The Background of Diamond Grinding Wheels Case

When sharpening carbide rotary saw blades on a Vollmer CHD 250 grinding machine, the customer needed a high-precision and high-efficiency sharpening tool. The saw blades are made of HSS (High Speed Steel) and have carbide teeth with a hardness of up to 85 HRC. In this context, we recommended diamond grinding wheels for sharpening carbide saw blades, which ensure excellent results in the sharpening of high hardness materials.

Recommended Process Specification with Diamond Grinding Wheels:

Recommended Process Specification with Diamond Grinding Wheels:

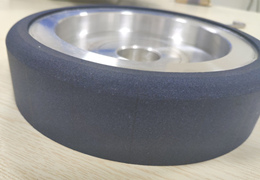

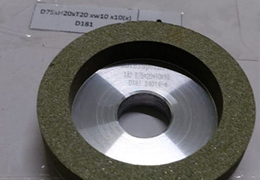

Diamond grinding wheel size: 14 F1 Ø200 x 4 x 6 x R2 x 60 H7 x T 6,5 x J 162 D181 C 75

Grinding wheel size: Ø200 x 4 x 6 x R2 x 60 H7 x T 6,5 x J 162

Diamond grit: D 181

Bond: C 75

Grinding machine: Vollmer CHD 250

Cooling: Oil cooled

Grinding wheel speed: 2500-3000 rpm

Machining process and performance

When sharpening carbide rotary saw blades with the recommended diamond grinding wheels, the customer successfully achieved a grinding depth of 0.1 mm and a surface roughness of 0.4 µm Ra, which is in line with the requirements for high-precision machining. By using our recommended diamond grinding wheels, the customer not only improved the grinding efficiency, but also obtained a higher quality surface, which significantly improved the durability and cutting performance of the product.

Customer Feedback

Customers have reported that the grinding process is smoother and more efficient with MORESUPERHARD diamond grinding wheels. The grinding wheels have exceeded expectations in grinding carbide saw blades, especially in maintaining high

precision and high surface quality. The customer was very satisfied with the durability and grinding performance of the grinding wheels and indicated that they will continue to use our products in their future production.

Conclusion of the Customer Case of Diamond Grinding Wheels for Sharpening Carbide Tipped Saw Blades

By providing our customer with customized diamond grinding wheels, we not only solved the grinding challenges in sharpening their carbide saw blades, but also helped them achieve higher productivity and better processing results. Our diamond grinding wheels have become the tool of choice for our customers due to their excellent hardness, wear resistance and machining accuracy. We will continue to strive to provide efficient and reliable grinding solutions to help our customers enhance their machining capabilities.