Distributors for diamond rotary dresser

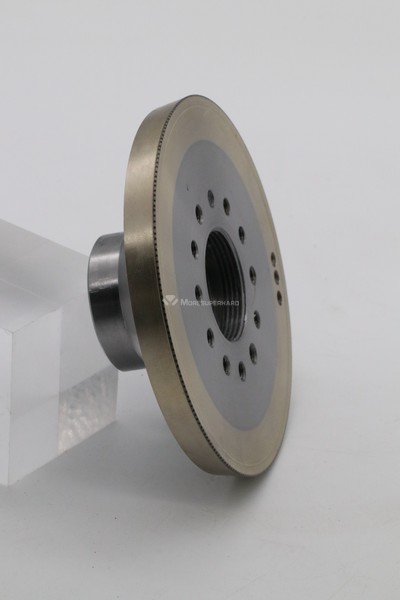

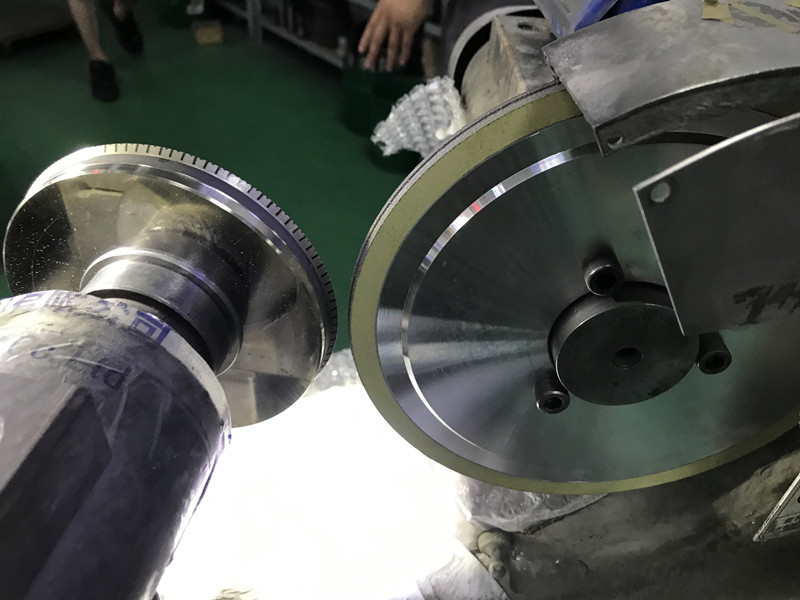

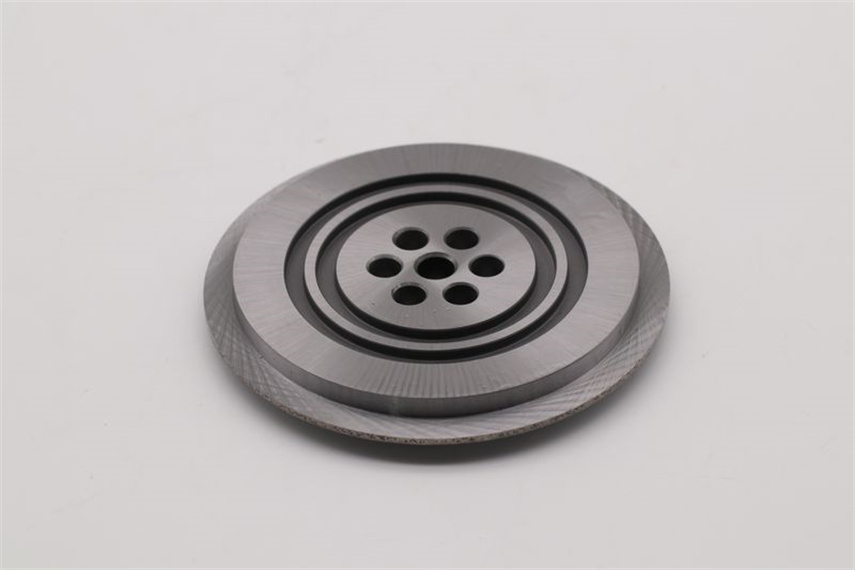

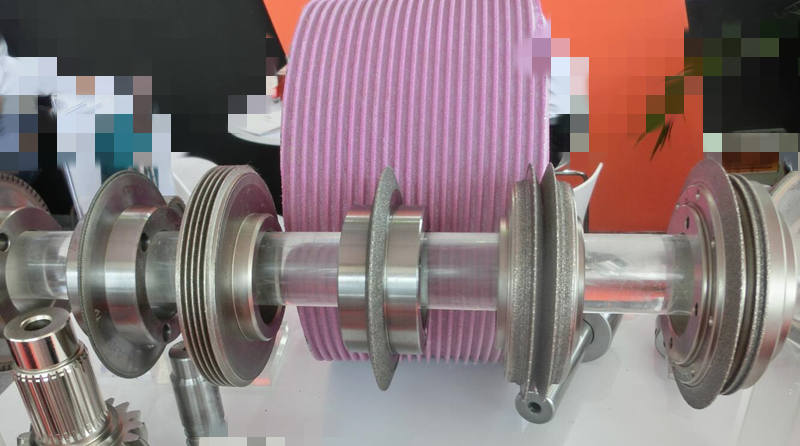

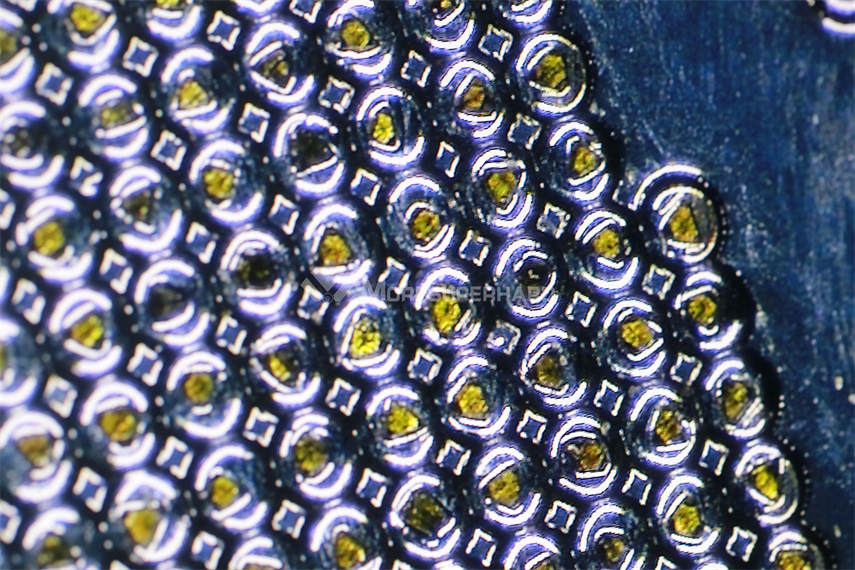

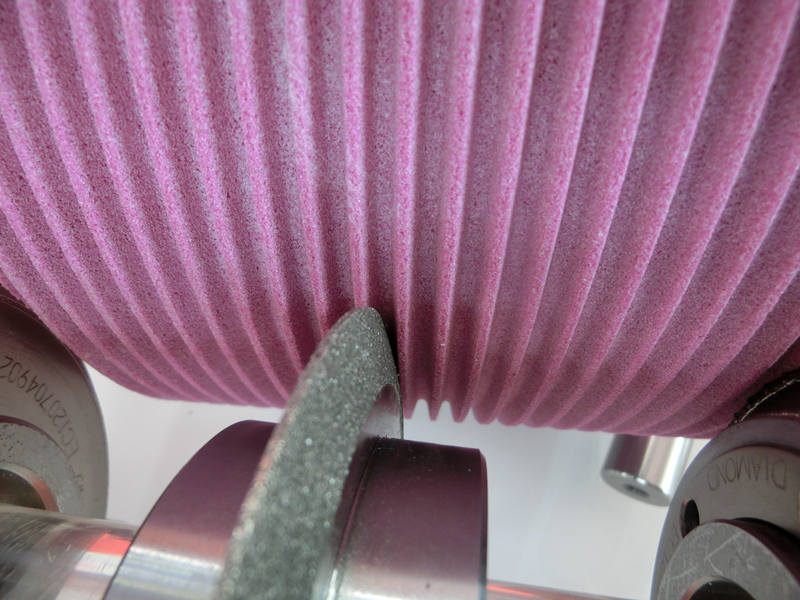

Diamond rotary dresser is a type of the rotary dresser. This is a diamond dresser for gear forming of worm-like general grinding wheels.

High precision ddiamond rotary dresser for the desired grinding application. Also available are CNC dressing wheels with PCD or natural diamonds and gear grinding wheels or custom-built diamond tools for grinding of CBN wheels.

When should I dressing the wheel use diamond rotary dresser?

As mentioned above, the insufficient cutting force caused by passivation and clogging and the unevenness caused by abrasion are directly reflected in the grinding results; therefore, when the following conditions occur during grinding, it is necessary to trim The dressing of the grinding wheel

- Slip: The grinding wheel becomes a flat surface because it loses its cutting force. Just like the tire tread is flattened and loses friction, it is easy to produce slipping.

- Burns: Burns are the most serious situation in which the cutting force is lost. This situation most often occurs in situations where the cutting force is lost due to obstruction of the stomata, and it needs to be dressed immediately.

- Vibration/Noise: This condition is another phenomenon other than slipping. Because there is no friction, the grinding wheel surface cannot effectively contact the workpiece. In addition, if the roundness of the grinding wheel is lost and unevenness occurs, vibration may occur and even noise may be generated.

- The size is not refined: the loss of dimensional accuracy means that the grinding wheel loses its cutting force to a very serious extent and needs to be dressing immediately.

- Scratches or abnormal grinding lines on the surface of the workpiece: If the surface of the workpiece is scratched, it means that the self-sharpening ability of the grinding wheel begins to decrease, and the abnormality of the grinding line usually indicates that the performance of the grinding wheel begins to have problems.

When the above situation occurs, it is time to trim the grinding wheel. If it is ignored, it will cause great damage to the workpiece and will affect the efficiency of the entire process.

The best condition is to dressing the wheel as soon as the above conditions occur, in order to keep the workpiece in good condition. Of course, it is not possible to dress the grinding wheel all day long, because there will still be some related costs in the process of dressing, which is also a part that we need to pay attention to when dressing the grinding wheel.