Customer Case: Application of CBN Ceramic Bond Grinding Wheels in the machining of convex molds

Case Background

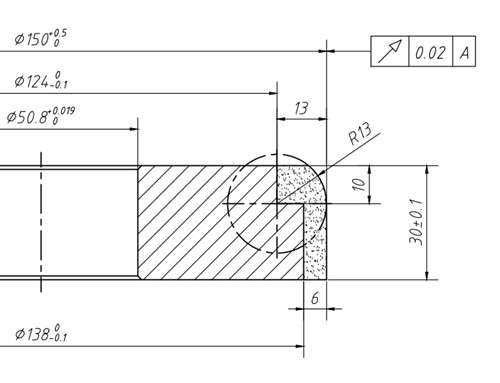

Our customer is engaged in precision machining of high hardness convex molds, using ANCA TX7+ CNC grinder for machining large diameter tools. The workpieces are made of high hardness HSS, SKD11, SKH51 steel, with a hardness range of HRC 61-67, and a surface roughness of Ra 0.2 is required. Customers have high requirements for grinding accuracy, surface finish and grinding wheel wear resistance.

Recommended products:

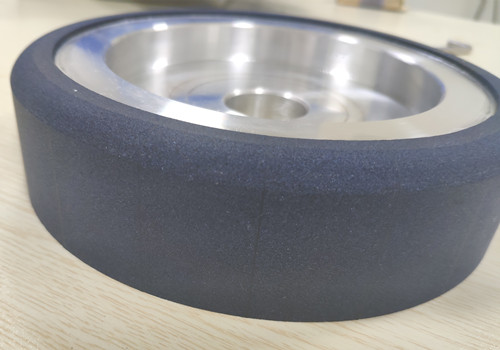

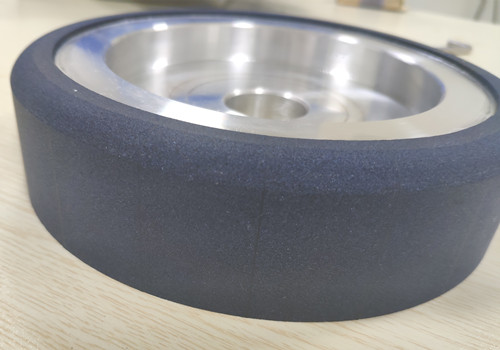

CBN ceramic bond grinding wheels

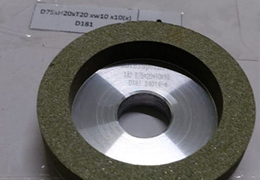

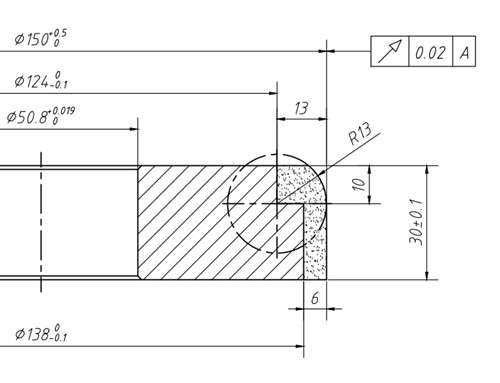

In response to the customer's needs, we recommend the use of CBN ceramic bond grinding wheels, specific models and specifications are as follows:

Model:

1Q1-D:150-T:30-W:13-X:6-R:13

Binding agent: Ceramic bond

Equipment:

ANCA TX7+ Heavy Duty CNC Grinder

Designed for efficient precision grinding of high hard materials, this wheel is especially suitable for use on ANCA TX7+ grinding machines. Its ceramic bond has excellent thermal stability, which maintains good wear resistance and grinding efficiency in high hardness grinding, and meets the customer's requirements for grinding accuracy and surface finish.

Process and Performance

During the machining process, the customer removes 0.2mm of grinding allowance from the convex die and dresses every 20 pieces. The test results show that the CBN ceramic bond grinding wheels are able to maintain the required surface roughness (Ra 0.2) stably when grinding cam dies made of HSS, SKD11, and SKH51 materials, and demonstrate highly efficient grinding capability and durability. The ceramic bond properties of the grinding wheel make it less prone to chipping in a high hardness grinding environment, ensuring high precision machining results.

Customer Feedback

Customers have commented that the use of our recommended CBN ceramic bond grinding wheels has resulted in a significant increase in grinding efficiency to meet the demands of precision machining. The customer especially appreciates the durability of the grinding wheel, which reduces the time and cost of frequent replacement. Due to the excellent performance of the grinding wheel, the customer has planned to use it as a long-term grinding solution for subsequent machining of high hardness workpieces.

Conclusion

This case demonstrates our technical capabilities in providing grinding solutions for high hardness materials. By customizing and recommending CBN ceramic bond grinding wheels, we solved the customer's high hardness grinding problems in cam die machining and achieved significant results in terms of grinding efficiency and accuracy. In the future, we will continue to dedicate ourselves to providing high-performance grinding solutions to bring better support to our customers' precision machining.