Machine Tool Overview

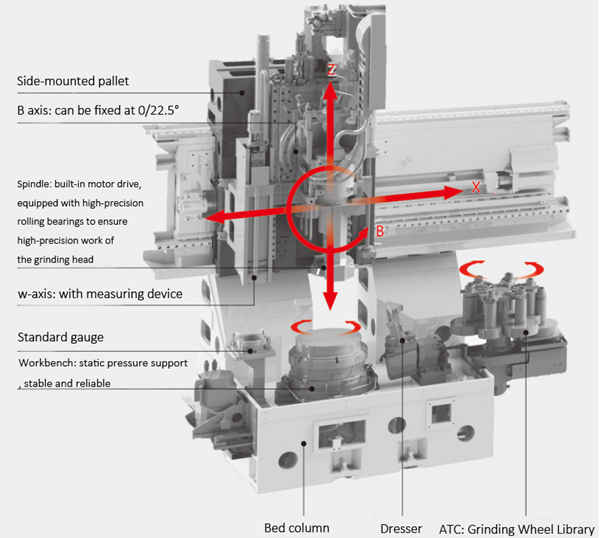

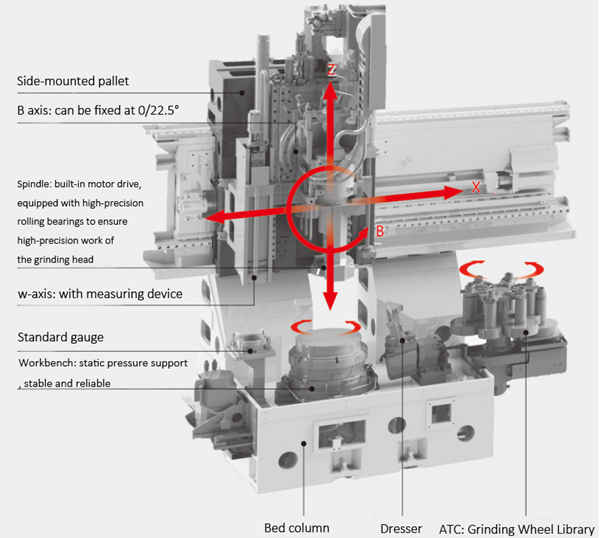

This grinder is a CNC vertical compound grinder with a vertical structure for both the work spindle and the grinding wheel spindle, and the sliding of the X-axis (feed axis) and Z-axis controlled by NC.

This grinder was developed with the goal of facilitating alignment of workpieces and improving grinding accuracy when grinding the inner diameter and end face of large workpieces. It significantly shortens the debugging time and achieves high-precision grinding such as roundness. In addition, it is controlled by NC, and the inner diameter, outer diameter, and end face can be processed in one clamping, realizing the intensive process. Based on the compound processing capability and high-precision processing capability of the original NVGI series, by completing a simple structure and reducing and standardizing useful options, it has achieved more affordable and efficient productivity than ever before.

Machine tool characteristics

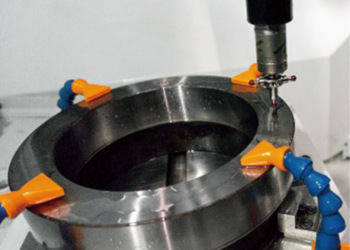

1) The use of vertical spindles greatly improves operability

The workpiece spindle and the grinding wheel spindle are both vertical structures, which can easily complete the loading and unloading of workpieces. At the same time, centering and preparation processes can be completed with both hands.

2) The use of vertical workpiece spindles ensures that the roundness of the manufacturer's standard test piece is within 1um

Compared with the previous horizontal spindles, the vertical spindle will not be affected by the weight of the chuck and the workpiece, causing the spindle to bend, making it easy to achieve high roundness.

3) Heat protection measures are implemented in various parts to ensure high precision processing

The X-axis and Z-axis are controlled by a 0.05μm fully closed-loop magnetic scale to prevent errors caused by ball expansion and contraction. In addition, the coolant temperature management device that was previously an option is standardized, so that the coolant flowing into the machine tool is treated by the temperature management device, so the thermal change in the bed is kept to a minimum.

4) Dual positioning function added to the grinding wheel table

The grinding wheel table is equipped with a dual positioning function of 0 degree and 22 degree for the grinding wheel axis as standard. One grinding wheel axis can use a flat grinding wheel and a beveled grinding wheel respectively. By using a beveled grinding wheel, efficient end surface processing can be achieved.

1. The grinding of the inner hole, outer circle, cone surface and end face of the part can be completed in one clamping.

2. Grinder structure

a. Integrated bed column

High shock absorption and high thermal stability ensure long-term stability of the machine tool and are not prone to deformation.

b. Snap-on sliding seat

This allows the beam to better support the gravity of the slide and spindle in the vertical direction.

c. Linear axis positioning accuracy

a. Integrated bed column

High shock absorption and high thermal stability ensure long-term stability of the machine tool and are not prone to deformation.

b. Snap-on sliding seat

This allows the beam to better support the gravity of the slide and spindle in the vertical direction.

