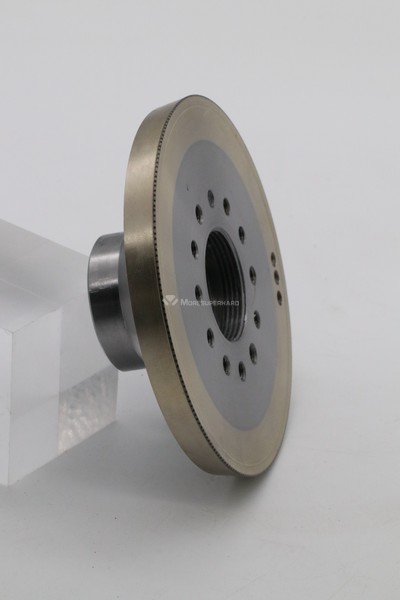

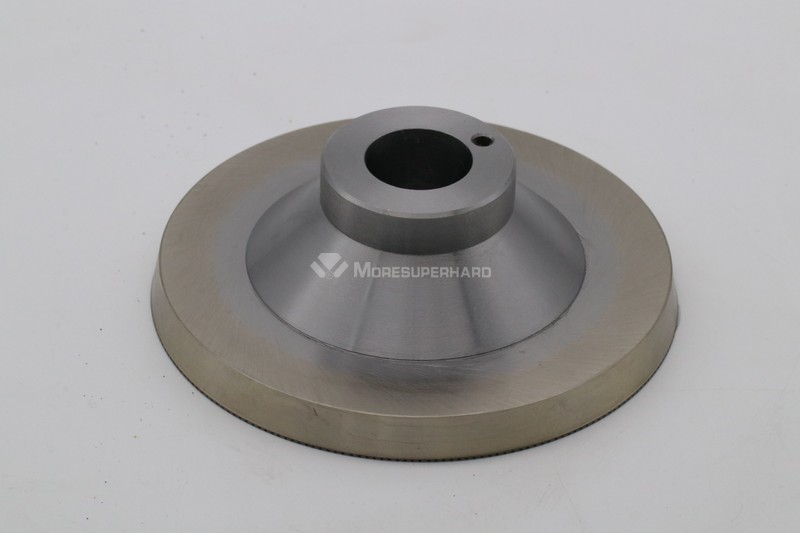

High Precision roller diamond dresser manufacturer

Roller diamond dresser manufacturing methods include: hand sintering method, random arrangement sintering method, electroforming method, etc.

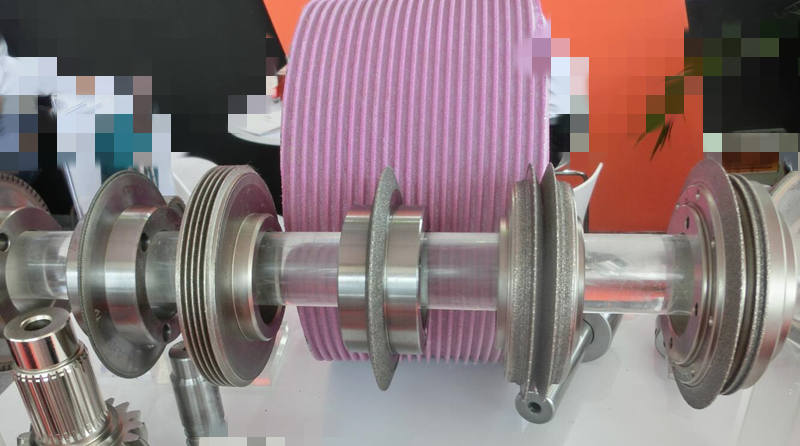

Diamond roller dressers are used in: bearings, auto parts, textile machinery, aerospace and other industries

