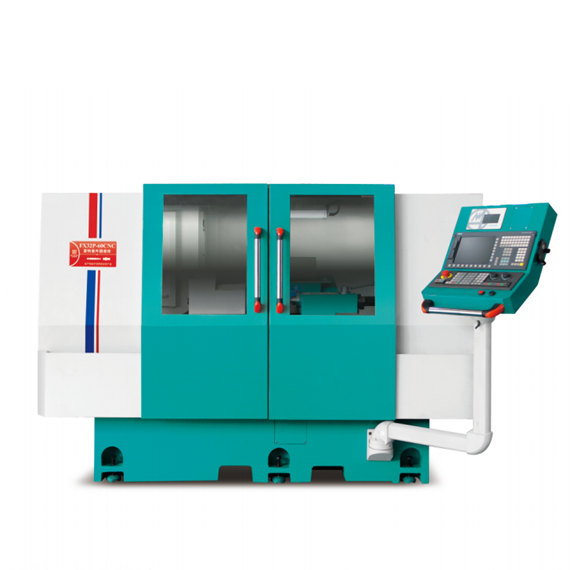

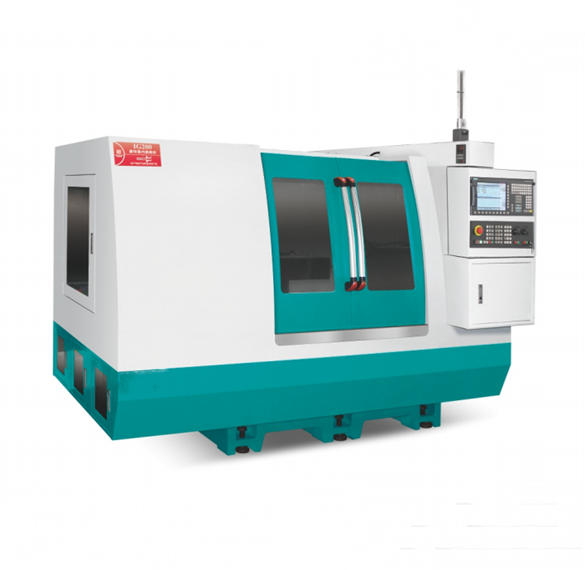

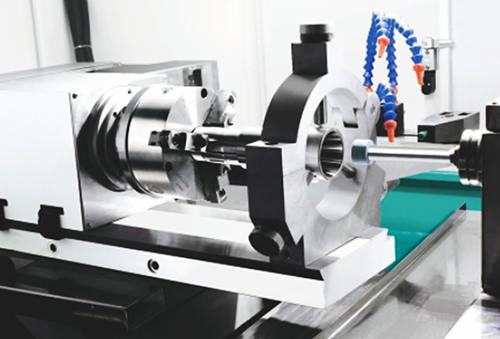

Our universal internal cylindrical grinding machines are designed to solve almost anything you need: Flange parts, spindle shafts, spindle housings, rotor shafts, bushes and much more for the areas of machine tools, drive elements, aerospace and others.

1. FANUC Operating System

1. FANUC Operating System

►Fully automatic cycle grinding, coarse grinding, dressing, fine grinding, non-spark grinding.

►Flexible control, increased functions, and easy changes.

►Abnormal history records, troubleshooting instructions, improve the efficiency and quality of after-sales service.

►Digitized grinding, improved precision, established standardization, and ensured stable and consistent product quality.

2. Grinding Data

| Inner diameter grinding range |

Φ6-200mm |

| Grinding maximum hole depth |

170mm |

| The maximum travel of the table |

>500mm |

| Grinding wheel spindle speed |

0-32000rpm |

| The minimum resolution of X/Z axis feed |

0.001mm |

| The clamping length of the extended workbench and the center frame can reach |

800mm |

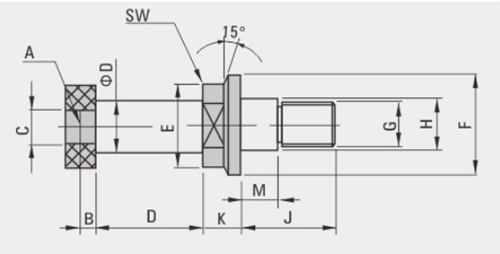

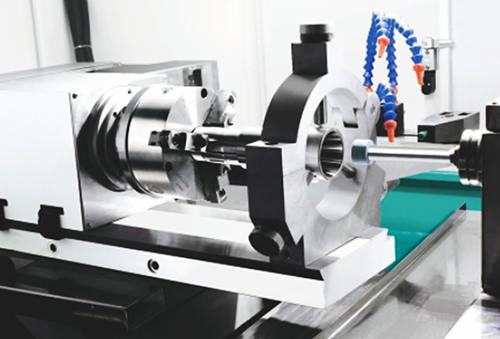

3. Grinding Machine Bed Structure

.jpg)

