action program of fast forward (cannot touch the grinding wheel) → slow forward (feed according to the required cutting speed) → light repair → exit, and no step is allowed, otherwise the life of the roller cannot be guaranteed.