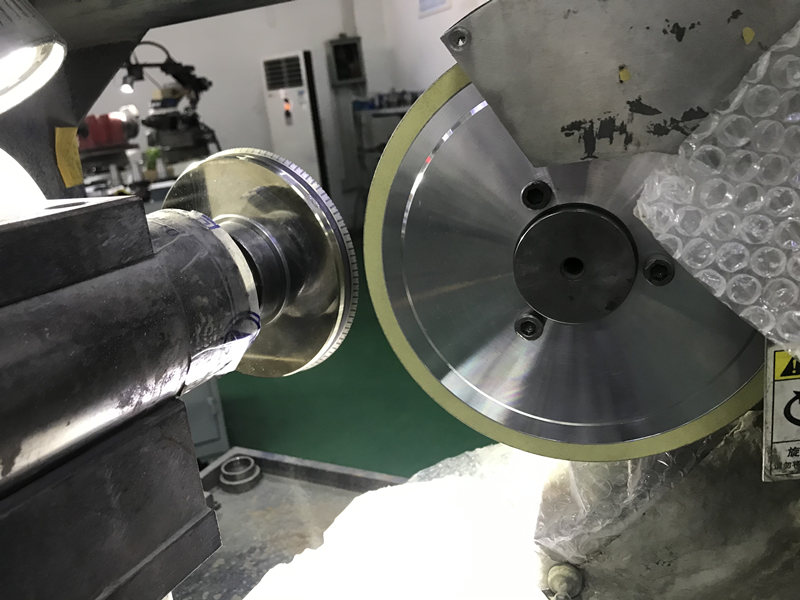

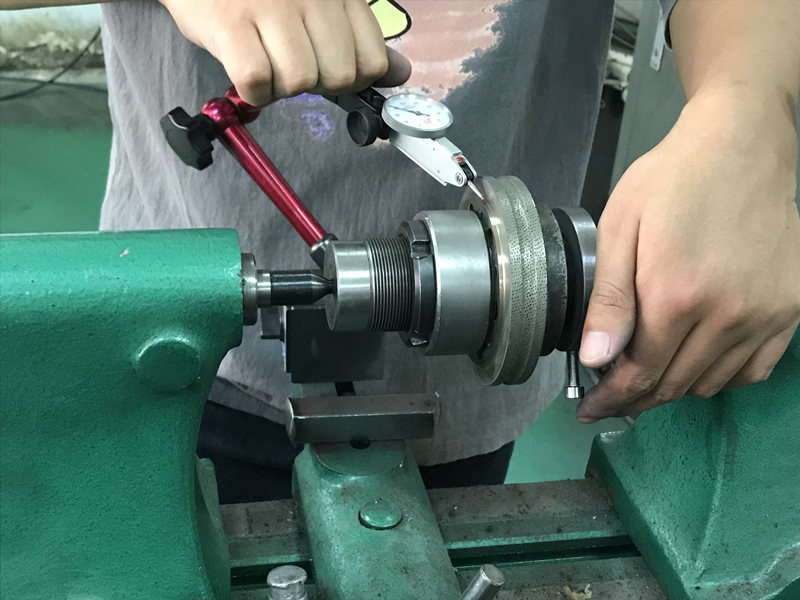

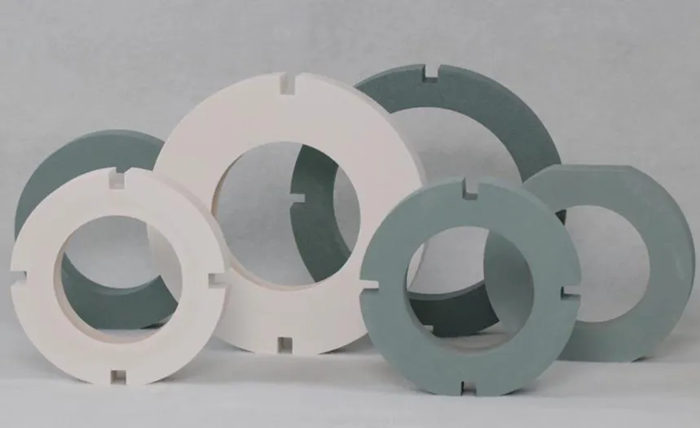

The contour shape, size and accuracy of the diamond roller are designed and manufactured according to the corresponding technical requirements of the processed parts, and the installation size is determined by the structure or requirements of the user’s machine tool.

Roller diamond dresser manufacturing methods include: hand sintering method, random arrangement sintering method, electroforming method, etc.

