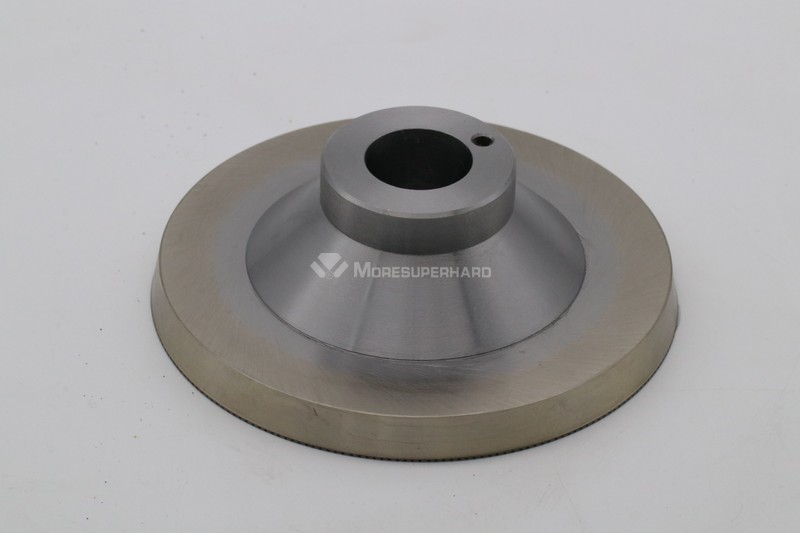

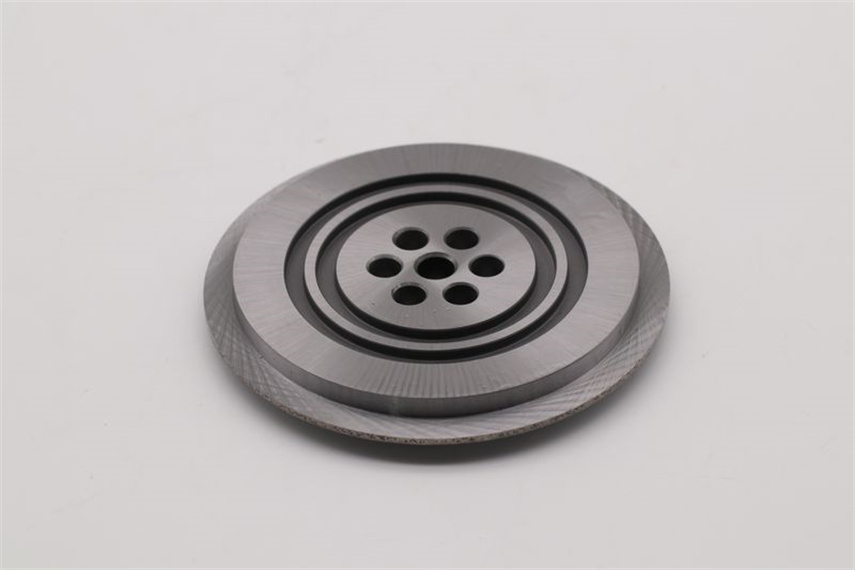

World top cone type diamond dresser

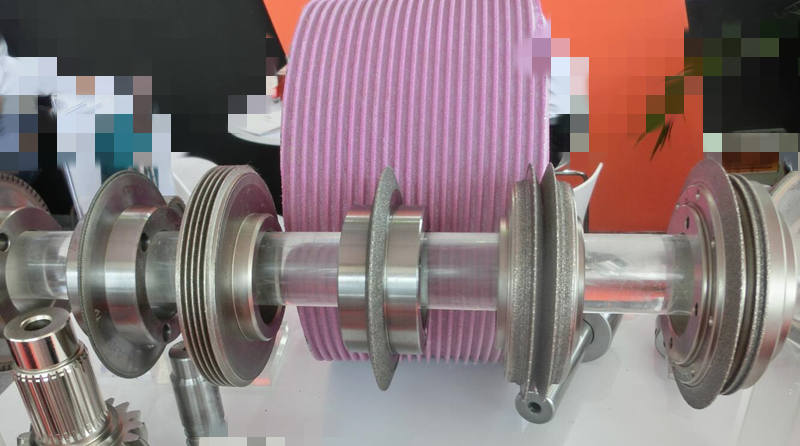

Diamond dressing tools mainly include diamond pens, diamond blades, diamond rollers and diamond abrasive belts.

Contact US

Get Price

Share:

Content

Under what circumstances does the grinding wheel need to be trimmed by diamond dresser?

- Skidding. After the grinding wheel loses the cutting force, it becomes a flat surface, just like the tire tread is ground, and loses friction. In this case, slipping is easy to occur.

- Burns. Burn is a serious situation in which the grinding wheel loses cutting force. This situation often occurs when the cutting force disappears due to blockage of the air hole, and it needs to be repaired immediately.

- Vibration/noise. This condition is another phenomenon that accompanies slippage. Because there is no friction, the grinding wheel surface cannot effectively contact the workpiece. In addition, if the roundness of the grinding wheel is lost and unevenness occurs, it will also vibrate, even Therefore, noise is generated and the size is not precise; the loss of dimensional accuracy indicates that the grinding wheel has lost the cutting force to a very serious degree and needs to be repaired immediately.

- There are scratches or abnormal grinding lines on the surface of the workpiece. If the surface of the workpiece is scratched, it means that the self-sharpening ability of the grinding wheel has begun to decrease, and the abnormality of the grinding pattern usually also indicates that the performance of the grinding wheel has begun to fail.

Inquiry

More Rotary dressing roll, dressing tools