Are you looking for a reliable solution for processing ceramic seals with precision and efficiency? Look no further than our Vitrified Bond Diamond Double Disc Grinding Wheel, designed specifically to meet the rigorous demands of ceramic seal grinding.

Customer Case of Double End Grinding Disc for Ceramic Seal Processing

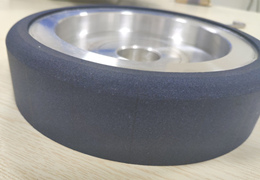

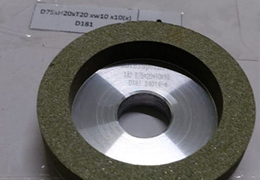

Grinding Wheel Type:

Vitrified Bond Diamond Double Disc Grinding Wheel

Size: D700xH320xT50xt7mm

Grit Size: 800#

Workpiece Material: High-quality Ceramic

Workpiece Name: Ceramic Seal

Surface Finish Requirement: Mirror Polish Ra0.15

Machine Compatibility: Compatible with Local Grinder Brands

Why Choose Our Double End Grinding Disc?

Precision Grinding for Ceramic Seals

Our vitrified bond diamond grinding wheel provides exceptional grinding performance for ceramic seals. Achieving a mirror polish with a surface finish of Ra0.15 is now easier than ever.

Durable and Efficient

Designed with vitrified bond technology, our grinding wheels offer outstanding durability and resistance to wear, ensuring consistent performance across multiple cycles.

High-Quality Finish

Achieve the perfect mirror finish every time. The 800# grit size ensures smooth, uniform surfaces, which is critical for parts like ceramic seals that require precision and high-quality finishes.

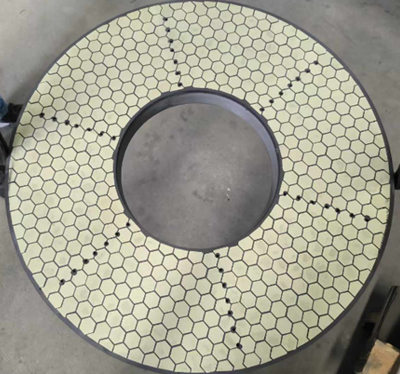

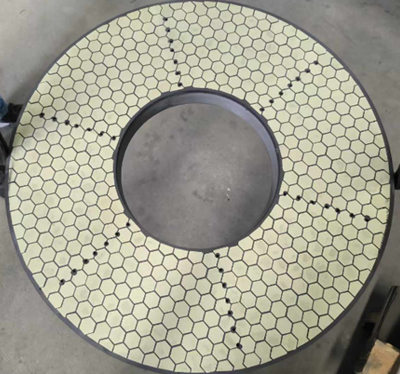

Optimized for Precision Machining

This double-disc design maximizes efficiency, allowing for precise and fast processing of ceramic seals while maintaining tight tolerances and high-quality results.

Versatile and Compatible

Whether you're using local grinder brands or specialized machines, our double-end grinding disc fits seamlessly into various grinding setups.

Moersuperhard Double End Grinding Machine:

_(1).jpg)

Boost Your Production with Our Advanced Grinding Solutions

Our Vitrified Bond Diamond Double Disc Grinding Wheel is engineered to meet the highest standards of surface finish and durability, making it the ideal choice for businesses looking to improve their manufacturing process for ceramic seals.

Ready to elevate your production quality? Contact us today to learn more about our precision grinding solutions and how we can help optimize your operations!

_(1).jpg)