►High rigidity support

The high rigidity design of the bed, grinding wheel frame, workpiece head frame, feed mechanism, etc., provides process guarantee for the inner hole grinding of large size, excess and high hardness products

►Efficient

Different grinding spindles are selected to adapt to the grinding of products with different apertures. In addition to diamond pens, roller dressing is also provided for dressing. Ceramic CBN grinding wheels can be used for efficient grinding, and Marposs inner diameter gauges can be used for online inner diameter measurement.

►High stability

The key parts of the machine tool are selected from top international brands to ensure the reliability and precision stability of the machine tool during its life cycle.

►High convenience

Graphical software design allows the operator to input parameters through a user-friendly interface, so as to quickly generate workpiece grinding, grinding wheel dressing, online measurement and other related programs

►High safety

Fully enclosed machine tool shield and high-grade tempered glass observation window, emergency stop, one-button return, safety door interlock and other designs provide safety guarantee for operators.

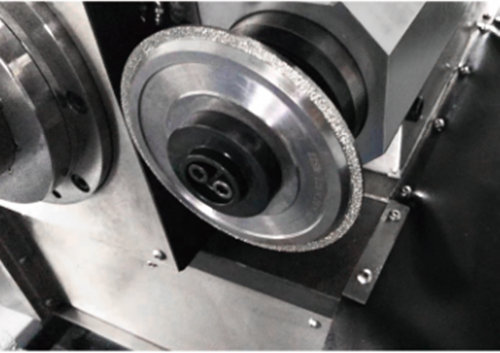

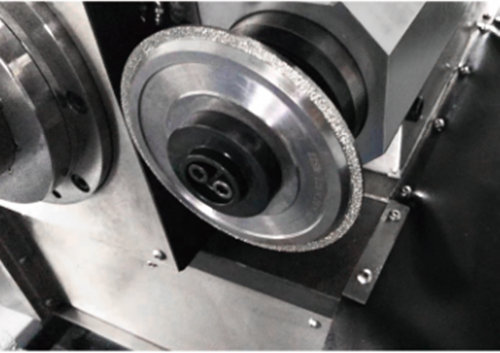

4. Diamond Rotary Dresser System

Dressing mode:CNC automatic correction dressing

►When using diamond or CBN grinding wheel, you can choose the dressing mode without correction

►When facing difficult-to-grind workpieces, multiple correction and dressing modes can be selected to ensure the best quality.

5. Optional Accessories

Online Measuring Device

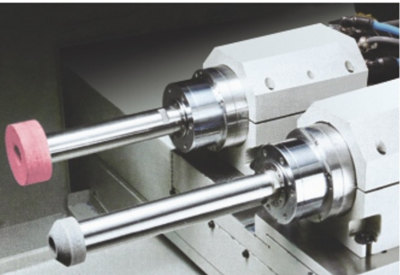

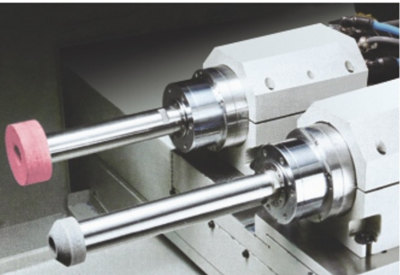

Dual grinding Spindle

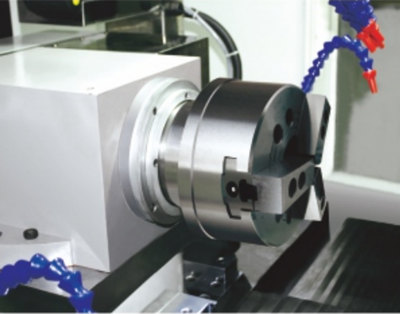

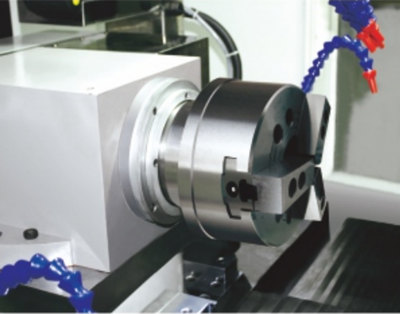

Hydraulic Three-jaw Chuck

.jpg)