High precision rotary dresser factory

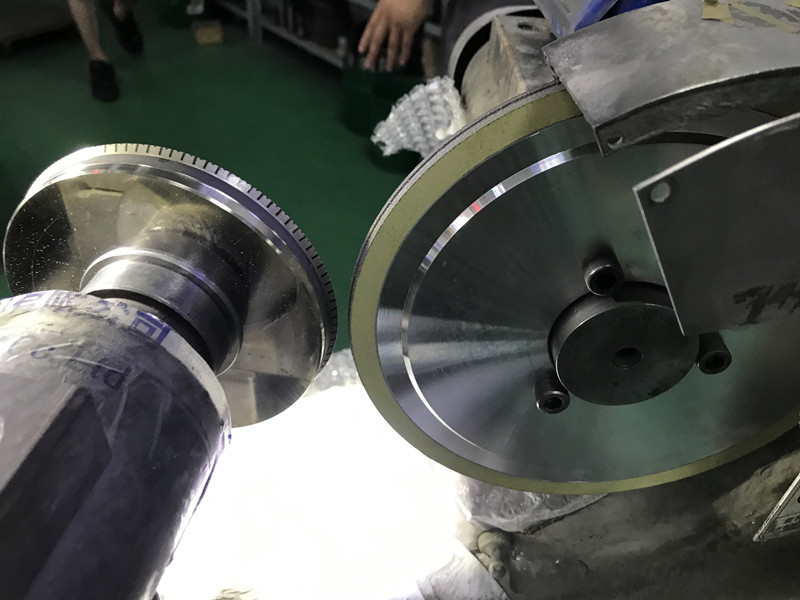

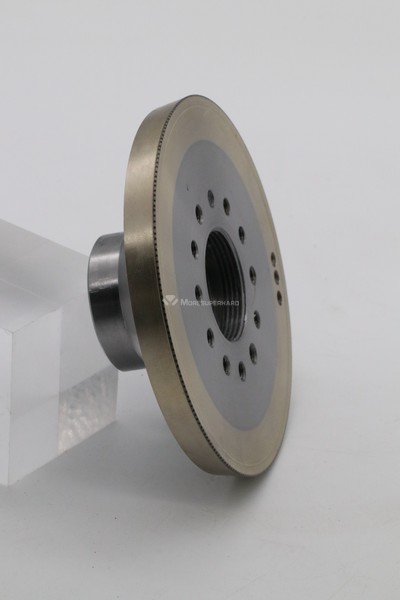

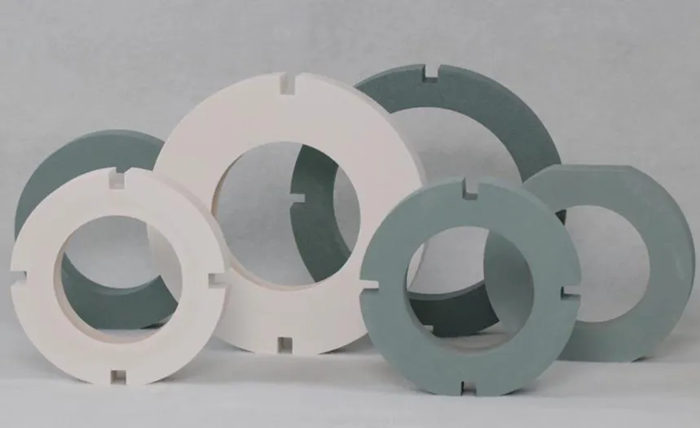

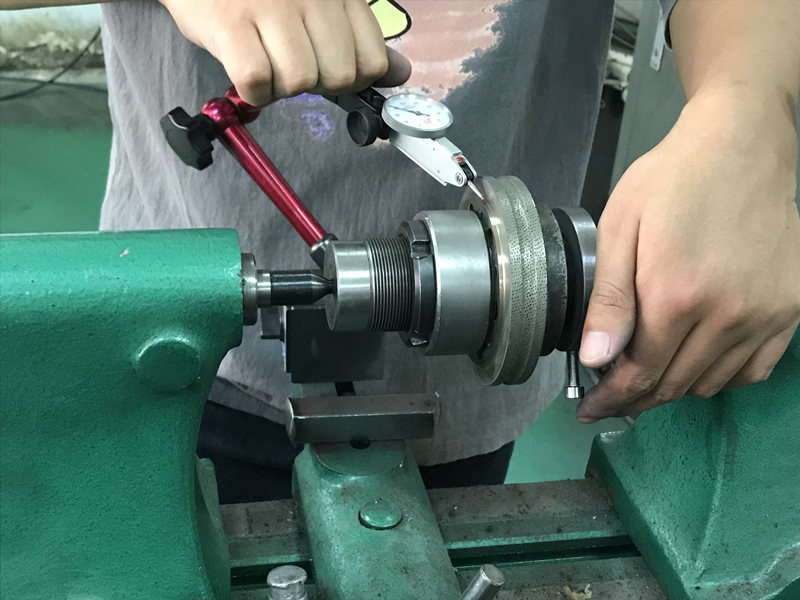

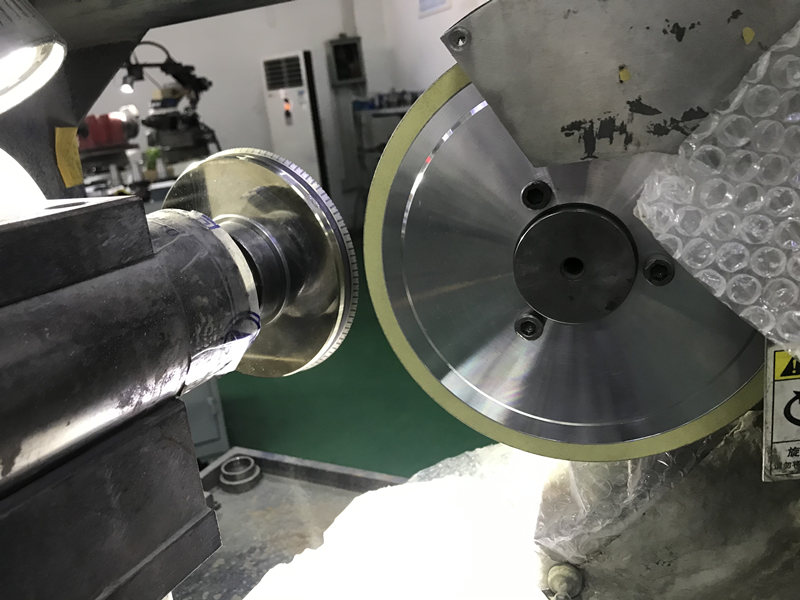

High precision rotary dresser and form dressing roll. Used for dressing grinding wheel (vitrified cbn wheel, SG grinding wheel) on Automotive industry and Gear industry.

Why should I dressing the grinding wheel use high precision rotary dresser?

During the grinding process, the state of the grinding wheel directly affects the grinding result. The state of the grinding wheel is like the change of the cutting force and the change of the shape of the grinding wheel. These changes will affect the yield and reproducibility of the finished product.

