1. Body of Moresuperhard High Precision CNC Centerless Grinding Machine

The body and main components are made of high-grade cast iron FC30 in one casting. After artificial normalization heat treatment, and then after natural aging treatment. The main components are processed by YASDA, MITSUI SEIKI, TOSHIBA, ELB and other world-class equipment in one clamping process. Precision dimensions can reach the micron level, ensuring high accuracy of the basic components of the equipment. The machine bed is designed through finite element analysis of high strength and rigidity of the whole dense baked cast iron bed structure, with excellent heat dissipation and vibration absorption ability, the internal use of cross-bar structure of the low center of gravity design, to ensure that the overall rigidity of the equipment anti-vibration, improve the stability of the grinding process, and maximize the maintenance of precision machine tools. The bed is designed with centralized lubrication reflux oil circuit, high drainage slope and large outlet size, which can quickly and efficiently remove the machine tool grinding fluid.

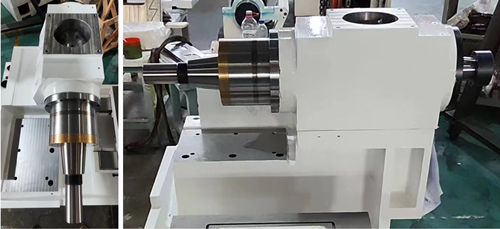

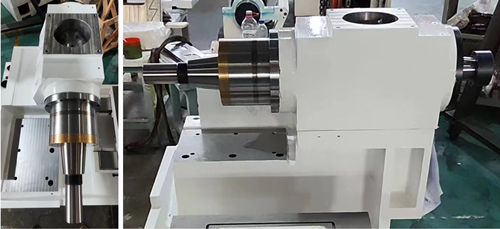

2. Spindle system of Moresuperhard High Precision CNC Centerless Grinding Machine

The spindle adopts Japanese technology of double hydrostatic front support spindle, pure liquid lubrication, low friction resistance, low power consumption, high transmission efficiency; during normal operation and frequent startup, there will be no direct metal-to-metal contact causing wear and tear, good precision retention and long service life; since the floating of the shaft diameter is realized by the pressure of external oil, it has a high load-bearing capacity under various relative motion speeds, and the speed change has little effect on the oil film; the lubricating oil has little influence on the oil film; the lubricating oil is designed to remove the machine grinding fluid quickly and efficiently. Small impact on the oil film; lubricating oil layer has good anti-vibration properties, the spindle running smoothly; oil film has the role of compensating for errors, can reduce the impact of errors caused by the shaft and the bearing itself, the spindle rotary accuracy is high.

3. Adjusting wheel drive system of Moresuperhard High Precision CNC Centerless Grinding Machine

Adjusting wheel spindle drive motor adopts Delta servo motor, speed control 0-250rpm (digital control) can be arbitrarily set speed, adjusted to the best linear speed, when the adjusting wheel outer diameter changes can still maintain the same linear speed, grinding out the best products.

The servo motor is cleverly designed to be mounted on the adjusting wheel box and directly driven by synchronous belt, which can hit the tilting angle with the adjusting wheel at the same time when grinding to ensure that the two pulleys are always parallel. Overcome the loss of inertia and the adverse effects of chain angle caused by the old centerless grinder with chain multi-section drive. It also avoids frequent replacement of chain and zipper spring.

4. Spindle circulating oil system (automatic oil lubrication) of Moresuperhard High Precision CNC Centerless Grinding Machine

Spindle automatic lubrication circulating oil (high grade spindle oil 10#) and oil pressure dressing device is the same oil pump, external tank, easy to clean and change oil, spindle circulating oil is filtered by two oil filtering devices and equipped with pressure controller to ensure the life of the spindle. Cooling adopts double-circuit cooling system to ensure the constant temperature of spindle oil.

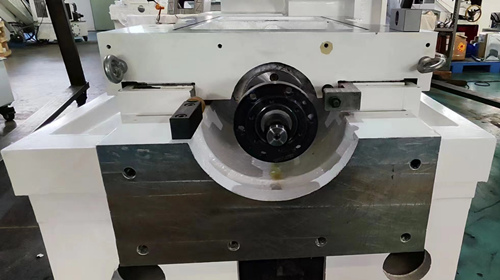

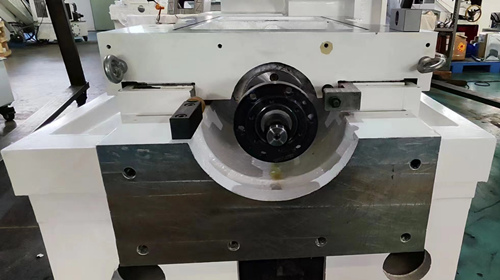

5. Double flat rail type bed structure

Double flat rail type guide structure, 90mm wide flat rail sliding, the bottom plate is designed with curved oil filling groove, there is a lubricant reflux channel between the rail surfaces, the feed slide plate is affixed with wear-resistant rubber, which reduces the coefficient of friction and greatly reduces the wear of the rail surfaces, improves the feeding speed, improves the contact rigidity, and facilitates the replacement of the wear-resistant rubber at a later stage and increases the service life, and the flat rail surfaces are all made of high-frequency heat treatment to improve wear resistance. Improve the wear resistance.

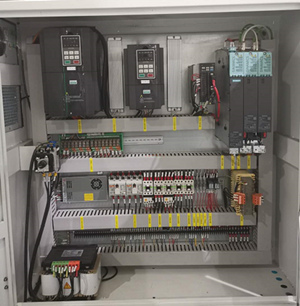

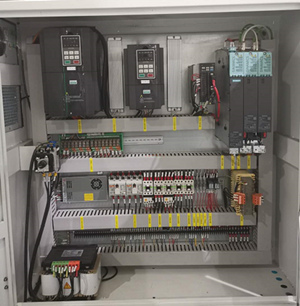

6. Circuit system

The circuit of the whole equipment adopts Schneider circuit system, which is beautiful and durable, with good operability. Higher and bigger electric box is convenient for operation and more conducive to the heat dissipation of the circuit system.

7. Numerical control system

Adopting Siemens numerical control system and after the secondary development of Hautman, Chinese man-machine dialogue interface, easy to learn; with the corresponding brand servo motors, one-axis automatic knife feed, two-axis numerical control molding sand trimming, good compatibility and accurate knife feed.

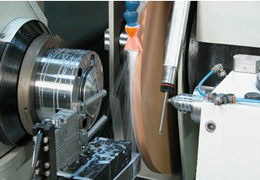

8. Schematic diagram of automatic dressing device: (two-axis CNC system automatically dresses the grinding wheel and compensates automatically.)