The Fourth Third Generation Semiconductor Industry Development Summit is divided into two sections: silicon carbide and gallium nitride.

The morning half of 5.17 mainly focuses on silicon carbide SiC :

It mainly covers SiC material characteristics and applications, analyzes SiC single crystal growth technology, SiC power device applications, development of semiconductor epitaxial wafers, and mass production solutions, etc.

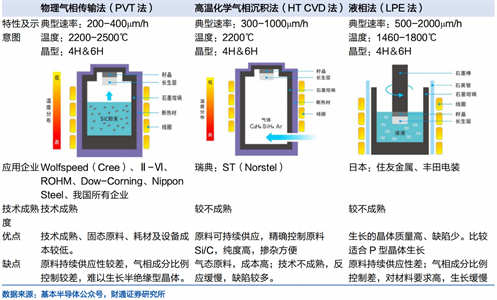

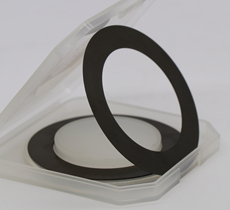

Physical Vapor Transfer method is the most common method to prepare SiC substrates. The current SiC crystal growth includes physical vapor phase transport (PVT), high-temperature chemical vapor deposition (HT-CVD), and liquid phase (LPE) methods.

The advantages of SIC in high temperature, high voltage, high current and high frequency applications, whether in terms of breakdown electric field, forbidden band width, electron saturation rate and thermal conductivity are much higher than those of silicon, which, together with its low losses, determine the wide application of silicon carbide in RF devices and power devices. Among them, SiC power devices account for the main market applications.

There are three main types of RF device materials: GaAs, Si-based LDMOS and GaN. The commonly used SIC materials in RF device applications are mostly semi-insulated silicon carbide substrates. Semi-insulated silicon carbide substrates for GaN RF devices are mainly used for power amplifiers for communication base stations and radar applications.

SIC Silicon Carbide Power Devices

Silicon carbide power devices have the unique advantages of high voltage, high current, high temperature, high frequency, high current, high temperature, high frequency, low loss, etc. It will greatly improve the energy conversion efficiency of the existing use of silicon-based power devices, which will have a significant and far-reaching impact on the field of efficient energy conversion, the main application areas are electric vehicles/charging piles, photovoltaic new energy, rail transportation, smart grid, etc.

Comparison of three types of semiconductor materials such as SiC, GaN and Si power devices and their market share:

SiC Application-New Energy Vehicle

New energy vehicles will become the largest market for SiC. The devices that need to use SiC devices in electric vehicles: DC/AC main inverter, car air conditioner, OBC car charger, battery charger, motor driver, DC/DC converter, etc. SiC devices can reduce the power lost by the motor control system of pure electric vehicles and hybrid vehicles to 1/10 and realize low power consumption; at the same time, it can increase the efficiency of new energy vehicles by 10%. Power devices produced using the SiC process have lower on-resistance, smaller chip size, higher operating frequency, and can withstand higher ambient temperatures. Among them, SiC SBD and SiC MOSFET devices are mainly used in OBC and DC/DC, and SiC MOSFETs are mainly used in electric drive.

Tesla Model 3~ models use ST's SiC MOSFET modules to significantly improve annual vehicle range and performance.

In 2020, BYD's high-end model "Han" is equipped with SiC devices; it is expected that by 2023, BYD will realize the full replacement of SiC devices to silicon-based IGBT devices in its electric vehicles, improving the performance of the whole vehicle by 10% on top of the existing one.

* Compared with silicon-based devices, the inverter output power can be increased to 2.5 times, the volume can be reduced by 1.5 times, and the power density can be 3.6 times.

* Taking the 22kW bi-directional OBC as an example, the cost of the SiC system is reduced by 15% compared to Si; at the same time, the energy density is 1.5 times higher than that of the Si system, and the unit cost can be reduced by about $40 per year by reducing energy consumption.

