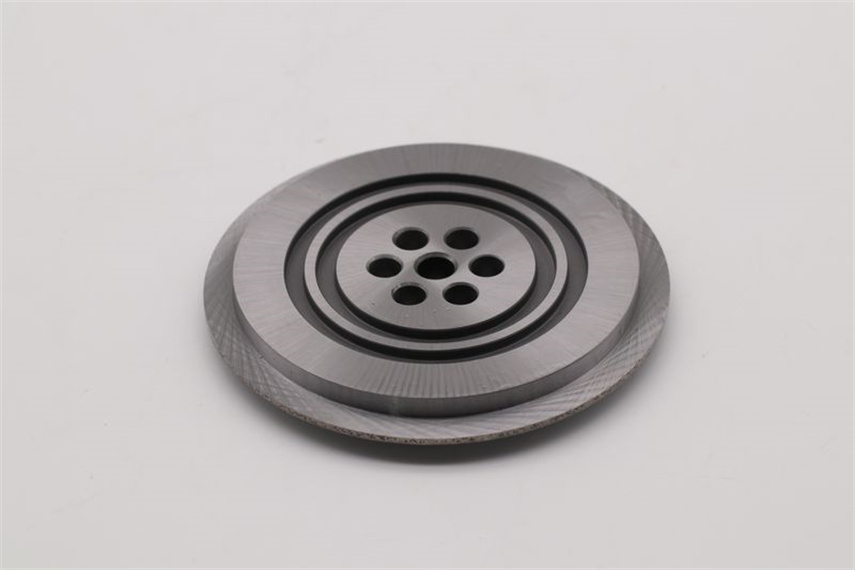

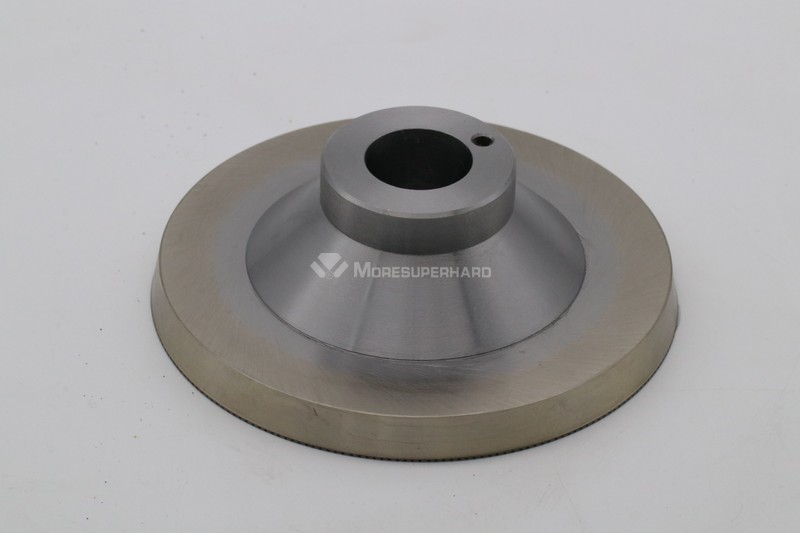

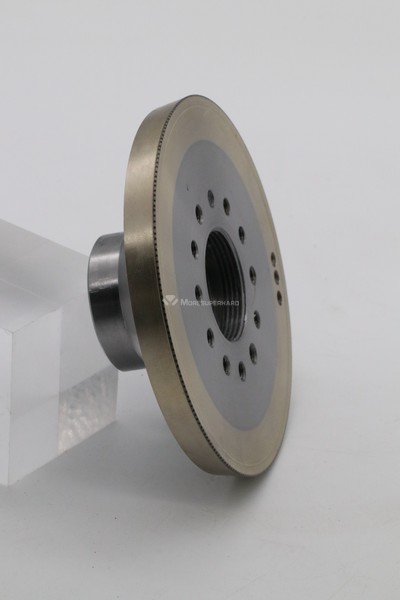

Diamond rotary grinding wheel manufacturer

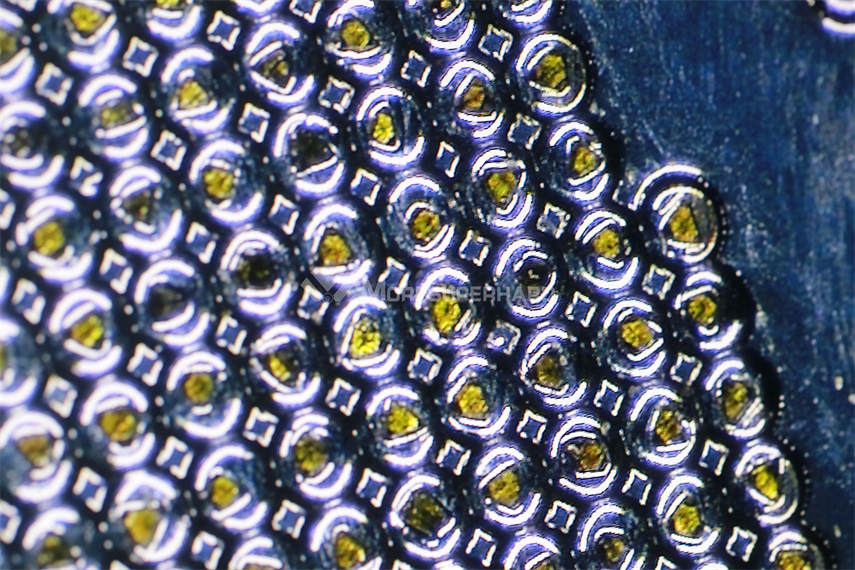

More Superhard Diamond rotary grinding wheel consists of a rectangular artificial diamonds arranged and sintered in a cylindrical shape, making this a traverse rotary dresser with unusually high dressing frequency reproducibility.

When choosing diamond rotary grinding wheels, consider the following factors

1 Machined workpiece

