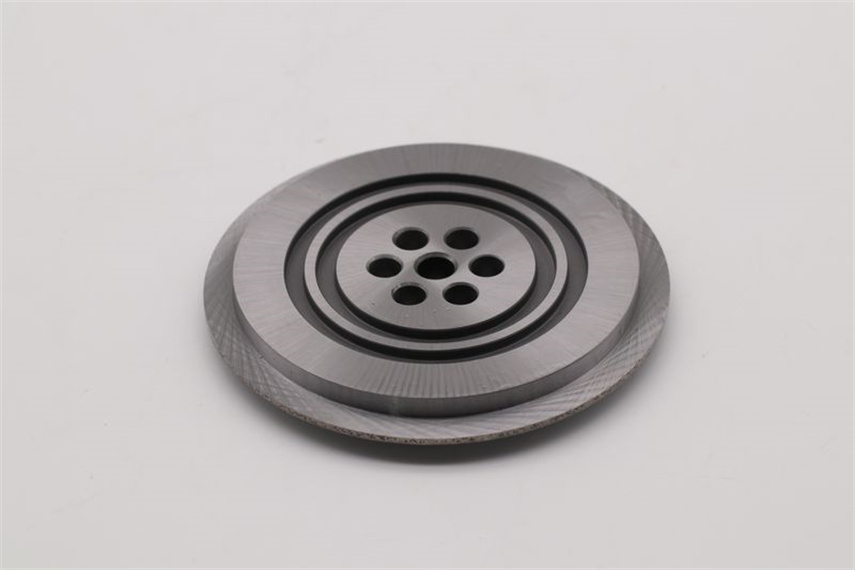

Rotary diamond dresser for bearing grinding

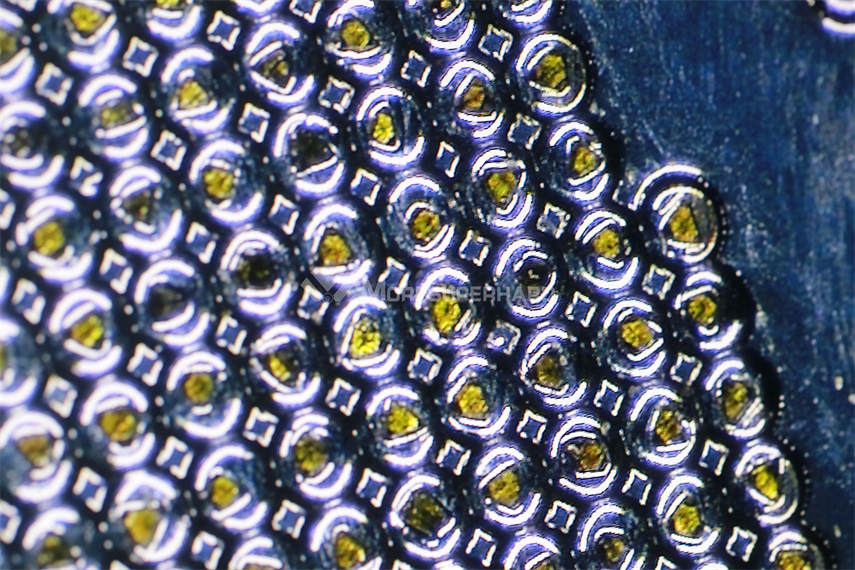

Rotary Diamond Dressers are now recognized as the most efficient and economic means of dressing and truing grinding wheels to the correct form, tolerance and condition. rotary diamond dressers use is growing rapidly in the manufacture of components for automotive, aerospace, power generation, machine tool and precision engineering industries.

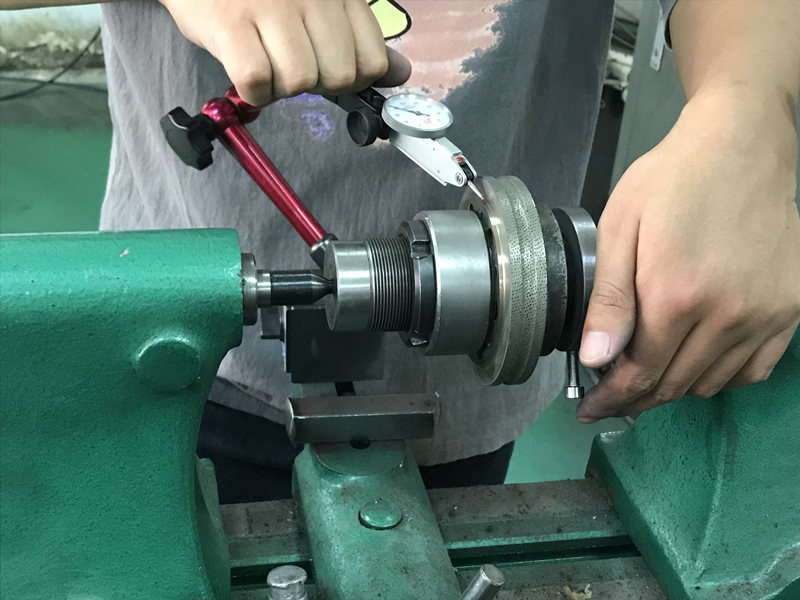

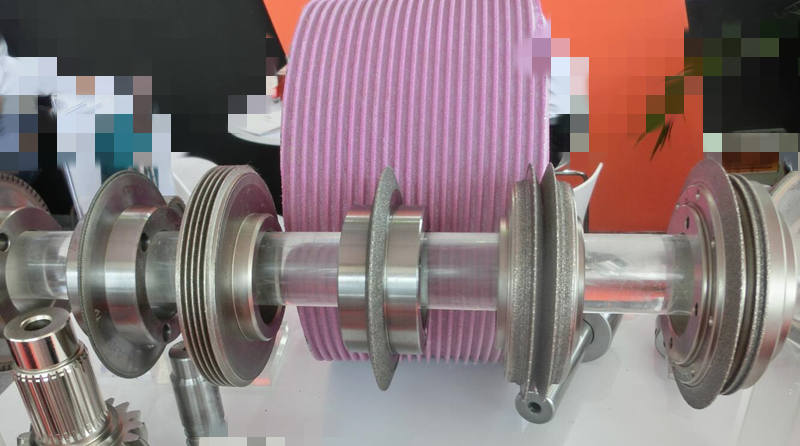

Grinding of guide parts often requires strict control of its profile and roughness. Whether in car pulleys or in complex bearings such as double guide ball bearings, the clearance accuracy and matching rate of the final product often directly affect the customer’s Production and user experience. However, it is clear in the industry that after the grinding wheel is manufactured, it is necessary to perform dressing to grind the workpiece to ensure the accuracy of the workpiece. Previously, the two most commonly used grinding wheel dressing methods-roller dressing and turning dressing were introduced. . I believe that friends who have known it will understand that compared with turning method, roller dressing has higher precision and efficiency and longer service life. Therefore, rotary diamond dresser often used as one of the preferred dressing methods for superhard grinding wheels for grinding precision parts.

Case of Rotary diamond dresser for bearing grinding

| Matter | The accuracy is can’t to achieve of bearing guide |

| workpiece | Double guide ball bearing |

| Grinding method | Form grinding |

| Dressing tool | Single point diamond dresser |

| Require | Contour (+-0.003mm) Ra <0.4 |