Introduction of Advanced Grinding & Machining Solutions for Aero-Engine and Gas Turbine Components

As a leading provider of grinding and machining solutions, we specialize in addressing the complex manufacturing challenges of the aerospace and energy sectors. Our advanced technologies support the production of critical components such as compressor blades, turbine discs, rotor systems, and combustion chambers with unparalleled precision and efficiency.

Key Application Areas

-

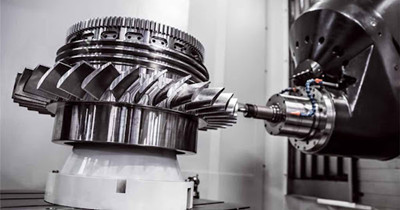

Blade Machining: Five-axis milling and precision grinding of turbine/compressor blades and roots.

-

Disc & Rotor Processing: Heavy-duty turning, slot broaching, and high-speed grinding of turbine and compressor discs.

-

Casing & Combustion Systems: Deep-hole drilling, boring, and milling of engine casings and combustors.

-

Tooling & Coatings: Custom CBN/form grinding wheels, TiSiN/TiAlN-coated tools, and ultrasonic-assisted cutting systems.

Technological Highlights

-

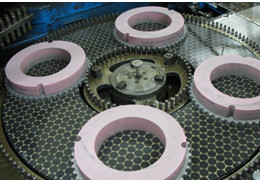

CBN/Form Grinding Wheels: Enable burr-free, high-temperature alloy grinding for blades and disc serrations.

.jpg)

-

Ultrasonic-Assisted Machining: Reduces cutting force and improves surface quality in titanium and superalloy components.

-

High-Efficiency Drilling: Micro-drills with AlTiCrN coatings extend tool life, boosting hole-making efficiency by 50%.

-

Automated Grinding Systems: Integrated CNC grinding and robotic loading for mass production of blades, seals, and rings.

Why Partner With Us?

-

Tailored solutions for titanium, nickel-based alloys, and ceramic composites.

-

Proven expertise in aerospace manufacturing standards and R&D collaboration.

-

End-to-end support from process design to tooling optimization.

Elevate your aero-engine and gas turbine manufacturing capabilities with our precision grinding and machining systems. Contact us to request a technical consultation or schedule an on-site demonstration.

Email: [email protected]

Whatsapp: +8619900915906

.jpg)