The crankshaft is a key component in a reciprocating piston engine, which converts the linear reciprocating motion of the piston into rotational kinetic energy, thus providing driving power for vehicles or mechanical equipment. The crankshaft derives its name from its unique structure - the “zigzag shaft”, which can realize the energy conversion through the connection between its zigzag place and the connecting rod. In this article, we will introduce the working principle of crankshaft, key parts, classification and its important role in the engine.

Working Principle of Crankshaft

The role of the crankshaft is to convert the linear kinetic energy generated by the piston movement into rotational kinetic energy. When the piston moves up and down in the cylinder, the crankshaft is rotated by the connecting rod. The connecting rod journals (also called crankshaft pins or crankshaft arms) of the crankshaft are the parts that connect the connecting rods to the crankshaft. Due to the radial displacement between the center of the connecting rod journals and the center of the crankshaft's axle, this allows the reciprocating motion to be converted into a continuous rotary motion.

Crankshaft Materials and Manufacturing Processes

The crankshaft is the component of the engine that is subjected to enormous pressure and torque, especially from the explosive forces in the combustion chamber. As a result, crankshaft materials must be extremely strong and durable. Common crankshaft materials include:

Forged steel crankshafts: utilizing a forging process for high strength and toughness, commonly used in high performance engines.

Cast Iron Crankshafts: Manufactured using gray cast iron or ductile iron for engines with high cost control requirements.

Aluminum or titanium crankshafts: used in some special high-performance engines to reduce weight and improve efficiency.

The main bearings of the crankshaft are usually embedded with wear-resistant and precision bearing spacers to ensure stable operation even under high loads. In addition, the crankshaft is equipped with multiple oil holes for oil flow to ensure adequate lubrication and cooling during operation, thus extending its service life.

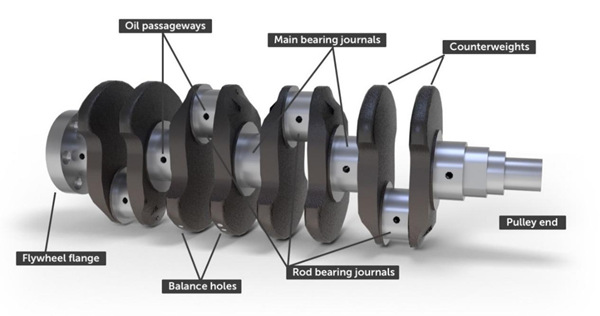

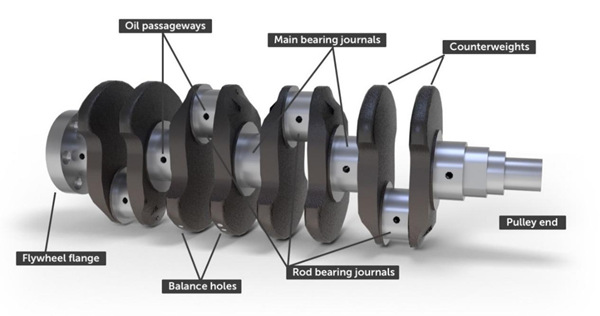

Crankshaft structure and critical parts

A typical crankshaft consists of the following key parts:

Flywheel flange: Used to connect the flywheel and help stabilize the angular speed of the engine.

Oil passageways: For oil flow to provide lubrication and cooling.

Balance hole: Used to adjust the balance of the crankshaft.

Main bearing journals: Main bearings support the crankshaft as it rotates.

Rod bearing journals: Connected to the connecting rods to transfer the kinetic energy of the pistons.

Counterweight: Helps to balance the rotation of the crankshaft and reduce vibration.

Pulley end: Used to connect pulleys to drive other accessories.

Thrust face: Limits axial movement and prevents crankshaft displacement.

Crankshaft classification

According to material, type and application, crankshafts can be categorized as follows:

1. Material classification

Cast iron crankshafts

Gray cast iron crankshafts

Ductile cast iron crankshafts

Forged steel crankshafts

Alloy Steel Crankshafts

High Carbon Steel Crankshafts

Stainless Steel Crankshafts

Aluminum and titanium crankshafts

2. Type classification

Single crankshafts

In-line crankshafts: for in-line engines.

V-type crankshafts: for V-type engines, connecting V-arranged pistons.

Multiple crankshafts

Horizontally opposed crankshaft: Commonly used in horizontally opposed engines, connecting left and right opposed pistons.

W-type crankshaft: Used in W-type engines with complex structure.

Special crankshafts

Hybrid crankshafts: used in hybrid engines, combining electric and fuel power transmission.

Rotary crankshafts: used in rotor engines.

Variable Crankshafts

Variable Valve Crankshafts: used in engines with variable valve systems to optimize valve control.

Importance of the crankshaft

The stability and durability of the crankshaft in a four-stroke engine cycle has a direct impact on engine performance. The flywheel and vibration dampers on the crankshaft help maintain smooth rotation and reduce torque vibration. A high-quality crankshaft can dramatically improve the operating efficiency and life of an engine, ensuring stable operation under high loads and harsh conditions.

Moresuperhard Grinding Machine and Grinding Wheels for Crankshaft Processing

Manual Crankshaft Grinding Machine

►Easily adjusted outboard counterweights

►Built very heavy with widely spaced ways to assure positive alignment of the wheelhead to the table

►The controls are easier to use

►Longer machine life, longer grinding wheel life and greater safety

Camshaft Grinding - Vit Cbn Wheel

► Grinding camshaft

► Model: 1A1 Vit cbn wheel

► Suitable CNC cam Grinder: Toyoda, Schaudt, Landis, Junker etc

Conclusion

As one of the core components of an engine, the crankshaft's material, processing technology and design structure are critical to engine operation. Choosing the right material and type of crankshaft can not only improve the performance of the engine, but also extend the service life of the equipment. If you are looking for

high quality crankshafts grinding machines and grinding wheels or need related technical advice, please feel free to contact our professional team. We offer customized solutions to help your engine achieve optimal performance.