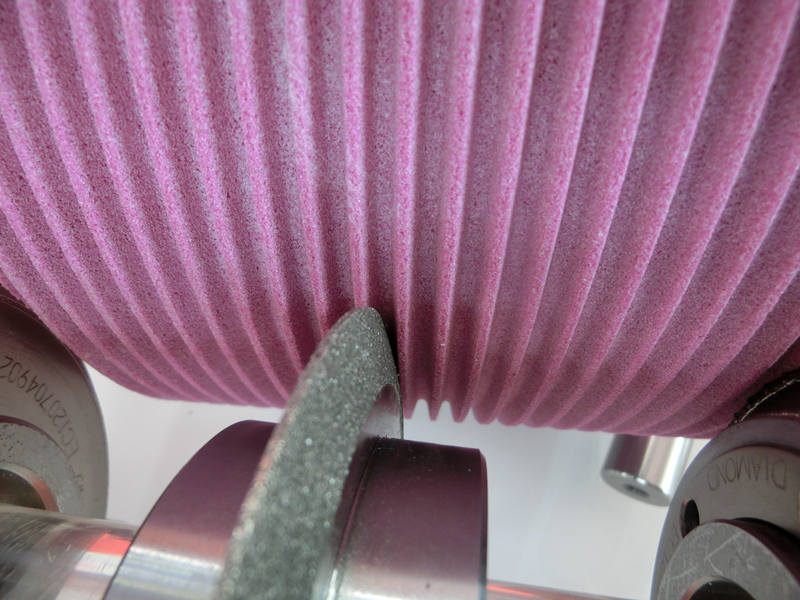

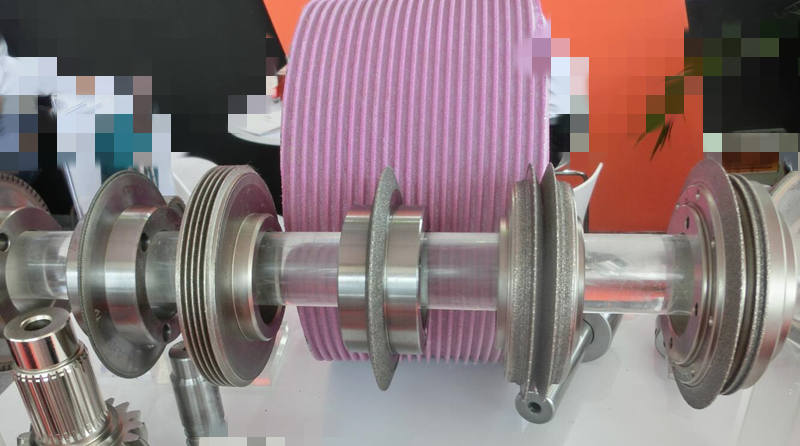

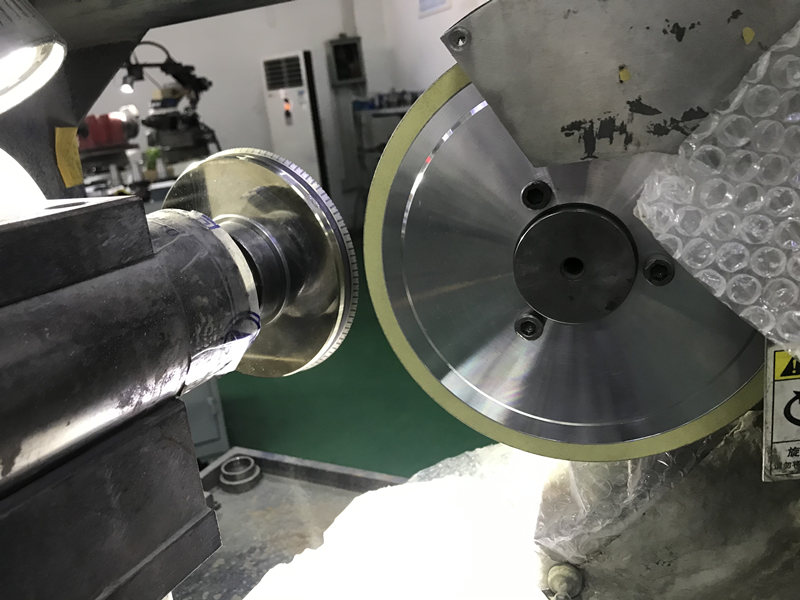

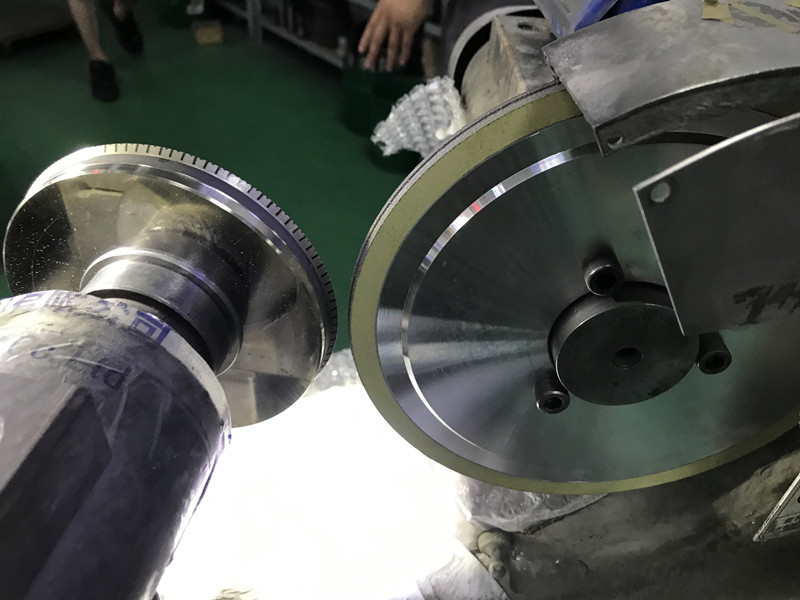

High precision rotary diamond dresser

The high precision rotary diamond dresser is used for dressing grinding wheels ( vitrified cbn grinding wheel, conventional grinding wheel).

Contrail CVD Sintered Dressers

The basic principle is to change the original single point of the original diamond dresser into rotary dresser trimming, which is divided into swing type and fixed type according to the dressing tool dressing method. Most of the