With the increase of global environmental awareness and the transformation of energy structure, new energy vehicle industry is developing at an amazing speed. As the core components of new energy vehicles, such as electric motors, batteries, car bodies, etc., their precision machining can not be separated from high-precision and high-efficiency grinding machines and grinding wheel grinding technology. This brings great market opportunities for the grinding machine and grinding wheel industry, but also puts forward higher requirements for technology.

First, new energy vehicles bring new grinding needs:

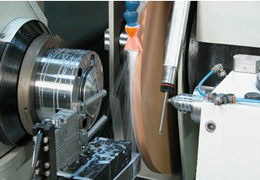

Motor Processing: The core components of new energy vehicle motors, such as rotors and stators, require extremely high dimensional accuracy, surface roughness and tolerance. This requires grinding machines with high rigidity, high precision and high stability, while the grinding wheels also need to have good wear resistance and shape retention to meet the needs of efficient and precise grinding.

Battery Processing: As the power source of new energy vehicles, the safety, reliability and service life of batteries are of paramount importance. The processing of battery shells, pole pieces and other components requires high-precision grinding to ensure their dimensional accuracy and surface quality, while avoiding the generation of burrs and cracks.

Automotive body machining: The lightweight body of new energy vehicles is the development trend, and the application of aluminum alloy, high-strength steel and other lightweight materials is becoming more and more widespread. The processing of these materials presents new challenges to grinding machines and grinding wheels, and requires the development of new grinding processes and grinding tools to improve processing efficiency and surface quality.

Second, the new energy automobile grinding processing considerations:

High precision: New energy automobile parts have extremely high requirements for precision, so it is necessary to choose high-precision grinding machines and grinding wheels, and strictly control the grinding parameters to ensure processing precision.

High efficiency: the new energy automobile market demand is large, need to improve production efficiency. High-speed grinding, power grinding and other high-efficiency grinding technologies can be used, while optimizing the grinding process to shorten the processing time.

Environmental protection: The new energy automobile industry focuses on environmental protection, and the grinding process needs to reduce the generation of dust, noise and waste liquid, and adopt green grinding fluid and dust removal equipment.

Automation: In order to improve production efficiency and product quality, automated grinding production line can be used to realize automated loading and unloading, automatic detection and automatic compensation and other functions.

Third, seize the opportunity to meet the challenge:

The rapid development of the new energy automobile industry for the grinding machine and grinding wheel industry has brought great market opportunities, but also put forward higher requirements for technology. Grinding machine and grinding wheel enterprises need to follow the market trend, increase R&D investment, and develop high-precision, high-efficiency, environmentally friendly grinding equipment and grinding tools to meet the needs of the new energy automobile industry.

IV. Moresuperhard Grinding Machines Advantages:

Rich product line: We provide various specifications and models of grinding machines and grinding wheels to meet the needs of different customers.

Advanced technology: We have a strong R&D team, constantly developing new technologies and products to provide customers with better quality solutions.

Perfect service: We provide pre-sale, in-sale and after-sale services to solve customers' worries.