https://www.mogrinding.com/products/vitrified-diamond-cbn-wheel/peripheral-diamond-wheel-for-indexable-inserts-especially-cbn-inserts.htmlWhat is internal stress?

All metals will deform (when stretched or compressed) to a greater or lesser extent when subjected to a force. This deformation is a visible sign of stress in the metal and is called metal strain. The stresses that are equilibrated inside the object in the absence of external forces are called internal stresses (e.g. tissue stresses, thermal stresses, residual stresses that remain at the end of the processing...).

Natural aging means that the component is stored in nature and uses the effect of time to relax the residual stress through repeated changes in climate and temperature. Usually, the workpiece will be placed under natural conditions after machining, so that the internal stress of the workpiece will be released naturally and thus the residual stress will be eliminated or reduced, which will lead to the relaxation of the residual stress and the dimensional accuracy will be stabilized.

How to correct internal stress?

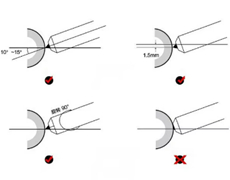

Stress correction, when machining the base body, the base body is clamped to the chuck and there is a squeezing force on the base body, when the extra base body is hollowed out, the bottom of the base body will be concave to the inside under the action of the chuck fixture and the hollowed out base body, at this time the inner hole is actually tapered, generally the inner hole will have about 3 wire error, so the inner hole cannot be processed in place at one time, generally leave 30-50 wire margin, other parts After machining, at least 24 hours of stress relief will be left, and then the positioning hole will be processed in the machining center. When drilling the positioning hole, the grinding wheel is placed positively, and when drilling the hole, the bottom surface of the substrate will have an impact, and the bottom surface will have a downward protruding deformation, so after drilling the hole, at least 24 hours of stress relief will be left, and the inner hole of the grinding wheel will be processed again to the size required by the customer, and finally the reference surface will be processed again.

How do we reduce stress when making grinding wheels?

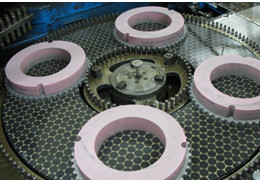

Grinding wheel stress relief design - positioning hole, on the grinding machine with tension to pull back the deformation of the grinding wheel, especially peripheral grinding large bore, narrow wall width, poor resistance to pressure, chuck clamping is easy to cause a large roundness error, grinding wheel bore is elliptical, machining center drilling, the flatness and parallelism of the substrate by pressure deformation. Peripheral grinding wheel factory, parallelism and flatness is not very good, peripheral grinding wheel positioning holes are generally 6 or 8, or even more, on to the grinding machine positioning hole design is also designed according to the stress distribution, in order to have better parallelism and flatness when the grinding wheel is clamped to the grinding machine.

However, there are also small diameters and small bores

in peripheral grinding, with a wide base wall and a strong ability to withstand stresses, and this base has less stress deformation and fewer positioning holes.

The grinding wheel of

Moresuperhard is mounted by means of an arbor during finishing, in order to minimize the stress generated by the mounting, so that the grinding wheel can obtain better form tolerance and improve the accuracy of the grinding wheel.

If you want to know more about the internal stress and the content of grinding wheel production, welcome to consult the technical engineer of us!

---EDITOR: Yun Li,Jackie Wang

---POST: Jackie Wang