In general, the most common change is that the grinding wheel “cannot move”, meaning that the grinding wheel loses cutting force; the main reason for the grinding wheel to lose cutting force is two.

The first type is that during the grinding and extrusion process, the edges and corners are gradually rounded, which we call “passivation”. At this time, the self-sharpening ability of the grinding wheel does not function properly, which causes the cutting force to be lowered, and the grinding effect cannot be effectively exerted.

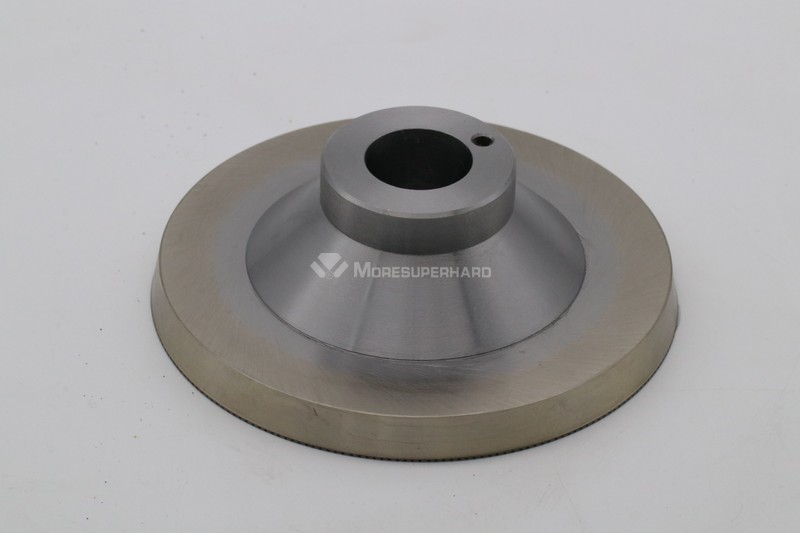

Rotary Diamond Dressers and Form Rolls moresuperhard offers High Precision Rotary Diamond dressers and Form Rolls to shape grinding wheels at shortest possible time. These dressers are offered profiling the simplest work piece to the most complicated shape with required precision demands.