The SiC-based power device is a revolutionary innovation for hydrogen vehicle fuel cell DC/DC converters. To be able to adapt to the use of the original 400v DC fast charger, new vehicles with 800v voltage platforms must be equipped with additional DCDC converters for boosting, further increasing the demand for DCDCs.

Compared with traditional IGBT-based module converters, SiC-based power devices have more than 4 times higher switching frequency and 3 times higher power density, with an average system efficiency of more than 97% and a maximum efficiency of 99%.

In new energy vehicles, SiC-based power devices have cost advantages and will still occupy a certain market share and co-exist with wide-band semiconductor devices in the long run. In the future, silicon-based IGBT modules and SiC modules will also become the main form of application in new energy vehicle semiconductors. Compared with silicon-based devices, the balance between high process, high performance and cost of SiC power semiconductors will become the key core point for the real large-scale implementation of SiC power devices.

According to the Yole report, the market size of SiC power devices is USD 1.1 billion in 2021, and is expected to grow to USD 6.3 billion in 2027, with a CAGR of about 34%, driven by market demand for electric vehicles/charging piles, PV new energy, etc. The electric vehicle (inverter + OBC + DC/DC converter) is the largest downstream application of SiC, accounting for 62.8% to 79.2% of the market share continues to increase. The high performance ceiling of SiC material is highly suitable for new energy vehicles; and the rapid development of new energy vehicle market will drive the rapid growth of SiC market. With the demand for domestic substitution and policy stimulation, we expect domestic SiC companies to take up the heavy responsibility of meeting the market demand and welcome the coming of the SiC "on board" era.

Silicon Carbide Applications - Pan-New Energy

Photovoltaic and Energy Storage

Photovoltaic energy storage is the second largest market for SiC power devices, with a global market size of $150 million in 2021 and expected to increase to $460 million by 2027, with a CAGR of 20.0% from 2021-27. Conventional Si inverters account for about 10% of the cost in PV power generation, but are a major source of system energy loss. The use of SiC devices in PV inverters can reduce energy losses by more than 50%, increase energy conversion efficiency from 96% to 99%, and increase equipment cycle life by 50 times and reduce equipment size.

According to SolarPower Europe, under the neutral expectation, the global new PV installation will grow from 168GW in 2021 to 346GW in 2026 with 15.6% CAGR, and the market penetration of SiC devices in PV inverters will increase to about 50% in the same year. The market share of third-generation chips will continue to expand with the increase in installed capacity and penetration rate.

Charging Pile: Charging pile is developing towards high power, and the penetration rate of SiC devices will further increase.

Silicon carbide MOSFETs are broadband high-speed devices that enable high-voltage, high-current high-speed switching, thus revolutionizing the implementation of related applications, of which DC charging piles are one, and silicon carbide has further promoted the development of DC charging piles. Although the cost of silicon carbide is high compared to traditional silicon devices, it is able to reduce the system cost of charging piles in the application of charging piles due to the increased power density. With the increase in demand for supercharging and fast charging, all-SiC modules have started to be adopted in large numbers in charging piles. According to the parameters on the companies' websites, most of the high-performance charging piles with 800V architecture use all-SiC modules. Therefore, silicon carbide power devices, which can provide high power density and high temperature resistance, naturally become the best choice for electric vehicle charging piles.

Typical applications for SiC diodes: automotive, industrial energy, consumer:

With fast switching speeds and high voltage tolerance, SiC diodes are suitable for dry high frequency and high temperature applications such as power supplies and RF circuits. In addition, SiC diodes have the advantages of low reverse leakage current and low switching capacitance, which improve system efficiency and reduce energy waste. Silicon carbide diodes have excellent performance in extreme environments such as high power, high frequency and high temperature, so they can be used in many fields, such as power supply circuits, electric vehicles, solar inverters, LED lighting, etc.

The above is for this Shenzhen International Semiconductor Summit Forum SiC special learning and expansion, Moresuperhard will continue to learn to provide you with more industry information and semiconductor industry "cutting and grinding throwing", the follow-up will be for GaN special summary and sharing.

.jpg)