High precision sintered diamond dresser roller

The high-life precision diamond roller dressing wheel belongs to the machinery industry and is used for shaping complex surface dressing. The precision of the diamond roller can be copied to the workpiece through the grinding wheel

The high-life precision diamond roller dressing wheel belongs to the machinery industry and is used for shaping complex surface dressing. The precision of the diamond roller can be copied to the workpiece through the grinding wheel. How can we quickly understand the principles and matters of the use of the diamond dressing roller. It is a very important work in production, repair, installation and daily maintenance. Next, I will describe it for everyone.

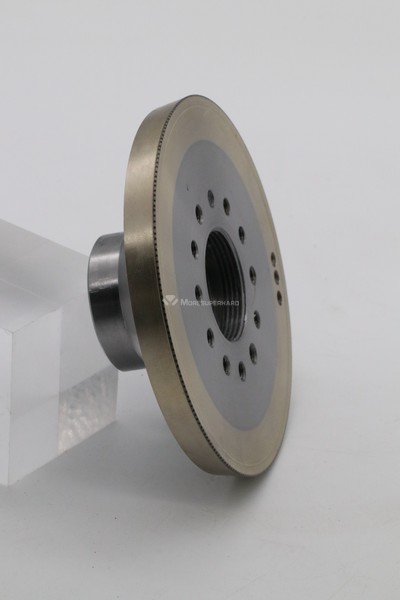

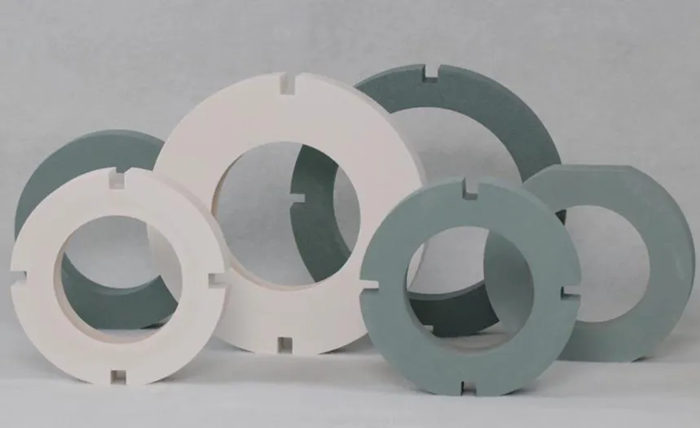

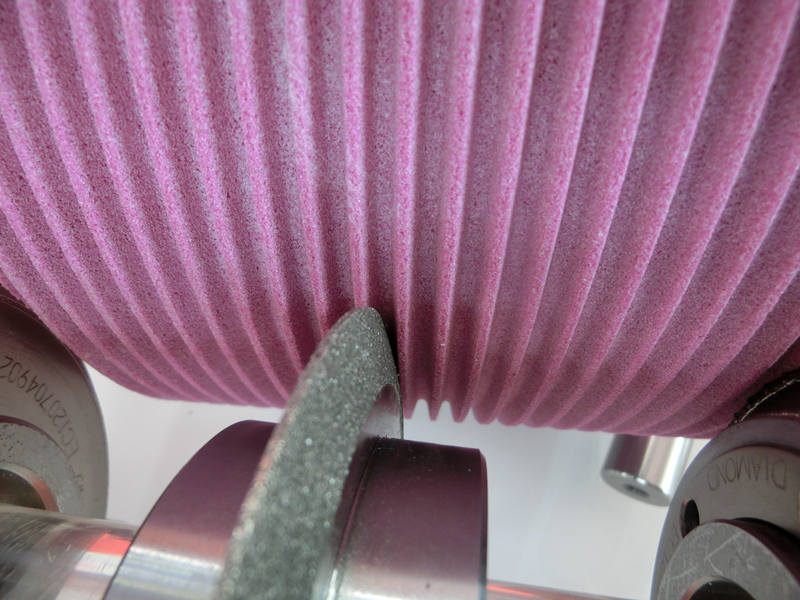

High-life precision diamond roller dressing wheels. High-precision diamond dressing wheels (diamond wheels or rollers for short) are high-efficiency, long-life, and low-cost grinding wheel dressing tools used for mass forming and grinding of special machine tools and gear grinders. It is mainly used for dressing the complex surface of Hundred Corundum and Silicon Carbide Grinding Wheel. Now diamond rollers are beginning to be used in the field of profile grinding.

