The hydraulic industry occupies a very important position in industrial manufacturing. Hydraulic systems are widely used in mechanical equipment to transfer and control energy. The following is a detailed description of three typical machining cases in the hydraulic industry:

1.Hydraulic piston pump - piston

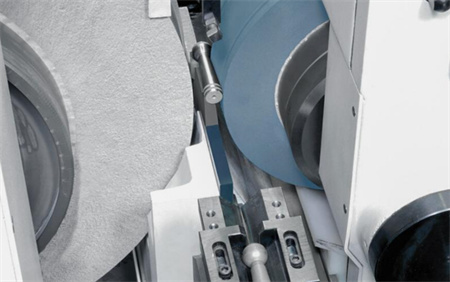

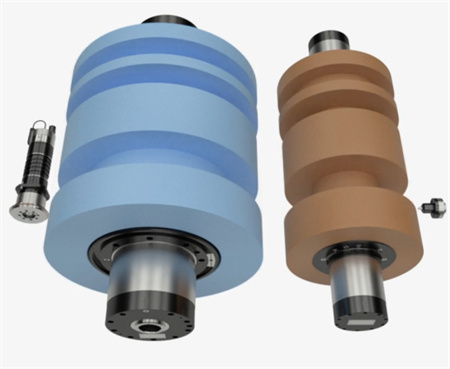

Hydraulic piston pump is a common high-pressure pump, widely used in construction machinery, mining machinery and other fields. The piston is the core component of the hydraulic piston pump, and its machining quality has a direct impact on the performance of the pump. The machining of the plunger piston mainly includes high-precision cylindrical grinding, internal hole machining and surface treatment.

