Rotary profile dresser, dressing wheels manufacturer

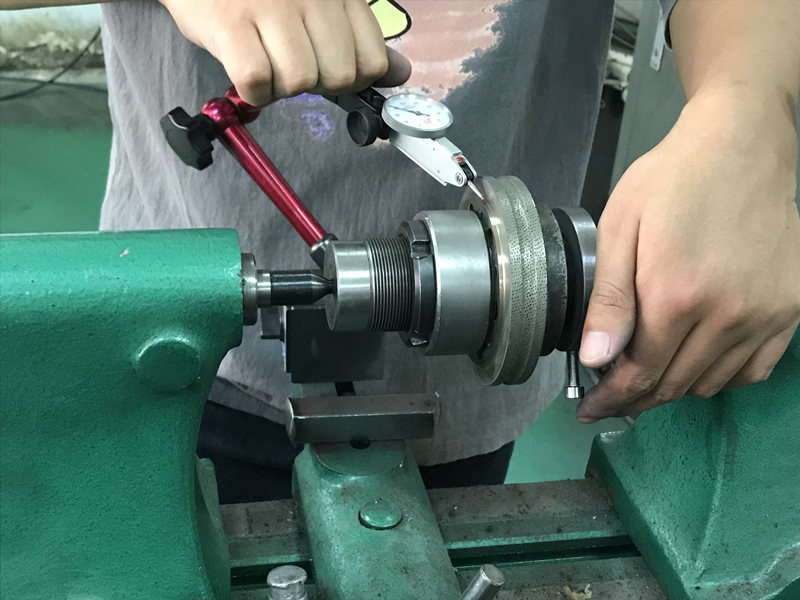

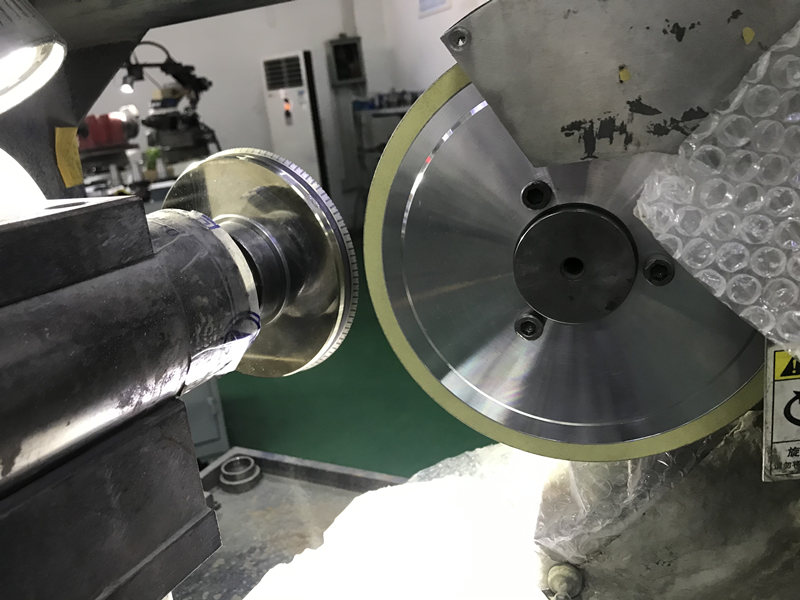

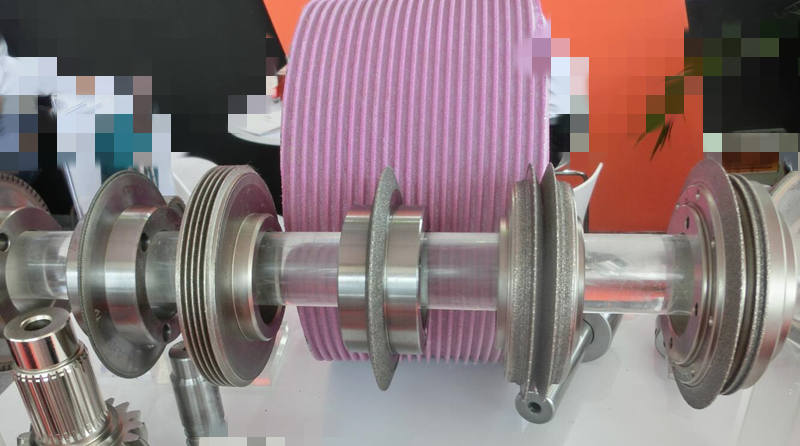

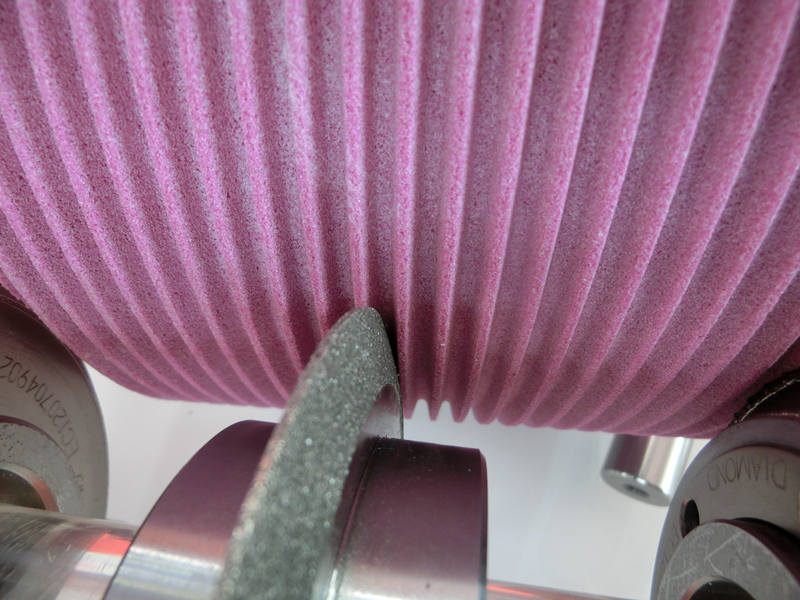

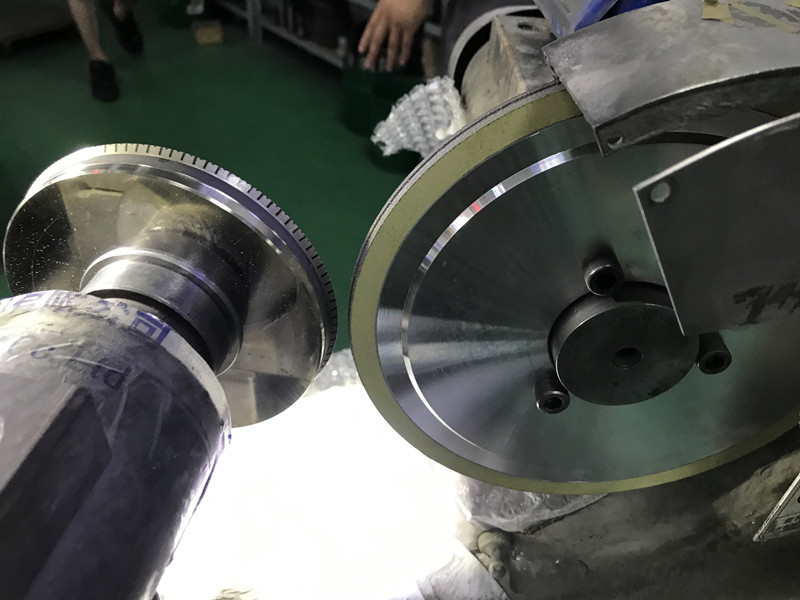

The ordinary ceramic grinding wheel or CBN grinding wheel is trimmed by the rotary profile dresser installed on the grinder, and the part is ground after the grinding wheel is formed, there by copying the contour, accuracy and size of the rotary profile dresser to the processed part through the grinding wheel surface.