c. Linear axis positioning accuracy

X-axis positioning accuracy: 3.70um

X-axis repeat positioning accuracy: 2.87um

Z-axis positioning accuracy: 2.82um

Z-axis repeat positioning accuracy: 2.13um

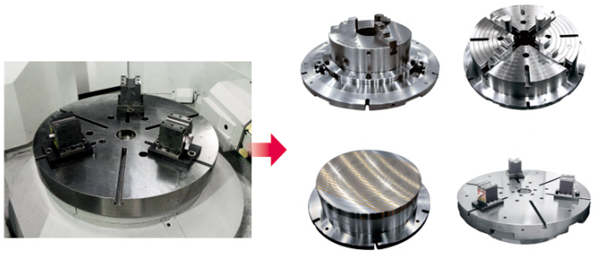

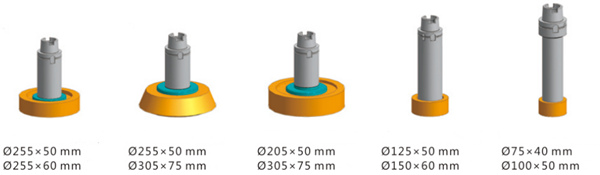

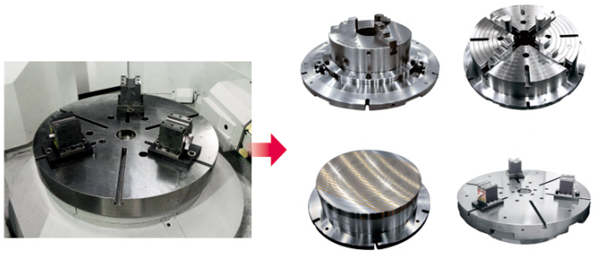

d. Static pressure support workbench

The suitable clamping can be flexibly selected according to the workpiece shape or processing form

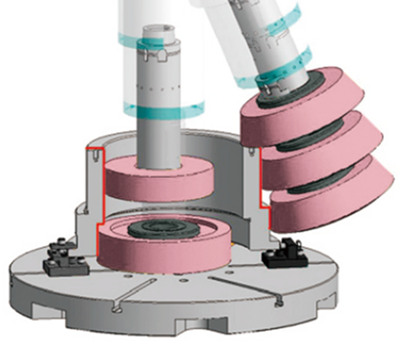

3. ATC: Grinding Wheel Library

4. Grinding machine configuration

4. Grinding machine configuration

.jpg)

a. The 22.5°rotatable B-axis allows one grinding wheel to complete cylindrical and end face grinding more efficiently.

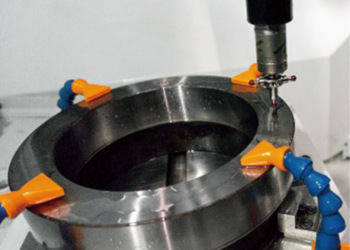

b. Online measurement device In mass production, especially large-diameter workpieces or deep-hole workpieces, errors caused by manual measurement can be avoided, processing time can be saved, and fully automatic compensation can be achieved.

c. Grinding wheel dressing device

Conducive to the dressing of CBN grinding wheels, the rotating diamond roller dresser is equipped with multi-point diamonds on the rotating disc.

d. Cooling/filtration system

It adopts two-stage filtration with magnetic roller and centrifugal separation, and the filtration precision is 0.01mm, ensuring that the cleanliness of the return water will not affect the grinding surface finish.

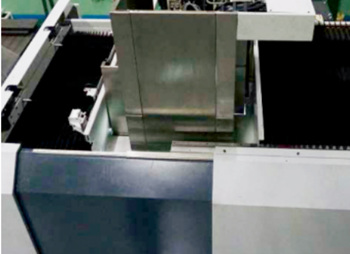

e. Fully enclosed guard

The telescopic shield can be easily opened during loading and unloading and completely closed during cycle processing to reduce grinding noise and prevent the spread of water mist.

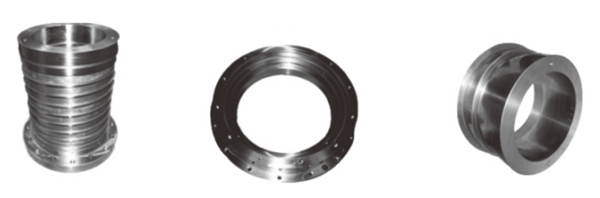

5. Workpieces

5. Workpieces

Suitable for grinding discs/short shafts/sleeves/rings and other parts Work

Moresuperhard Grinding Products Applicable to This Vertical Grinding Machine

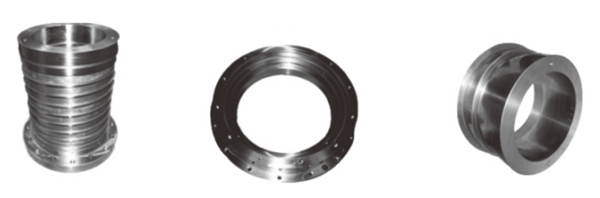

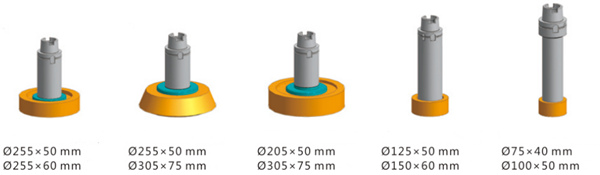

1. Cylindrical Grinding Wheels:1A1/1V1 Conventional Grinding Wheels & Resin Bond CBN Grinding Wheels

► OD cylindrical grinding wheel (1A1/1v1 shape)

► Diamond sanding belts

► Diamond internal grinding wheel

► Diamond honing stone

Model: 1A1 diamond wheel (diameter up to 1100mm)

2. Internal Resin Bond Grinding Wheels

► Application: harder alloys, ceramics and cermet.

► Bonded: resin bond

3. Diamond Dresser for Dressing

► Single point diamond dressers

► Multi point diamond dressers

► Forming diamond dressers

► Impregnated diamond dressers

.jpg)