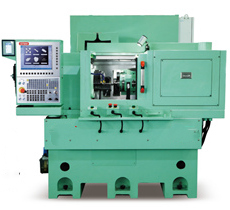

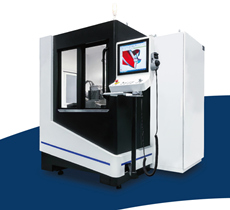

1.Intelligent grinding solutions

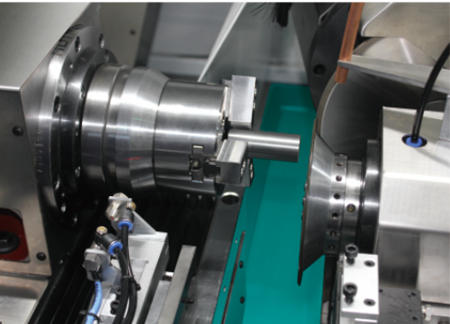

- The four-axis step grinding machine is equipped with a three-axis manipulator loading and unloading mechanism to realize batch processing of components.

- Online measurement system ensures accuracy is maintained during long periods of unattended operation

- The first centering type workpiece clamping configuration in China, which obtains superior concentricity in grinding.

- The roughing and finishing axes are effectively matched to obtain the best accuracy and surface finish by diameter difference compensation

- MSH self-developed control system and software, to achieve rapid creation of workpiece editing.

2. Automated manipulator/robot

2. Automated manipulator/robot

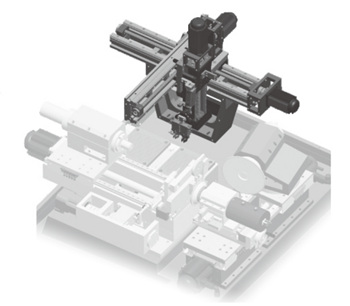

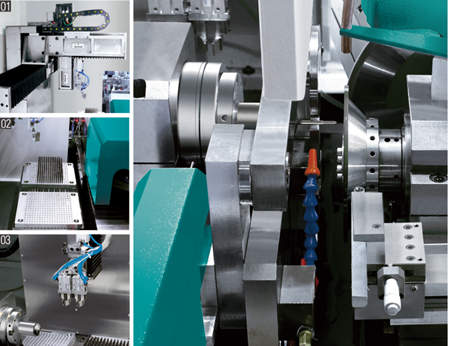

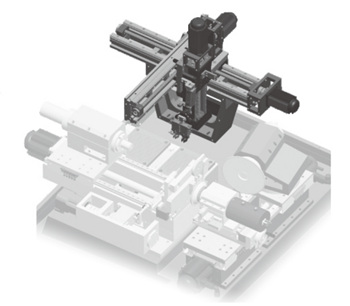

a. Manipulator automatic scheme

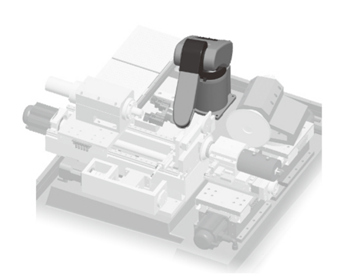

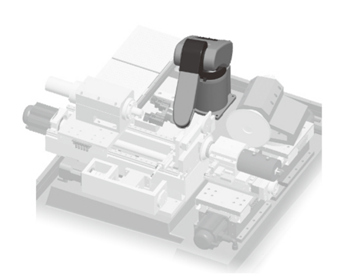

b. Robot automatic scheme

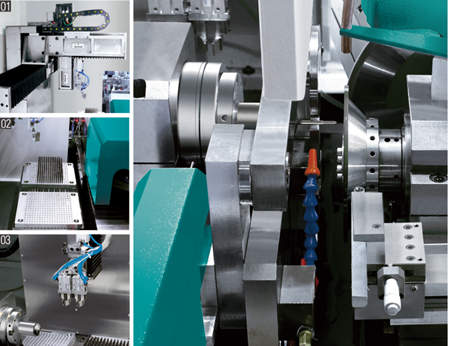

01. Robotic device

Automatic loading and unloading machinery manual power supply of 3 ANCA servo motors, through the combination of precision rail and ANCA control system, in the process of feeding and receiving materials, can be efficient, accurate and convenient to complete the entire feeding and receiving process

02. Tray device

Preparation tray and closing load of 340~510PCD Easy to operate, flexible, just pick up and align with four holes can be put back.

