Case Background

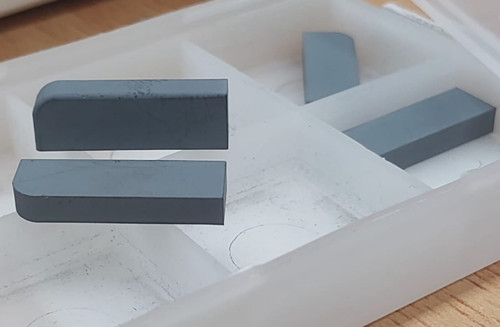

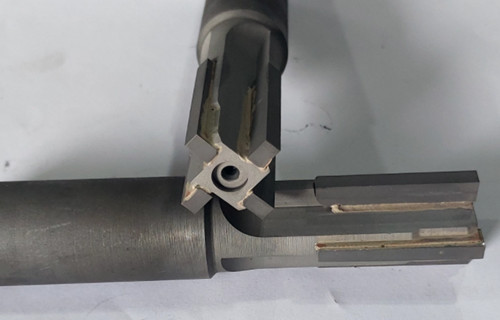

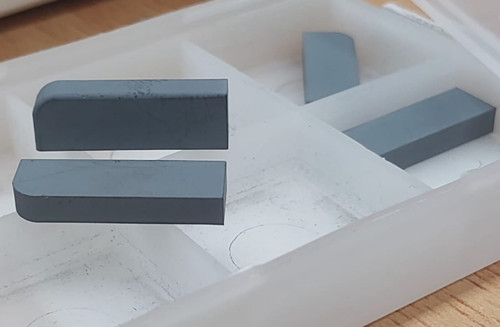

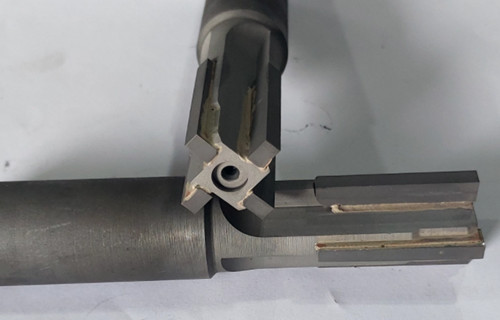

The customer specializes in the machining of Cermet tools and requires diamond grinding wheels for efficient grinding and high precision. The customer wanted to find a grinding tool for Cermet tools and needed a catalog of Cermet grinding wheels to choose from. In addition, the customer shared photos of diamond grinding wheels of WINTER, MGV and EHWA brands currently in use to help us understand the characteristics of the grinding tools they use.

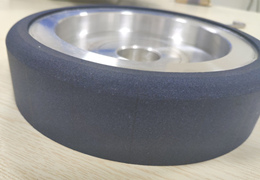

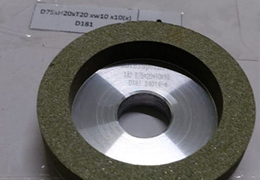

Recommended Product: Resin Bond Diamond Grinding Wheels

Recommended Product: Resin Bond Diamond Grinding Wheels

In response to the customer's needs, our technical team analyzed the situation and suggested the customer to try hybrid bond or resin bond diamond grinding wheels.

Specific models are recommended as follows:

Resin bond diamond grinding wheel

Model:

11V9 D100-H20-T35-X3-U10 V70° D64 C100

Application: Specialized for precision grinding of metal and ceramic tools.

Communication process and technical support

During the communication process with the customer, we understood the customer's grinding needs and tool characteristics in detail, and analyzed the existing brands of grinding wheels. Our technical team discussed with the customer about the grinding performance, bond formula and grinding efficiency, and finally suggested the customer to test the 11V9 resin bond diamond grinding wheel on the basis of their existing process.

After much consideration, the customer decided to accept the proposal and place an order for the

11V9 grinding wheel for testing.

Test results and customer feedback

Through the initial test, the customer feedback said that our recommended 11V9 resin bond diamond grinding wheel showed good wear resistance and stability in metal-ceramic tool machining. The grinding wheel shows smooth cutting effect during the grinding process and has a long service life, which significantly improves the production efficiency. The customer indicated that they will continue to use our products in subsequent orders.

Moresuperhard Conclusion

This case not only demonstrates our technical competence in grinding solutions, but also our responsiveness and professionalism in customer service. By providing our customer with detailed product analysis, testing support and customized technical solutions, we have successfully met their metal-ceramic tool grinding needs. In the future, we will continue to provide our customers with efficient, customized grinding solutions to help them improve machining quality and efficiency.