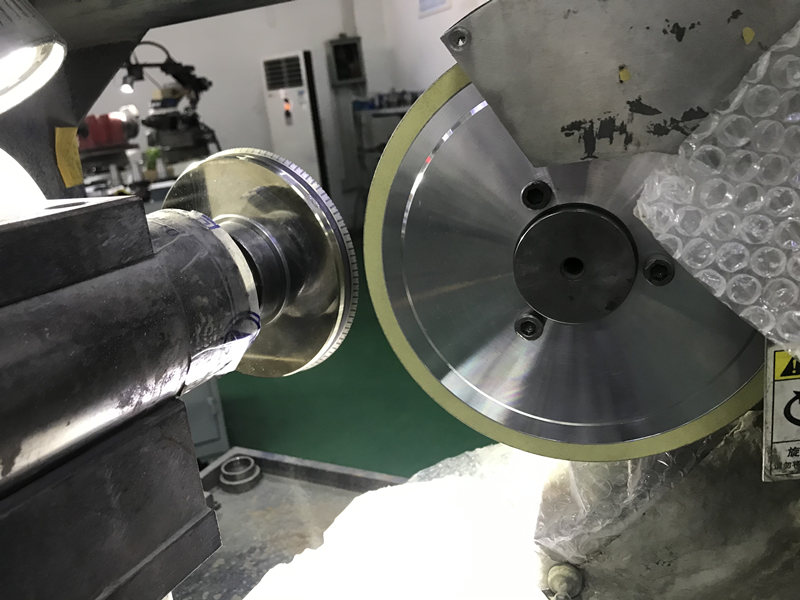

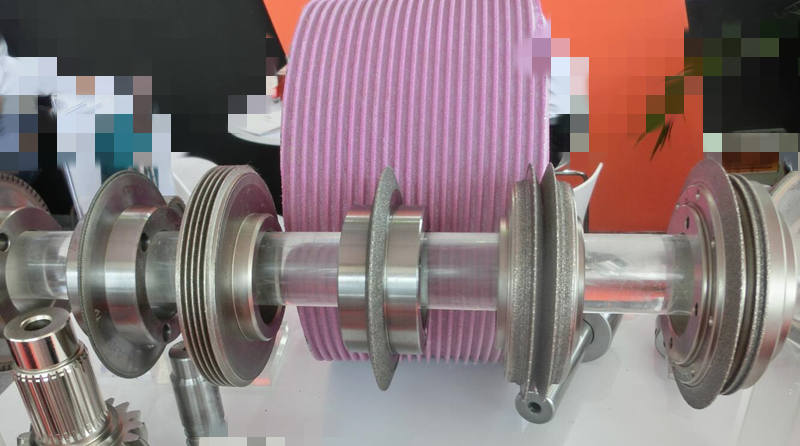

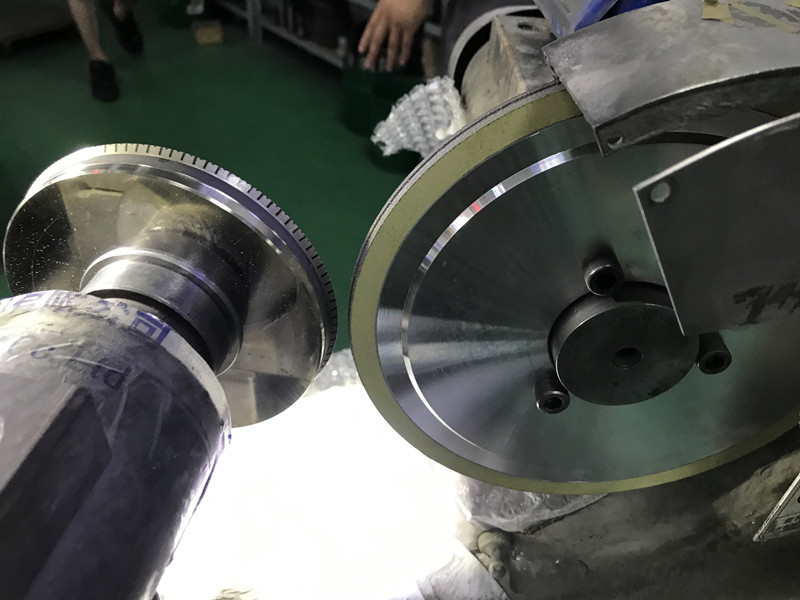

High-life precision diamond roller dressing wheels The working principle of diamond rollers is: by installing on the dressing device of the grinder, the diamond rollers are used to dress ordinary ceramic grinding wheels or CBN grinding wheels. The precision and size are copied to the surface of the processed part through the grinding wheel. It is characterized by simple operation of the machine tool, low technical requirements for the operators, good consistency of the processed products, and stable quality, which can significantly improve production efficiency and product quality, reduce manufacturing costs, and easily realize grinding processing automation. Compared with the traditional single-point diamond pen dressing, the production efficiency is greatly improved, and the surface quality and precision of the processed parts are higher, which is especially suitable for high-precision and mass production.