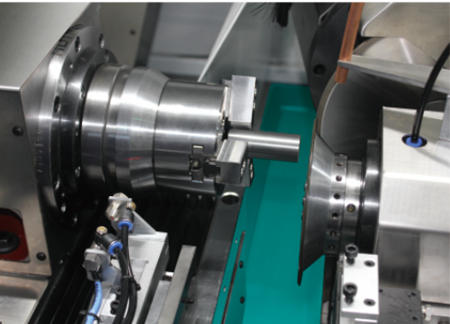

03. Loading and unloading device

Using two pneumatic finger cylinders, loading and unloading products. A rotating cylinder is used to adjust the Angle from 0 to 90°

3. Control system

a. Advanced interface module

Enable operators to seamlessly monitor and interact with the data being processed, providing a cutting-edge user experience

b. Full customization

Buttons and ICONS can be freely moved and rearranged to meet the business needs of different users.

c.19 inch digital LCD display Capacitive multi-G industrial touch screen, complete effective display area, waterproof and oil proof.

d. Quick job creation

.jpg)

The operator can create a new tool profile, in the case of a T-shaped knife, the tool profile is created by adding from left to right (as shown in the picture above) the far right side of the tool face. According to the desired knife type, click the knife type at the top of the screen to add from left to right, and the X on the far right is the delete button

.jpg)

e. After setting the shape and size of each section, you can easily complete the editing of the T-cutter, and set the spindle speed and feed speed at each grinding section.

4. Workpieces

.jpg)

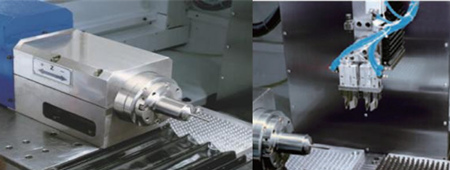

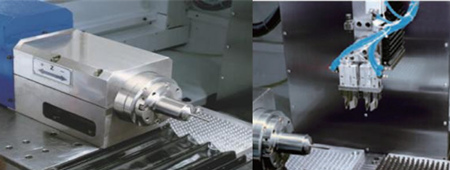

The standard clamping method of the machine itself is collet type, and the optional Swiss Schauberlin collet clamping is adopted, which has high clamping precision and good durability.

The automatic loading and unloading manipulator is powered by three servo motors. Through the combination of precision linear rails and precision control systems, the entire material delivery and receiving process can be completed efficiently, accurately and conveniently.

Using Italian Marposs contacts or Japanese Keyence laser positioning devices, the front positioning method can accurately process the multi-level step difference of the workpiece, ensure the step length size of the workpiece, and eliminate the error caused by the automatic feeding device and clamping.

Workpiece Grinding Process:

1. Workpiece Drawing: Determined by the Customer

2. Workpiece Material: Determined by the Customer

3. Workpiece Grinding Method:

4. Production Cycle:

Equipment Pre-acceptance:

1. Pre-acceptance Conditions:

(1) The Buyer shall provide the confirmed drawings, samples and test specifications of the grinding workpieces before signing the contract and technical agreement;

(2) The Seller shall be responsible for keeping confidential all technical information provided by the Buyer;

(3) The Seller shall notify the Buyer of the pre-acceptance time 10 days before the pre-acceptance, and the Buyer shall prepare 30 relevant workpieces and send them to the Seller or bring the workpieces to the Seller's factory for on-site acceptance according to the circumstances.

