Double-disc grinding machines are high-efficiency equipment designed for simultaneously grinding two parallel surfaces of workpieces. Available in horizontal and vertical configurations with through-feed, rotary-table, or reciprocating feeding systems, these machines have evolved significantly since their introduction in China in the 1950s. Today, CNC-enabled models are widely used in automotive, bearing, and electronics industries for processing critical components like piston rings, bearing rings, and magnetic sheets.

Technical Highlights

-

Precision Engineering: Crossed roller guides and CNC systems ensure grinding head feed accuracy of 0.005mm.

-

Ultra-Flat Surfaces: With CBN grinding wheels, achieve parallelism ≤0.005mm and flatness ≤0.003mm.

-

High Efficiency: Automated vertical models support continuous production of over 70,000 parts per shift.

-

Adaptability: Process workpieces with thicknesses of 0.4-40mm and diameters of φ12-150mm (e.g., Yuhuan CNC YH2M84120 model).

Key Applications

-

Automotive: Piston pins, rings, valve washers, connecting rods, cross shafts, rotors, and hydraulic pump blades.

-

Bearings: Inner/outer rings and rollers.

-

Electronics: Magnetic rings, graphite plates, and alloy sheets.

Grinding Wheel Innovation

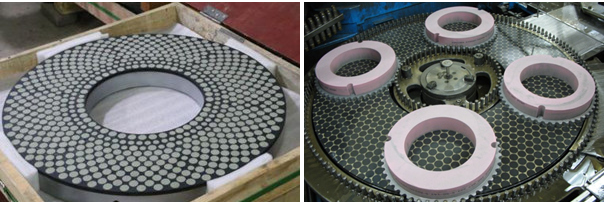

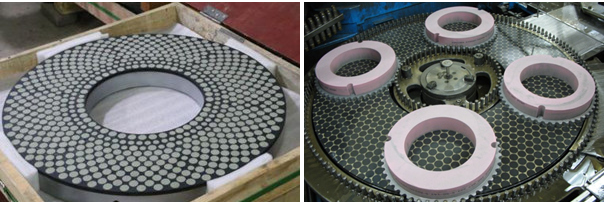

Double-disc grinding machines paired with CBN or diamond grinding segments (hexagonal/circular shapes, 5-10mm thickness) offer enhanced durability and precision. Hexagonal segments provide denser grinding surfaces for superior finishes but at a higher cost.

Why Choose More Superhard Double-Disc Grinding Machine?

(1).jpg)

-

Precision: Ideal for micron-level tolerance requirements.

-

Productivity: Automated loading/unloading systems enable mass production.

-

Versatility: Compatible with ferrous, non-ferrous, and composite materials.

(1).jpg)