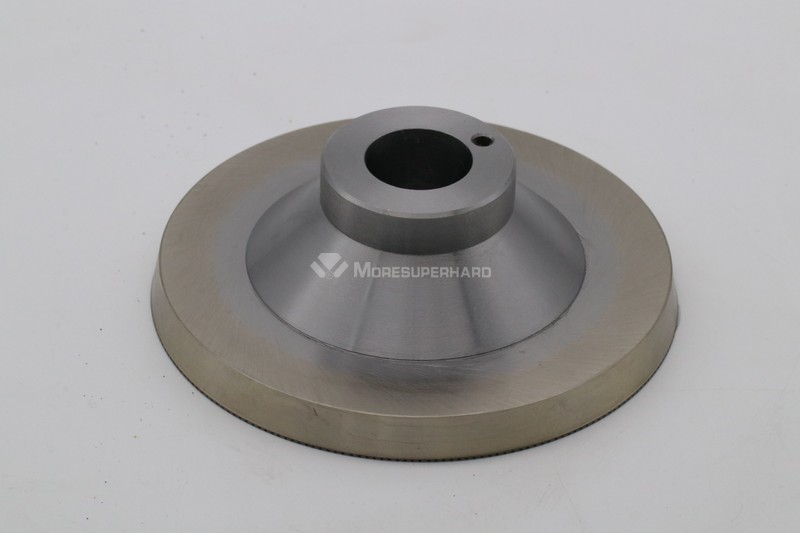

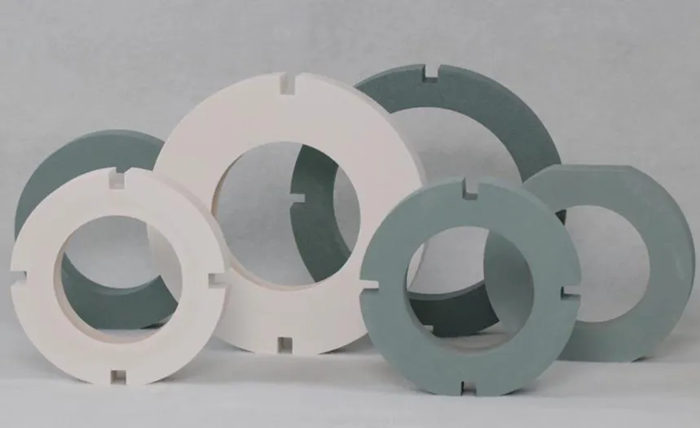

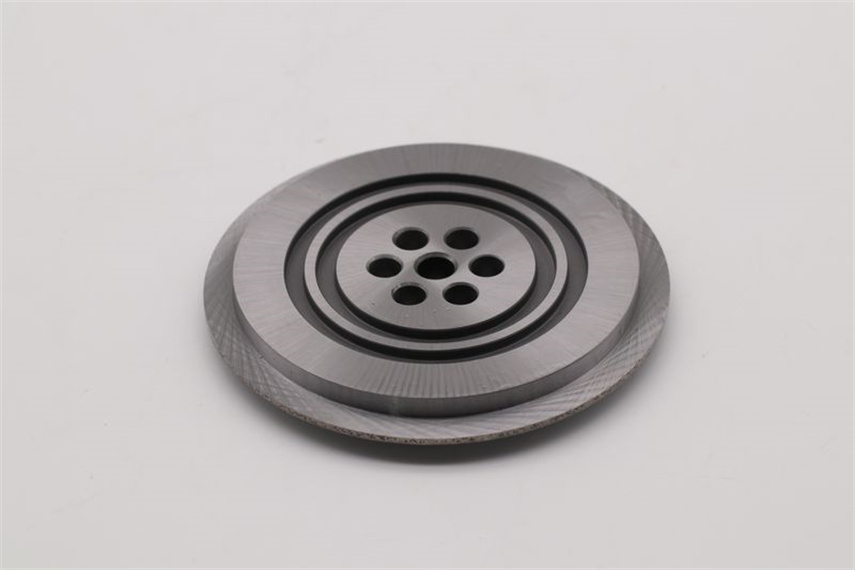

Rotary profile dresser (diamond rollers or rollers) are high-efficiency, long-life and low-cost grinding wheel forming and dressing tools used for mass forming and grinding.

The working principle of the diamond roller is: the ordinary ceramic grinding wheel or CBN grinding wheel is trimmed by the diamond roller installed on the grinder, and the part is ground after the grinding wheel is formed, thereby copying the contour, accuracy and size of the diamond roller to the processed part through the grinding wheel surface. It is characterized by simple operation of the machine tool, low technical requirements for the operators, good consistency of the processed products, and stable quality, which can significantly improve production efficiency and product quality, reduce manufacturing costs, and easily realize grinding processing automation. Compared with the traditional single-point diamond pen dressing, the production efficiency is greatly improved, and the surface quality and precision of the processed parts are higher, which is especially suitable for high-precision and mass production.