High-life precision diamond roller dressing wheels. Advantages of diamond dressing rollers for diamond single crystal pens The structure of a diamond pen is generally composed of diamond particles and a handle. The working layer is called the pen tip. The raw material is natural diamond or synthetic diamond, which is diamond The working part of the pen. It looks like a “pen” and later people like to call it “King Kong Pen”. Its advantage lies in abrasion resistance and high dressing efficiency. Diamond dressing rollers are “tailor-made” products. They are designed and manufactured according to the contour shape, size and required accuracy of the parts to be processed, which are similar to grinding wheels. The advantage lies in the simple operation of the machine tool and the technical requirements for the operators. Not high, the processed products have good accuracy and consistency, and the quality is stable, which can significantly improve production efficiency and product quality, reduce manufacturing costs, and easily realize the automation of grinding processing.

High-life precision diamond roller dressing wheels. The following matters should be paid attention to during the use of diamond rollers:

- The user should use a special roller dressing device as much as possible, and ensure that the machine tool and the dressing device have sufficient accuracy and rigidity;

- The fit clearance between the roller and the installation mandrel should be ≤0.005mm;

- The ratio of the linear velocity of the roller to the grinding wheel being dressed is 0.4~0.7;

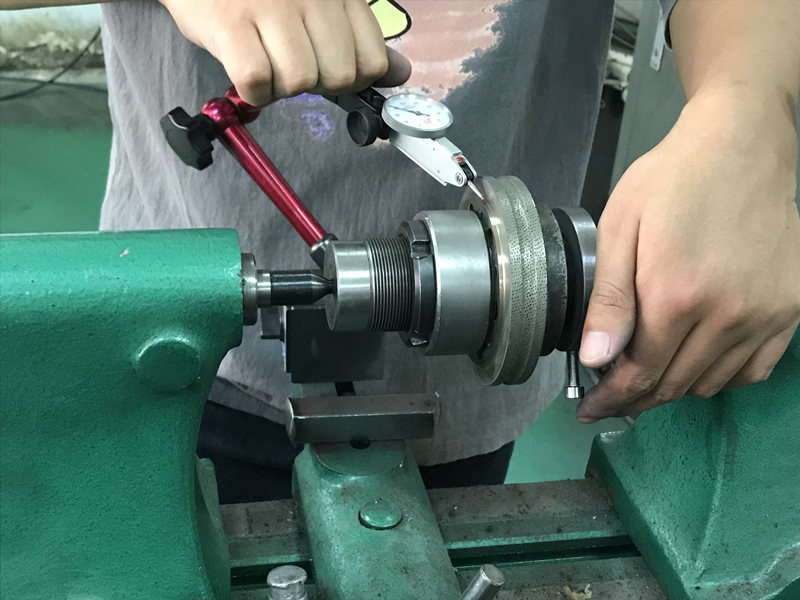

- The user must install the roller correctly and adjust the runout of the roller. After installation, the end runout of the reference end surface of the roller and the radial runout of the reference outer circle should not exceed 0.002mm;

- When installing and disassembling the roller, it is strictly forbidden to knock the roller directly to prevent the profile or datum of the roller from being damaged;

- When the roller is dressing the grinding wheel, it should be ensured that the roller has reliable and sufficient cooling;

- When dressing, avoid the impact of the grinding wheel on the roller, so as not to damage the accuracy of the roller;

- In order to prolong the life of the roller, when the roller is dressing the grinding wheel, the feed amount of each dressing should not exceed 0.02mm as much as possible;

- When the roller is not rotating, the rotating grinding wheel cannot be touched and trimmed, which will result in the loss of the accuracy of the roller;

- If there is something unclear during use, please contact the manufacturer in time, do not process or modify the roller, so as not to cause loss of accuracy of the roller

Long-life precision diamond roller dressing wheels can be customized according to customer drawings to meet customer precision requirements. Our customers are all over the country and abroad, and we provide high-quality after-sales services to our suppliers.