0.5 Carat single point diamond dresser

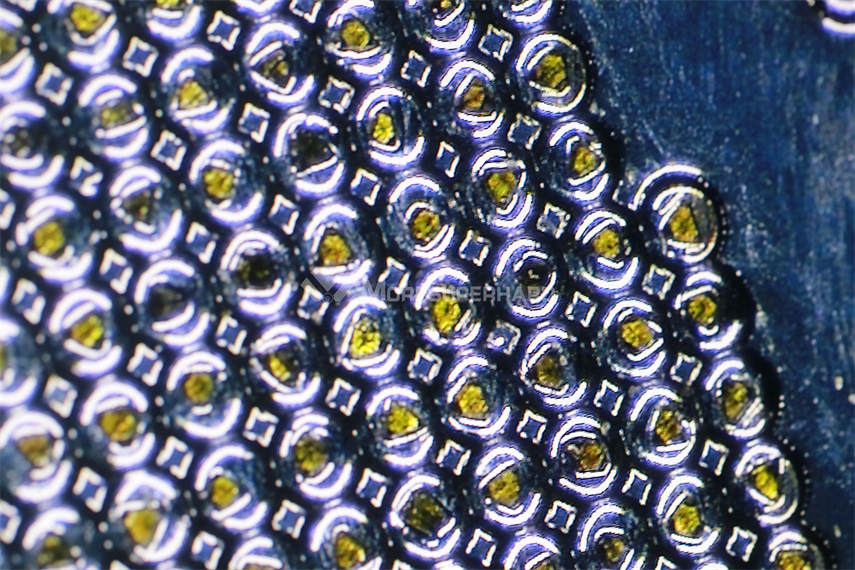

Single-point diamond dresser cone tool – A single-stone diamond is embedded in one shank. This tool is good for complicated forms and radius dressing. As the diamond wears, a flat will develop, resulting in a dull grinding wheel. As a result, frequent rotation of the diamond tool is required.