Mainly includes workpiece name, material, heat treatment state, technical requirements, machining allowance (radial, axial, etc.), and machining accuracy

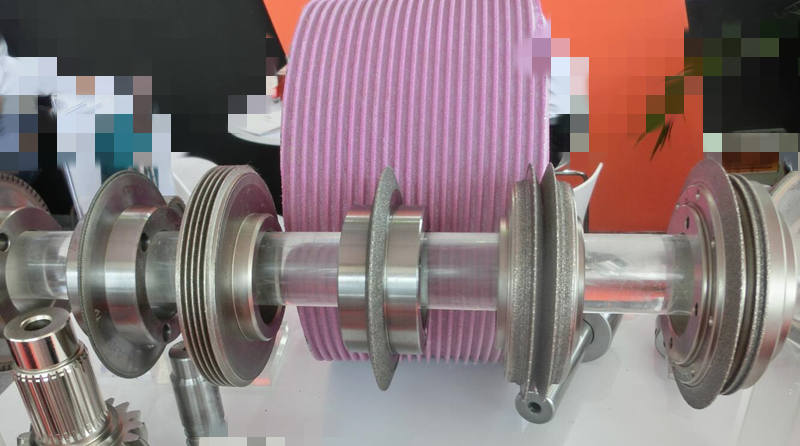

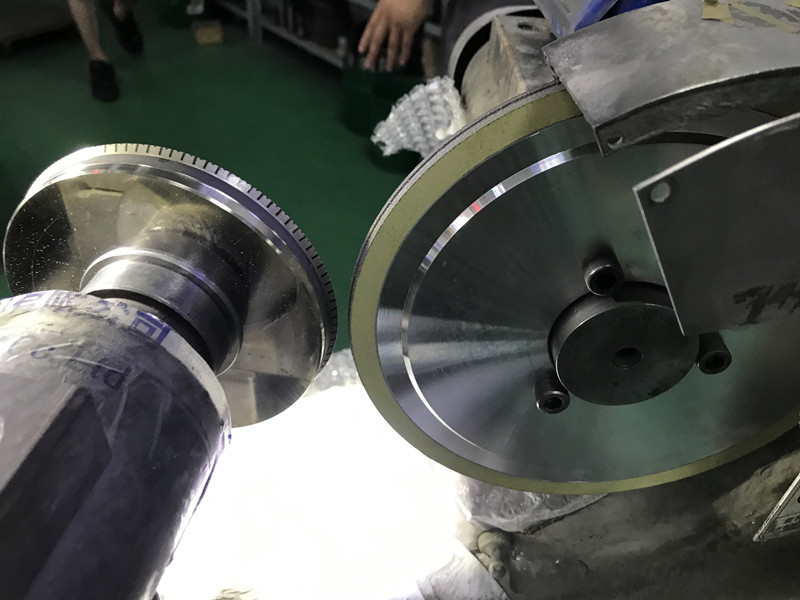

2 Machine tool

To learn about the machine tool manufacturer, machine model, machine type(external cylindrical grinding, surface grinding, crankshaft grinding, bearing grinding, etc.), especially to learn about the application objects of machine tool, processing methods and machining accuracy.

