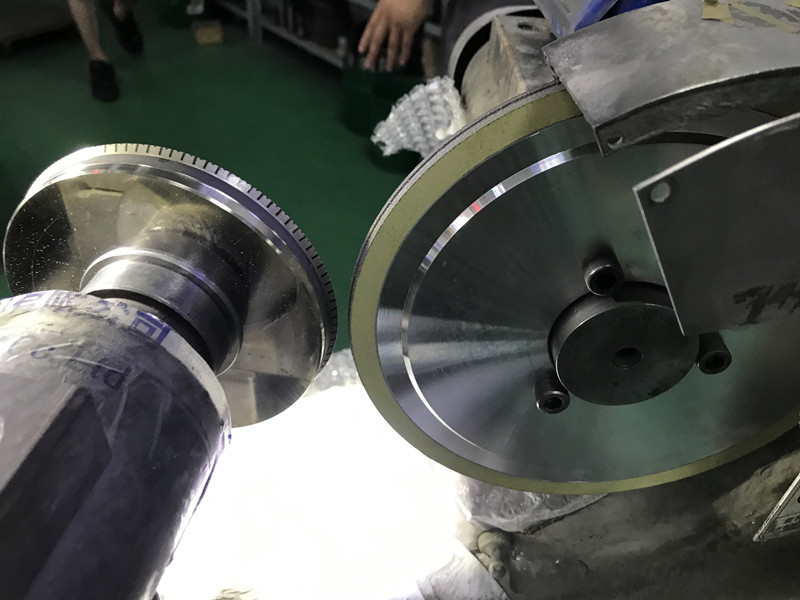

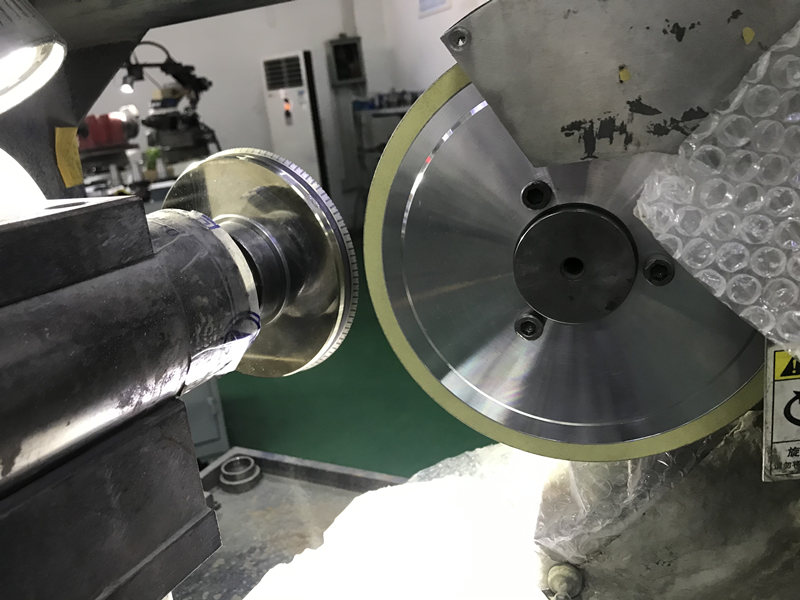

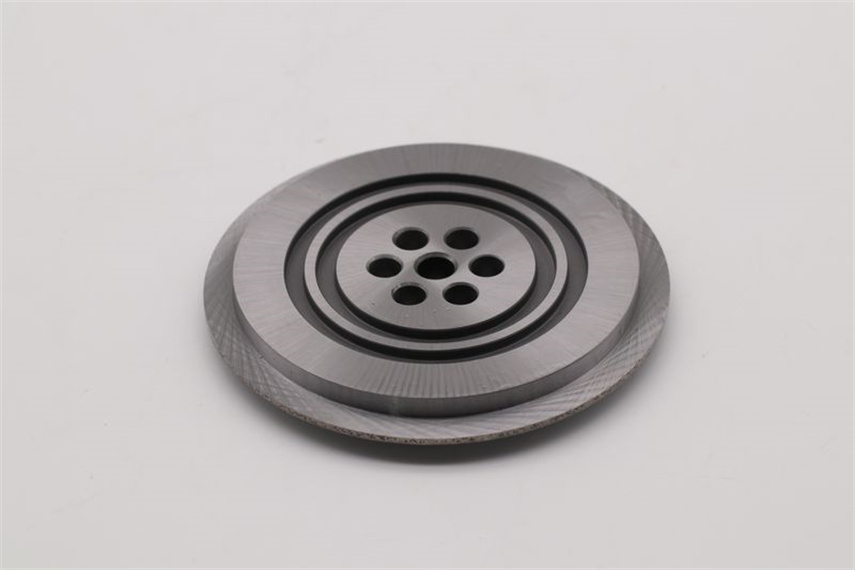

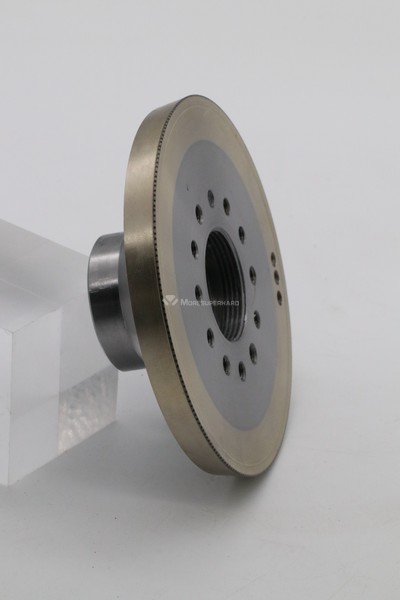

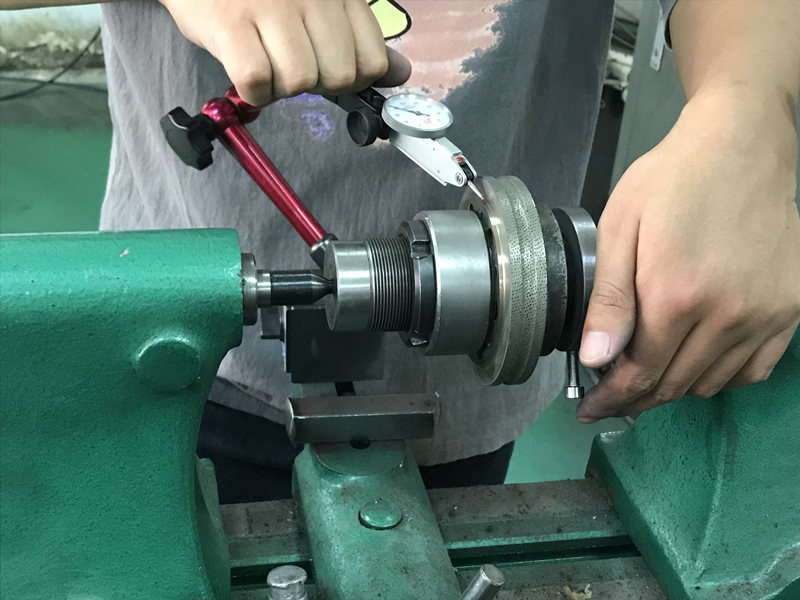

qualified profile diamond dressing rollers

1. High production efficiency, long service life and low cost of dressing of individual parts.

2. It can maintain the stability of parts precision and the high qualified rate of products for a long time.

3. For some parts whose complex surface or other imitation dressing is difficult to meet the requirements, the Rotary dresser can obtain satisfactory results.

4. Easy to operate.

5. High utilization of CNC machine, easy to achieve automation and mass production.

Precautions for using:

1. The particle size of the diamond should be one size coarser than that of the repaired grinding wheel, and it is also necessary to choose diamond particles with similar sizes and spherical shapes, commonly used particle sizes ranging from 36 # to 100 #.

2. Usually, the linear velocity direction at the contact point between the roller and the grinding wheel is in the same direction, and the ratio of the linear velocity of the roller to the linear velocity of the grinding wheel (QD value) should be taken as+0.3~+0.7, which should not exceed+1; When trimming, the cutting amount of the roller is 0.5~1 per revolution of the grinding wheel μ M is appropriate, and the total amount of each grinding wheel trimming should be 0.02-0.04mm; Try to compress the light repair time as much as possible.

3. The manufacturing error of the diamond roller should be less than about 1/2 of the workpiece tolerance, and the fit gap between the roller hole and the installation bearing should be 2-4 μ m.4. Natural or artificial diamonds can be used, and artificial diamonds must use high-strength grade diamonds, such as special diamond SCD for steel grinding or high-strength diamond SMD.

5. When manufacturing rollers, general precision rollers can be manufactured using external plating and sintering methods, while high-precision and complex surface rollers can be manufactured using internal plating methods while undergoing grinding and trimming.

6. When dressing the grinding wheel with diamond rollers, it is necessary to follow the action program of fast forward (not touching the grinding wheel) → slow forward (feeding according to the required cutting speed) → light repair → exit, and do not make mistakes, otherwise the service life of the rollers will be difficult to guarantee.