common ones are fixed, and they are moved and trimmed according to a certain trajectory to repair the partial surface.

Application industries:Automobile engine, Machinery industry, Robot parts, Vitrified CBN wheel, Flute dresser

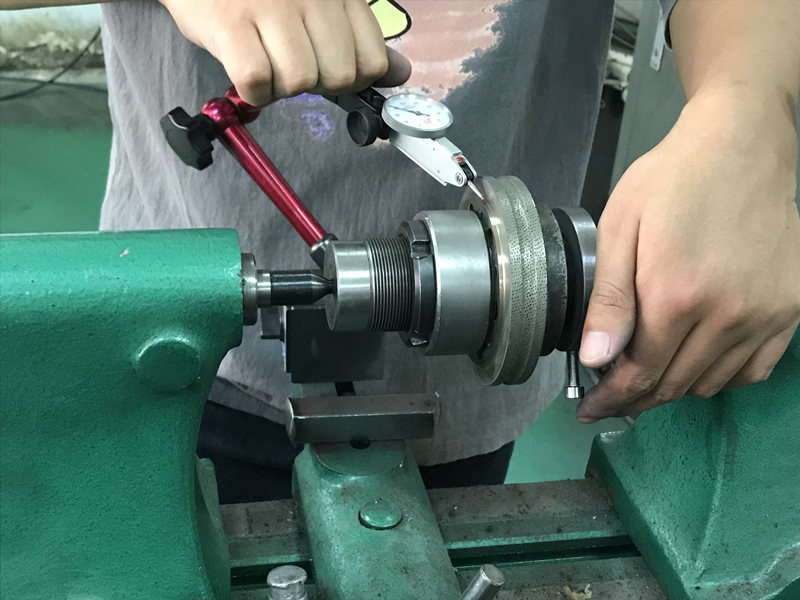

Hand Setting Dressers

Here selected diamonds are applied to the negative profile by hand using an adhesive and in accordance with a defined pattern. By varying the distances between the diamond grits, it is possible to achieve the optimum arrangement of diamonds needed to ensure the required surface finish later in the workpiece.

