What is cylindrical grinding machine?

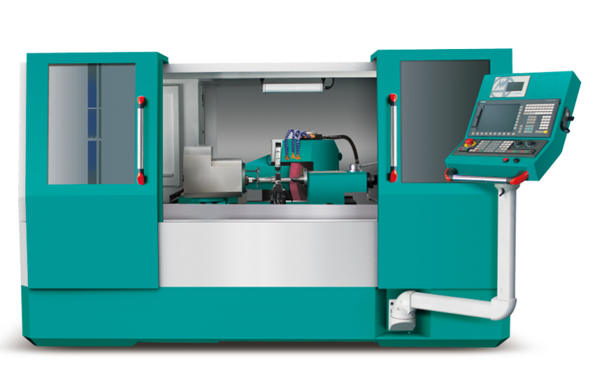

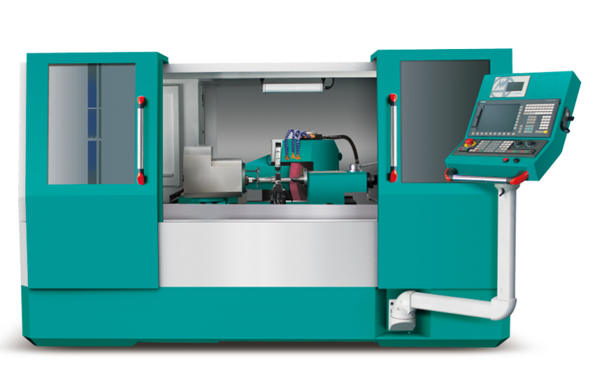

Cylindrical grinding machine is one of the most common machine tool series products in the field of machining, and it is generally used for processing various cylindrical, conical outer surfaces, as well as shaft shoulder end faces. From the product classification level, it can be divided into ordinary cylindrical grinding machine, universal cylindrical grinding machine, wide grinding wheel external grinding machine, end face external grinding machine, multi-wheel frame external grinding machine, multi-disc grinding wheel external grinding machine, cut type external grinding machine and special external grinding machine and other types.

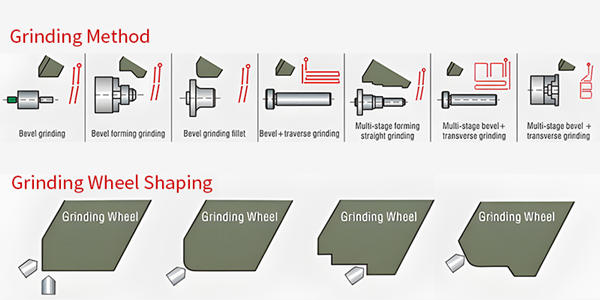

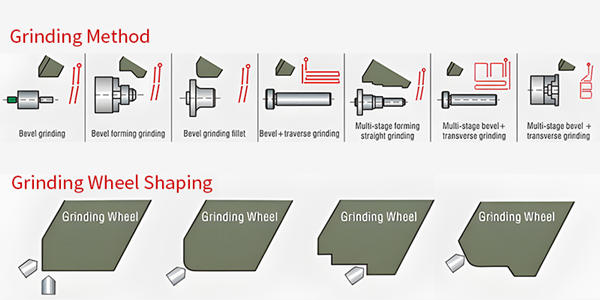

External cylindrical grinding machine is mainly used to grind external cylindrical and conical surface, there are two basic grinding methods: longitudinal grinding method and cut grinding method.

How does cylindrical grinding machine work?

How does cylindrical grinding machine work?

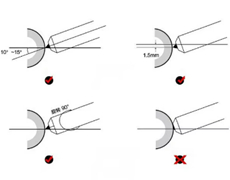

Longitudinal grinding: grinding wheel rotation for the main movement (nt), the feed movement has: workpiece rotation for circular feed movement (nω), the workpiece along its axis reciprocating movement for longitudinal feed movement (fα), in each longitudinal stroke or reciprocating stroke of the workpiece at the end of the grinding wheel cycle for a transverse feed movement (fr), all the surplus in multiple reciprocating stroke gradually grinding away.

When cutting in grinding: the workpiece is only circular feed (nω), without longitudinal feed movement, the grinding wheel is continuously transverse feed movement (fr), until all the grinding margin reaches the required size. On some cylindrical grinding machines, the step surface of the workpiece can also be ground with the end grinding wheel (see Figure c). During grinding, the workpiece rotates (nω) and moves slowly along the coaxial axis (fα) to complete the feed movement.

What are the applications of cylindrical grinding machins?

Cylindrical grinding machine is mainly used for precision grinding of end face, cylindrical and conical surface of batch shaft parts, which is the main equipment in automobile engine and other industries. It can also be applied to aerospace, textile spinning, manufacturing, office communication, equipment processing, food industry, pharmaceutical industry and many other industrial fields.

Daily maintenance methods of CNC cylindrical grinder:

1.After daily work, use a brush to clean the entire body with the outer grinder. It is prohibited to use an air gun to blow air directly on the workbench or guide rail to prevent iron filings from entering the guide rail and affecting the accuracy of the cylindrical grinder.

2.During operation, it is strictly forbidden to use a fan to blow air against the workbench to prevent dust and iron filings from rolling into the guide rails and affecting the accuracy and feel of the guide rails.

3.Cylindrical grinder guide rail oil should be replaced and replenished in time. Under normal circumstances, if the oil in the oil sight glass becomes cloudy or black, it should be replaced. The time is controlled within 3-6 months, the first 3 months and the last 6 months

4.Please use professional lubricating oil for the guide rail of the cylindrical grinder. Generally, 32× guide rail oil is used.

5.Regularly check whether the wire rope of the cylindrical grinder workbench is loose and locked to prevent it from breaking or affecting the accuracy of the hand.

6.Clean the workbench guide rails regularly to prevent iron filings from wearing away the surface of the guide rails and affecting the accuracy of the guide rails. Clean the rails with gasoline and wipe them with a rag. For debris embedded in the wear-resistant plate, gently remove it with a blade. The above operations should be performed under the guidance of professionals or handled by the person in charge of the cylindrical grinder manufacturer.

7.Regularly check whether the cylindrical grinder body is running stably and level.

8.If it is a manual cylindrical grinder, check the tightness of the wire rope regularly

9.If it is a semi-automatic cylindrical grinder, check the grinding fluid concentration every week and replace it in time.

---EDITOR: Alan Wang,Jackie Wang

---POST: Jackie Wang