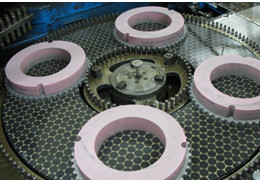

The main features of the reaming process are its reaming honing head and the actual reaming process. Compared with the traditional honing process, the reaming honing head is pre-set to the final machining size required by the workpiece. Therefore, the cutting process of reaming only requires 1 to 3 reciprocating strokes to be completed. The thickness of the metal layer removed by the honing head is 2 to 20 mm, and the shape and dimensional accuracy of the hole can be improved by one level after reaming, and the surface roughness value can reach Ra0.32 and dimensional accuracy can reach IT1. the most important feature of the reaming process is that the positional accuracy of the hole can be improved to a certain extent.

The material of

honing bar is generally made of diamond and boron nitride (CBN) material, the characteristics of these two materials ensure the improvement of honing quality and efficiency with the following features: 1. long life ensures complete automation; 2. good dimensional stability can obtain excellent geometric accuracy; 3. large grinding volume can be used and honing can replace fine boring.

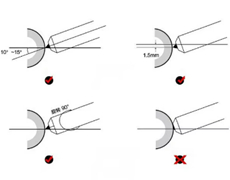

The rotating and reciprocating motion of the honing head is the main parameter of honing, and its rotating circumferential speed is 30~50m/min, but its reciprocating speed is 0.5~6m/min, which is much lower than that of traditional honing. The honing in and honing out lengths have little effect on the cylindricity of the processed hole during the reaming process.

What is the reaming and its characteristics?

The reaming process is developed on the basis of traditional honing, and the reaming process incorporates some of the characteristics of reamed hole processing. Compared with traditional honing, in the reaming process, the number of reciprocation of the honing head is generally 1-3 times, the number of honing axes is determined according to the margin, the circumferential speed of the honing head is 30-50m/min, the amount of honing in and honing out has little influence on the cylindricity of the machined hole, and the arrangement of honing axes can be vertical and horizontal, the honing fluid can be oil or water agent (high permeability), and the filtration precision of the filtering device is required to be high.

.jpg)

After adopting reaming and honing process for connecting rod production, the size and shape accuracy of connecting rod big head hole and small head hole are greatly improved. At the same time, the relative position accuracy of the two holes is improved. The reaming process can completely guarantee the product requirements, and its Cm value is greater than 1.33, and its stability control ability can also be guaranteed. Since the adoption of the reaming process, the correction rate of the parallelism and crossness of the connecting rod has been reduced from 90% to 1-5% now, which effectively solves the problem of poor parallelism of the connecting rod.

What is the practical application and effect of reaming process in the production of connecting rod?

1. Application of traditional honing process production

The main problem of applying traditional honing in actual production is that the cylindricity of the workpiece after processing is seriously over poor, and the shape of the workpiece hole is saddle-shaped, which is a problem that cannot be solved: because traditional honing uses profiling, i.e., it is self-positioning with the processed hole during processing, so traditional honing cannot solve the problem of hole position accuracy, and even plays a destructive role. After adopting the reaming process, the above two problems are well solved.

2. Production situation after applying reaming process

After adopting the reaming process in the production of connecting rod, the size and shape accuracy of the large and small head holes of connecting rod are greatly improved. At the same time, the relative position accuracy of the two holes is improved.

The reaming process can completely guarantee the product requirements, its Cm value is greater than 133, and its stability control ability can also be guaranteed.

Since the adoption of the reaming process, the correction rate of connecting rod parallelism and crossness has been reduced from 90% to 1~5% now, which effectively solves the problem of excessive parallelism of connecting rod.

---EDITOR: Sarah Shi,Jackie Wang

---POST: Jackie Wang

.jpg)