Application industries: Turbine blade, automobile valves, crankshafts, sewing industry

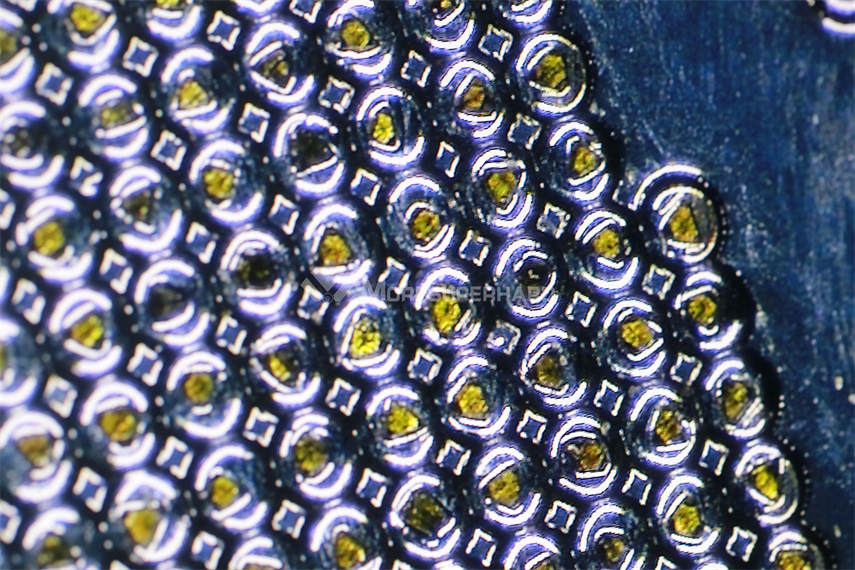

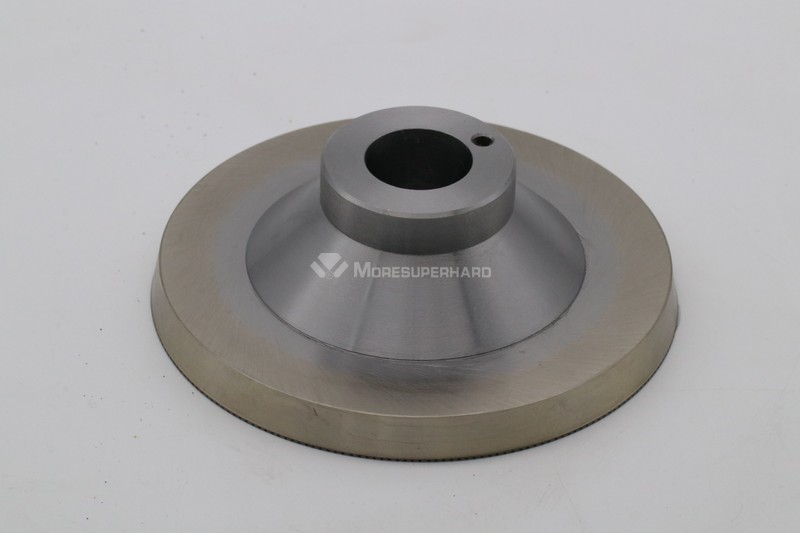

Reverse Plated Dressers

The diamond grit size, selected to correspondto the smallest convex profile radius, subsequently determines the surface finish of the workpiece to be ground so that small radii and relative coarse surface qualities do not correlate.Here the diamonds are packed next to each other as densely as possible in a stochastic distribution. This is beneficial for the tool life of the roll but also leads to increased dressing forces.

Application industries:Turbine Blade – Fir tree root form, cam grinding, bearing industry, ball joints,needle injectors