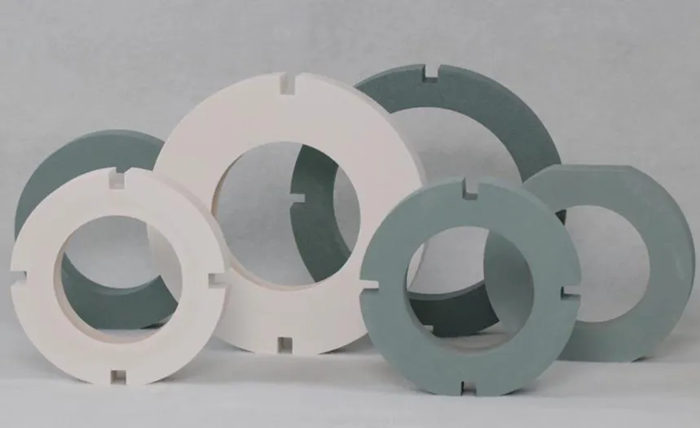

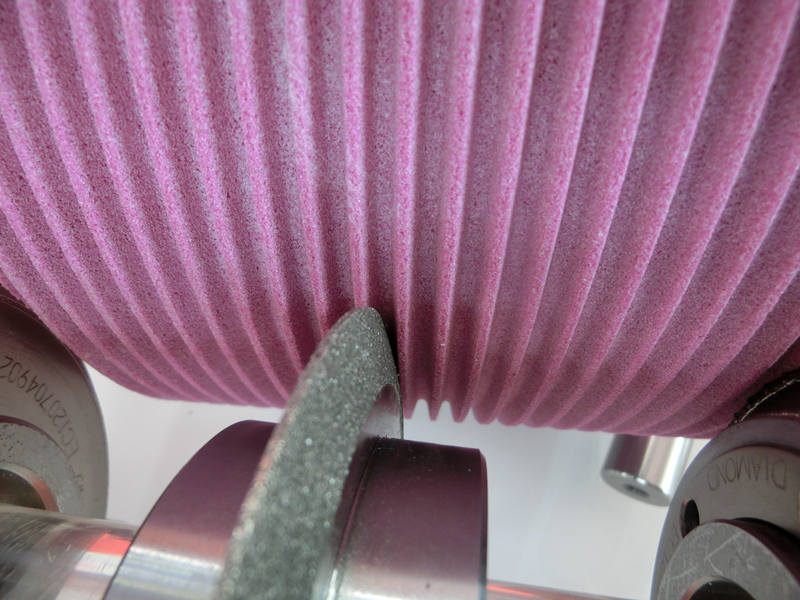

3 Grinding wheel

Select the size( outer diameter, thickness, bore diameter) of the grinding wheel and other technical parameters( abrasive, grain size, hardness, bond, linear velocity, etc.)

4 Driving equipment

If the machine tool has the driving equipment, pay attention to the size of the diamond rotary dresser ( max diameter, width, bore diameter). If there is no driving equipment for the machine tool, taking into account the dressing clamp, processing method and the size of the diamond rotary dresser.

5 Grinding parameters

It includes the linear velocity of grinding wheel, RPM of the workpiece, feed amount, feed speed, dressing cycle, grinding coolant, and etc.

6 Dressing position

It should be reasonably selected according to the actual situation.

Features of Diamond rotary grinding wheel

- Revolutionary dressing consistency:

The rectangular shape of the diamonds is good for wear tolerance, making consistent dressing possible with minimal variation due to edge wear. - Higher-quality machined goods:

Thanks to improved precision in shaping wheels, superior dimension accuracy, surface roughness and roundness can be obtained. - Lower grinding costs:

Rectangular diamonds provide superior longevity to natural diamonds, making it possible to reduce grinding costs.