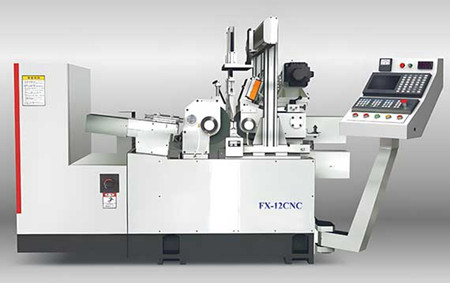

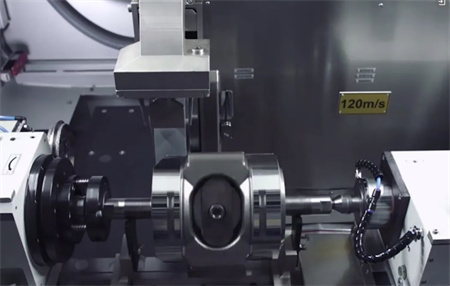

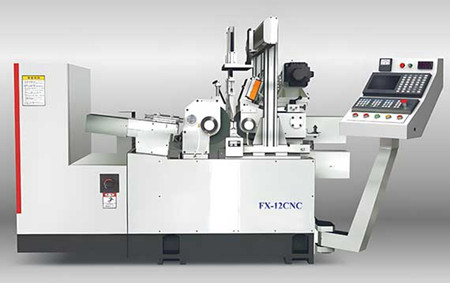

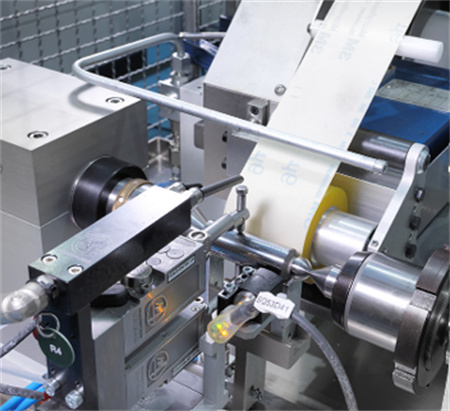

Moresuperhard Centerless grinding machine

Moresuperhard Centerless grinding machine

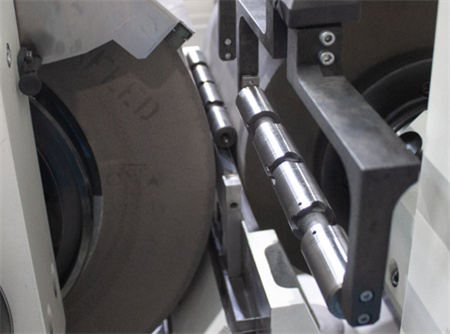

Complete Piston Plunge Grinding

Complete Piston Plunge Grinding

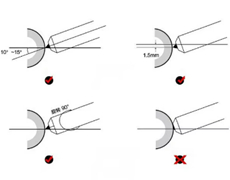

Complete valve and ball grinding in one operation

Cylindrical or conical valve body

Tolerance of the diameter: 5μm

Cylindricity: 3μm

Surface roughness< 0.2 μm

Guarantees long-term accuracy and stability

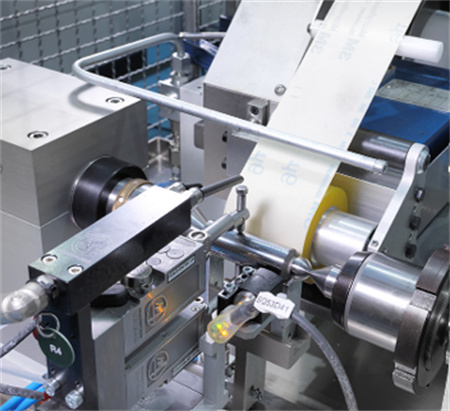

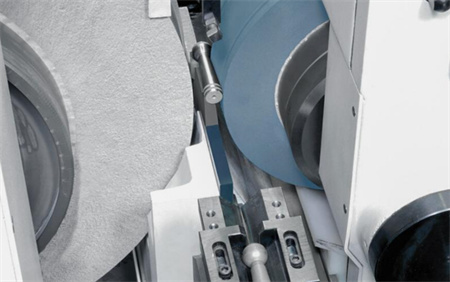

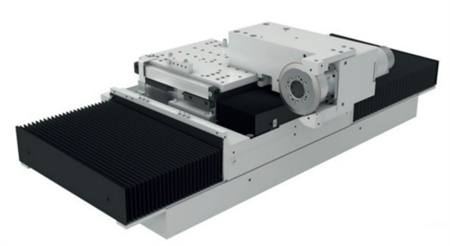

Dressing devices run with linear motors

Diamond roller for dressing electro-spindle

Simultaneous dressing of both wheels possible

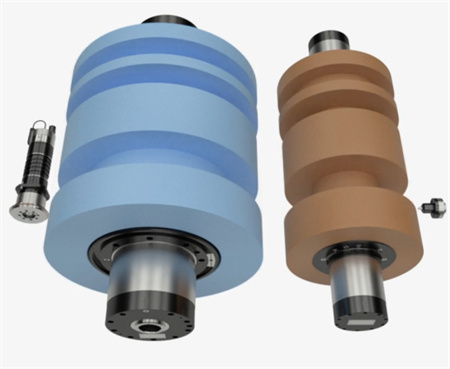

High-speed Grinding Solution With Moresuperhard Centreless Grinding Machine and CBN Grinding Wheels

CBN wheel line speed 120m/s, conventional grinding wheel 80m/s

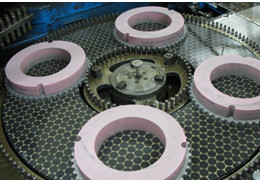

Superfinish machining

For Cylinder vale body of piston

Surface roughness < 0.08 um

Integrated superfinishing solutions that do not extend machine cycle time

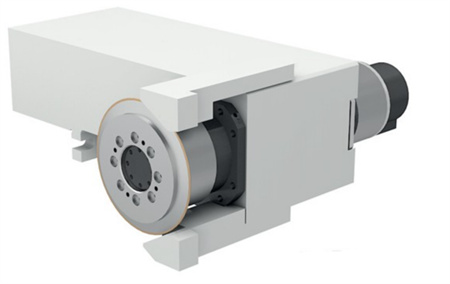

2. hydraulic Control Valve

Hydraulic control valve is the core component in the hydraulic system, responsible for regulating the flow, pressure and direction of the hydraulic fluid. The key components of the control valve include spool and sleeve, and their machining quality directly affects the valve's sealing and action sensitivity.

