The grinding process is the grinding wheel surface of the abrasive particles on the surface of the workpiece cutting, grooving and sliding rubbing of the integrated action of the process

Cylindrical grinding:

Cylindrical grinding can be carried out on ordinary cylindrical grinder or universal cylindrical grinder or centerless grinder, usually as a finishing process after semi-finishing turning.

1. Longitudinal grinding method

When grinding, the workpiece makes a circumferential feeding movement, and at the same time makes a longitudinal feeding movement with the table, so that the grinding wheel can grind all the surfaces. At the end of each longitudinal stroke or reciprocating stroke, the grinding wheel makes a transverse feed, and the grinding allowance is gradually ground away to grind a very long surface with good grinding quality. Especially in single piece, small batch production and fine grinding, generally used longitudinal grinding method.

2. Traverse grinding method (plunge-cut grinding method)

With the transverse grinding method, there is no longitudinal feed movement of the workpiece. A grinding wheel wider than the surface to be ground (or as wide as the grinding surface) is used to feed the workpiece transversely at a very slow feed rate until all the machining allowance is ground. The horizontal grinding method is mainly used for grinding the short length of the cylindrical surface and both sides of the step of the surface.

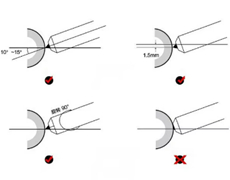

3. Deep grinding method

Characterized by all the grinding allowance (generally 0.20m in diameter) in a longitudinal tool grinding. The workpiece circumferential feed rate and the longitudinal feed rate are both very slow when grinding, and the front end of the grinding wheel is trimmed to a stepped or tapered shape. The productivity of the deep grinding method is approximately twice as high as the longitudinal grinding method, and can reach grade IT6 with a surface roughness of Ra values between 0.4 and 0.8. However, the dressing wheel is more complex, only suitable for large quantities, mass production, grinding allows the wheel to cross out of the machined surface at both ends of a greater distance from the workpiece.

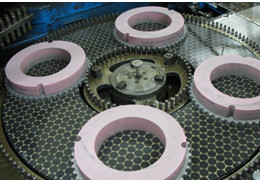

4. Centerless cylindrical grinding method

The workpiece is placed between the grinding wheel and the guide wheel, with a pallet below. Grinding wheel (also known as the work wheel) turn to play a cutting role, the guide wheel is a very fine-grained rubber bond grinding wheel. The friction between the workpiece and the guide wheel is high, which causes the workpiece to rotate at a linear speed close to that of the guide wheel. Centerless cylindrical grinding is performed on centerless cylindrical grinding machines. Centerless cylindrical grinding machine productivity is very high, but the adjustment is complex; can not be corrected set of parts hole and cylindrical coaxiality error; can not be ground with a longer axial groove parts in order to prevent a larger roundness error in the outer circle. Therefore, centerless cylindrical grinding is mostly used for long and thin shafts, pins and small sets of parts such as large quantities, mass production of shaft diameter.

Internal Grinding:

Internal cylindrical grinding in addition to ordinary internal cylindrical grinding machine or universal cylindrical grinding machine, for large thin-walled parts, can also be used centerless internal cylindrical grinding in addition to ordinary internal cylindrical grinding machine or universal cylindrical grinding machine, cylindrical grinding; for the weight of large, asymmetric shape of the parts, can be used planetary internal cylindrical grinding, this time, the outer circle of the workpiece should be the first through the finishing process of internal cylindrical grinding due to the poor rigidity of the grinding wheel axis, are generally used in the longitudinal grinding method. Only in the special case where the hole diameter is large and the grinding length is short, internal grinding adopts the transverse grinding method.

Compared with external grinding, internal grinding has the following characteristics.

1. grinding internal circle, by the limitations of the workpiece hole diameter, can only use a smaller diameter grinding wheel. Internal grinding wheel needs frequent dressing and replacement, but also reduces productivity.

2. The grinding wheel linear speed is low, the surface of the workpiece can not be polished, and limits the amount of feed, so that the grinding productivity is reduced.

3. In internal grinding, the grinding wheel axis is thin and long, with poor rigidity and easy to vibrate. Therefore, only a very small amount of cutting can be used, which not only reduces the productivity, but also makes the quality of the ground hole is not high.

4. Internal grinding wheel and workpiece contact area is large, more heat, and cutting fluid is difficult to pour directly into the grinding area, so the grinding temperature is high.

Surface Grinding

Various positions on the parts of the plane, such as parallel to each other's plane, perpendicular to each other's plane and tilted to a certain angle of the plane (machine tool guide surfaces, V-shaped surfaces, etc.), are processed by grinding. The Ra value of the surface roughness of the ground plane is between 0.20.8, the dimensions are up to IT5-IT6, and the parallelism to the base surface is up to 0.005-0.01mm/ 500mm.

Peripheral grinding is characterized by small contact surface between grinding wheel and workpiece, small grinding force, good chip removal and cooling conditions, small thermal deformation of the workpiece, and uniform wear of the grinding wheel, so the workpiece is processed with high precision. However, the grinding wheel spindle works cantilevered, limiting the choice of grinding dosage productivity is low. Face grinding is characterized by a large contact surface between the grinding wheel and the workpiece, axial force on the spindle, and better rigidity, so it allows the use of larger grinding dosage and higher productivity. However, the grinding force of endface grinding is large, heat generation is large, chip removal and cooling conditions are poorer thermal deformation of the workpiece is large, and the grinding wheel wear is not uniform, so the machining accuracy of the workpiece is low.

---EDITOR: Elio Song,Jackie Wang

---POST: Jackie Wang