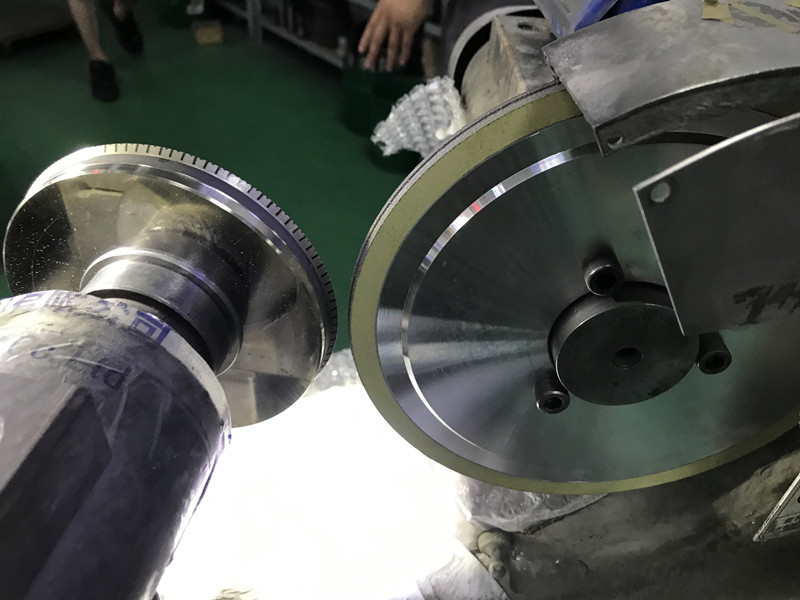

The Roller diamond dresser is suitable for: plunge dressing and CNC trajectory dressing

Roller diamond dresser are used in: bearings, auto parts, textile machinery, aerospace and other industries

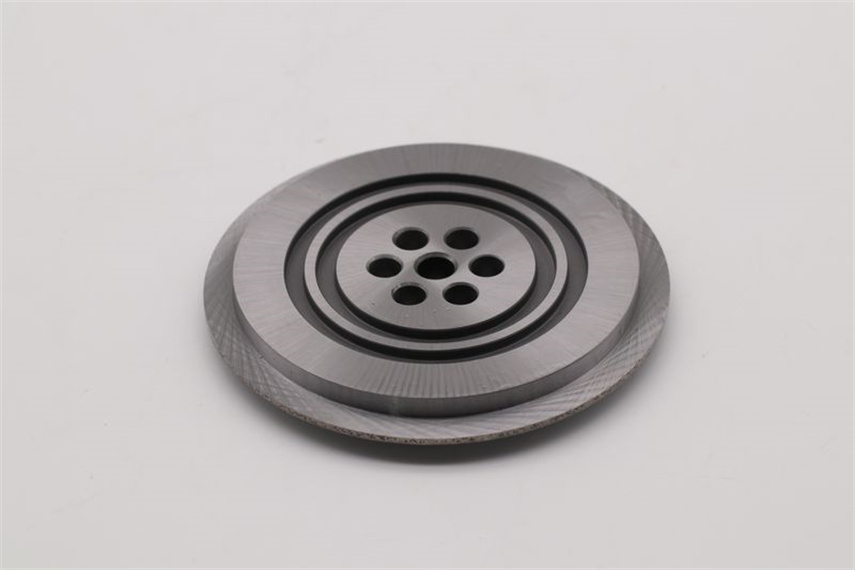

According to different manufacturing process methods, diamond roller dressers can be divided into

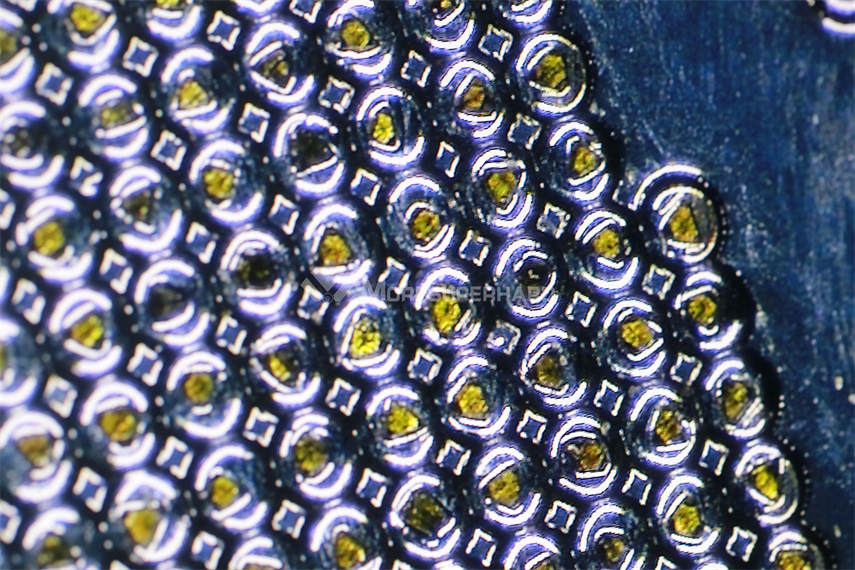

HNT sintered diamond roller: It can be subdivided into two types, hand-planted sintered roller and randomly distributed sintered roller, with strong durability;

HNT electroplated diamond roller: high precision, can manufacture small and complex shape rollers;

CVD diamond roller: new material, good dressing effect on CBN grinding wheel.