(4) The Seller shall make preparations for the pre-acceptance before the Buyer's personnel arrive at the equipment manufacturer.

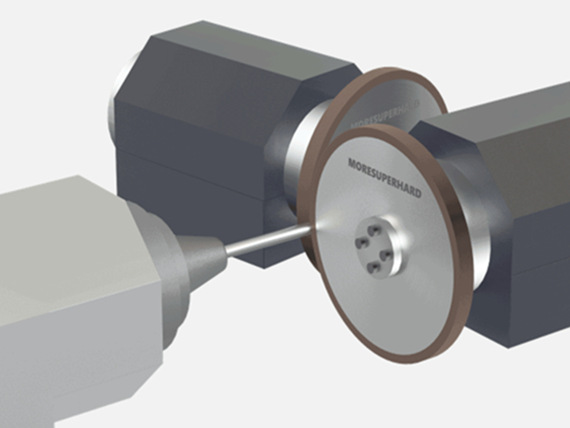

(5) The grinding wheel parameters shall be selected by the Seller according to the drawings provided by the Customer, and the relevant grinding wheels shall be configured after the contract is signed.

2. Pre-acceptance Content and Standards: The acceptance specifications agreed upon by the Buyer and the Seller shall be carried out in accordance with the drawing standards provided by the Buyer.

(1) Equipment Appearance Inspection

(2) The convenience of equipment operation and maintenance (based on the design of the Seller's machine tool equipment).

(3) The impact of equipment strength and rigidity on quality (based on the equipment accuracy inspection table provided by the Seller)

(4) The actual measurement record of equipment operation (empty and full load operation time, content, etc.).

(5) The actual measurement record of each major performance index of the equipment.

(6) The inspection record of major components and the inspection content of assembly records.

(7) Confirmation of important accessories.

(8) Continuously process 30 pieces of grindable products to meet the requirements of the drawings, and the equipment operates normally.

(9) The scrap products that the Seller is allowed to process during the grinding process of the pre-ac- cepted workpiece will be shipped to the buyer together with the qualified test pieces or the shipped machine.

CNC step-down grinder H30 Technical Specifications

During the pre-acceptance process, the buyer has the right to make reasonable rectification suggestions for the equipment, and the seller can make rectifications after both parties agree; 4. After the pre-acceptance is qualified and the seller signs the pre-acceptance document, the seller can ship the equipment to the buyer.

Installation, commissioning and final acceptance

1. After the equipment arrives at the buyer, the seller will send relevant technical person- nel to install and debug the equipment.

2. For details on the installation and commissioning until the equipment works normally, please refer to the "Delivery Acceptance Form".

3. The seller will grind the workpiece on site according to the actual situation and meet the requirements of the drawings. The final acceptance will be qualified after the buyer's

acceptance personnel signs.

Technical training and services:

1. The seller's equipment arrives at the buyer and passes the final acceptance. The warran- ty period is one year. Under normal use, damage is free of charge (labor and parts

are free). After the warranty period, the seller provides paid services to the buyer for a long time.

2. The seller shall send technicians to train the buyer's operators for the following contents free of charge: normal commissioning of grinders, replacement of grinding wheels, main- tenance of hydraulic oil circuits, replacement of oil seals, normal maintenance of electri- cal components, safety specifications for grinder operation, basic knowledge of grinder

operation, basic fault judgment of grinders, etc.

3. The buyer needs to arrange grinder operators in advance, and the training time is 1-3

working days. The buyer shall bear the responsibility for the equipment failure to be

handed over and trained due to problems with the buyer's operators. If the buyer requests to extend the training time, the relevant fees will be charged according to the buyer's

training fee standard.

4. During the training of the seller's technicians, the buyer will provide free lunch, and other food and accommodation expenses shall be borne by the seller.

5. For complaints about equipment failure, the seller shall respond and provide solutions within 12 hours, and can send people to the site to solve the problem within 48 hours

according to the equipment situation.

.jpg)

.jpg)

.jpg)

.jpg)