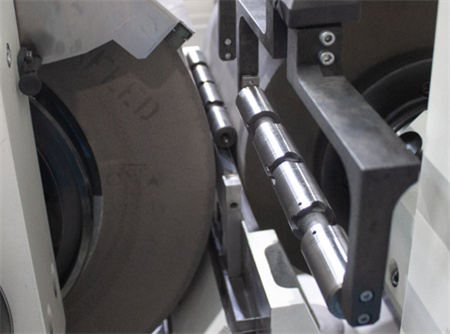

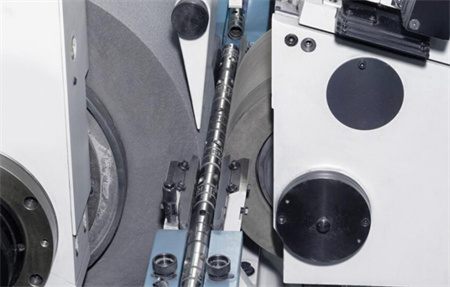

Plunge centerless grinding of hydraulic control valve spool

Plunge centerless grinding of Spool valve

Tolerance of the diameter: 3μm

Cylindricity: 3μm

Roundness:1μm

Surface roughness:< 1 µm

Offline measurement solutions with automatic feedback with size compensation

Minimum machine setup time

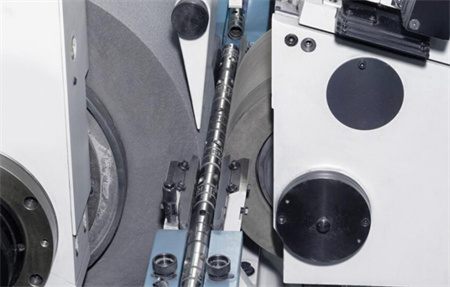

Through Centerless Grinding of Hydraulic Valve Sleeve

Straightness : 1μm

Roundness:1μm

Surface roughness:< 0.15 µm

Offline measurement solutions with automatic feedback with size compensation

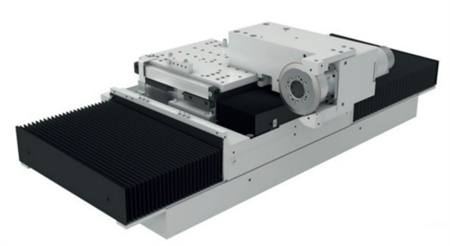

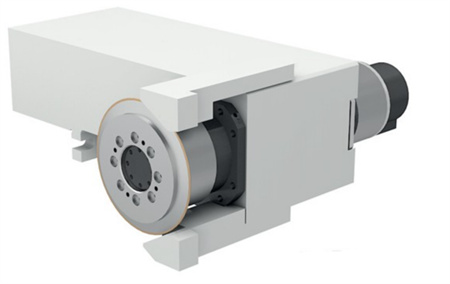

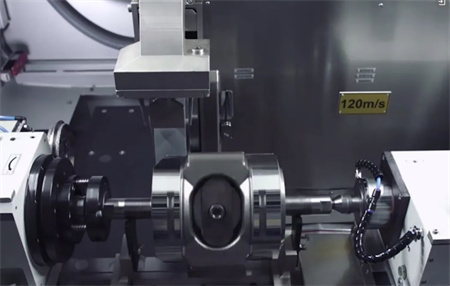

3.External Grinding of Hydraulic

Hydraulic cylindrical grinding is widely used in the processing of various types of cylindrical parts in the hydraulic system, such as plungers, piston rods and valve cores. Cylindrical grinding is a high-precision machining process used to process the cylindrical surface of parts to ensure their dimensional accuracy and surface finish.

plunger pump

Tolerance of the diameter: 30μm

Roundness:4μm

Straightness : 2μm

Surface roughness:Rz Max<1 um(Rmr 0.3>85%)

Grinding line speed up to 140 m/s

Direct drive B-axis and multi-wheel applications can realize versatility

Automatic production, CNC control,loading and unloading time 2-6s

Summary of Processing Case for Hydraulic Industry:

Processing in the hydraulic industry has extremely high requirements for precision and surface quality, especially in the processing of key components such as pistons and valves, where any small error may affect the performance of the entire system. The high quality and reliability of hydraulic system parts can be ensured through advanced grinding technology, precision machine tool machining and surface treatment processes.