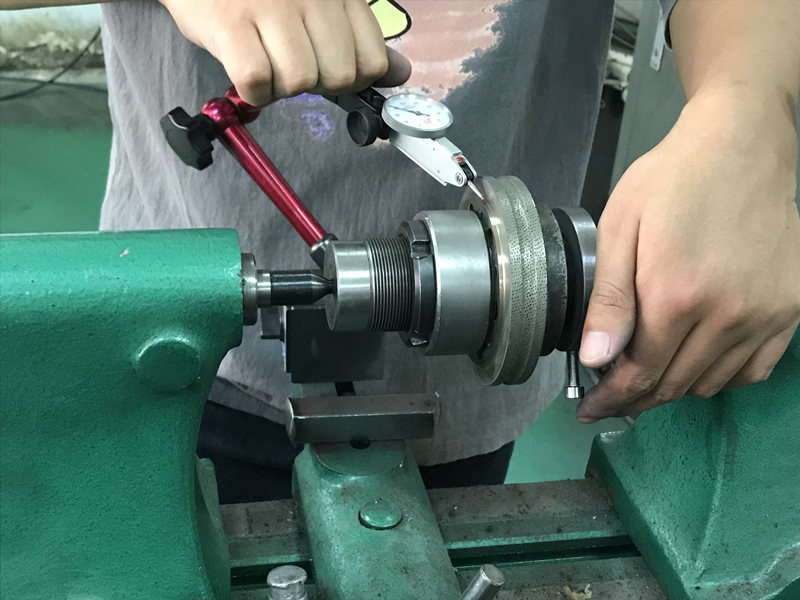

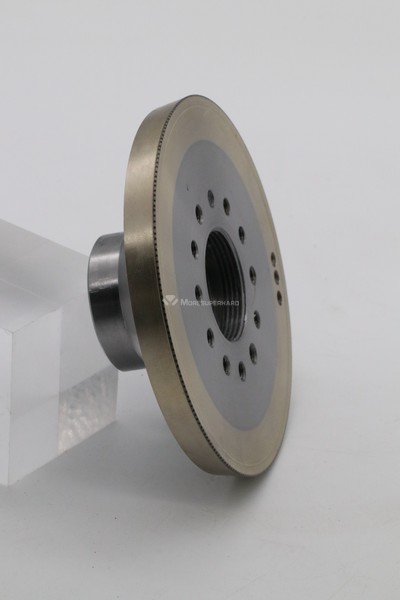

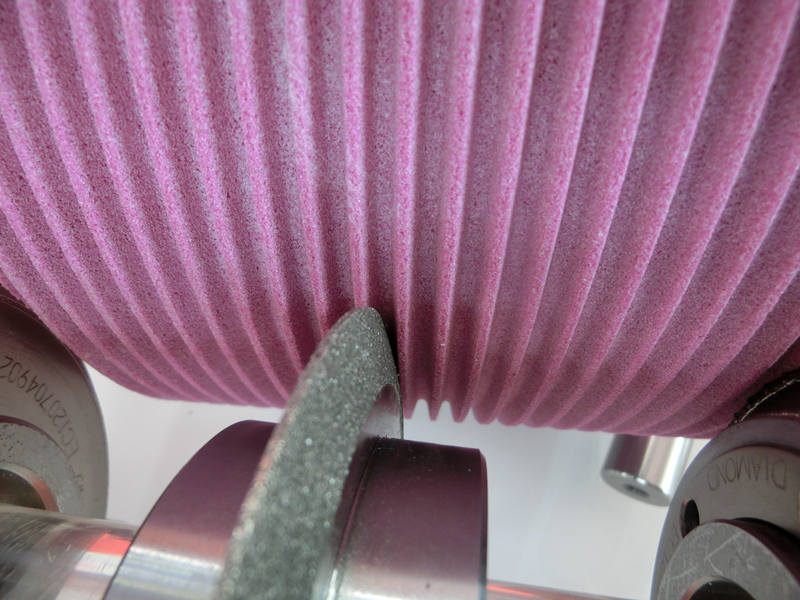

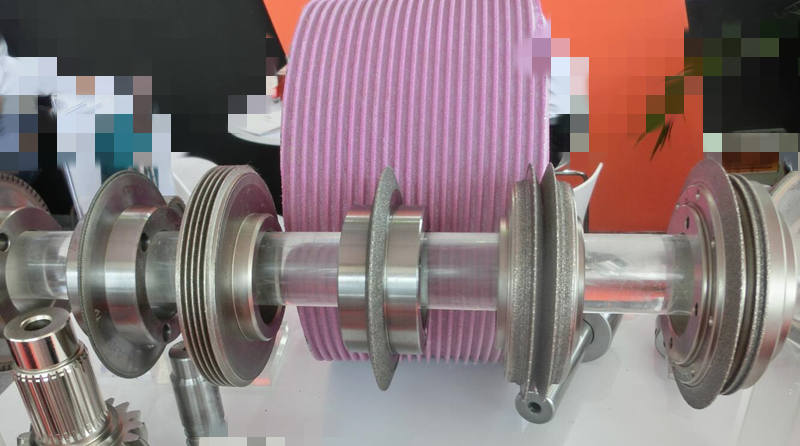

Grinding machine is a common machining equipment. In addition to grinding the surface of the workpiece, it can also process grooves and curved surfaces on the workpiece. When the grinding machine is processing the workpiece, the grinding wheel will wear out. Therefore, after the grinding wheel has been used for a certain period of time, the grinding wheel must be dressed with the aid of a grinding wheel dresser, so that the grinding wheel can regain the shape accuracy and sharpness of the surface.

There are two main types of existing grinding wheel diamond dressers for forming grinding.

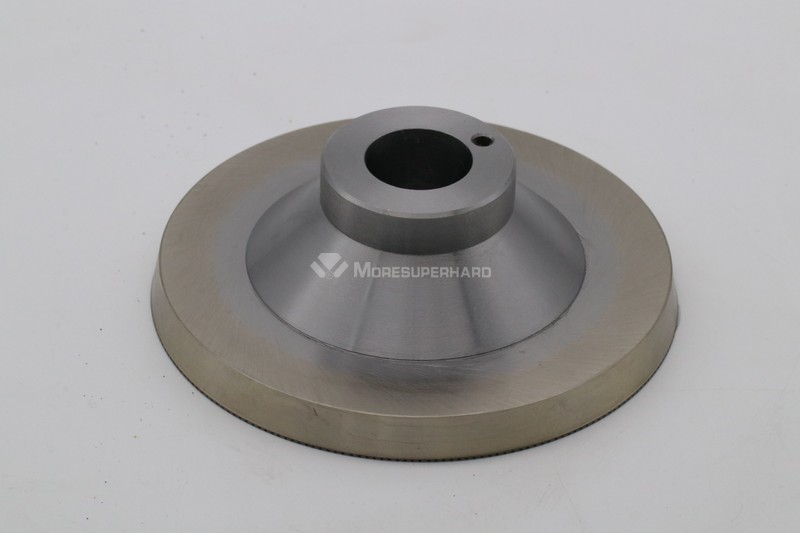

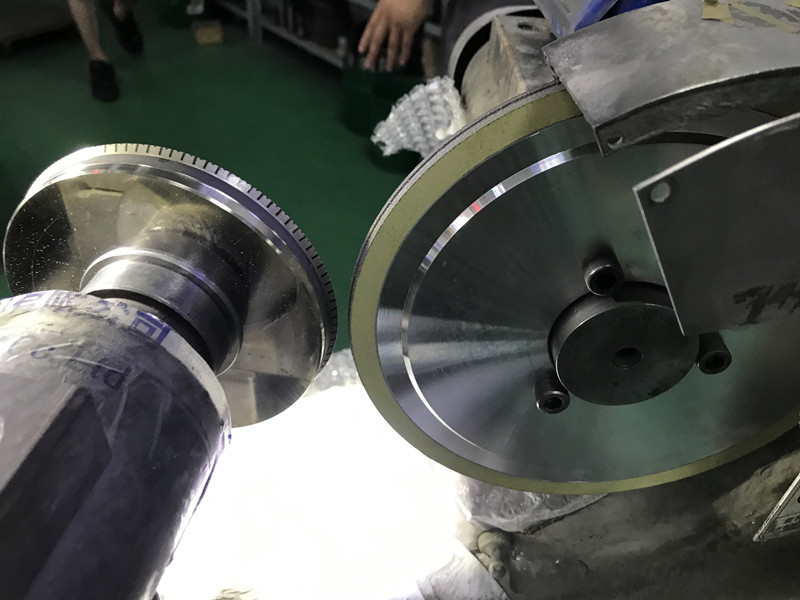

One type is mechanical grinding wheel diamond dressers, which use a pre-made mold that is the same as the processed workpiece, that is, a diamond forming dressing roller or a mechanical mechanism to make the dresser. The dressing pen produces the required movement trajectory to dress a shaped grinding wheel that meets the requirements of the workpiece.

The other type is the CNC grinding wheel diamond dresser, which relies on programming applications to control the movement track of the dressing pen or diamond dressing wheel to dress the grinding wheel. It can rely on the worktable of the grinder to move back and forth relative to the grinding wheel, that is, the dressing tool can only move along the x, y axis with the worktable of the grinder. When these dressers are dressing the forming surface of the grinding wheel with a relatively steep curved surface, the dressing pen or the dressing wheel will interfere with the grinding wheel near the left end point, which will seriously affect the dressing accuracy or make it impossible to dress at all. Grinding wheel dressers with complex molding surfaces have been a problem that the industry has tried to solve for a long time.