What chracteristics does Titanium alloy have?

Titanium alloy has the characteristics of light weight, high strength, corrosion resistance, heat resistance, high toughness, low thermal conductivity, and thus is widely used in aerospace, automotive, shipbuilding, medical chemical and other parts processing. However, the poor thermal conductivity of titanium alloy causes high temperature in the grinding zone, which causes bonding, diffusion and strong chemical reaction between titanium alloy and abrasive, resulting in grinding wheel blockage and burn.

How to grinding Titanium alloy workpieces?

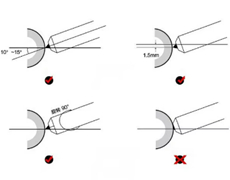

Titanium alloy grinding requires that the grinding wheel adhesion is small, wear is small, not easy to plug, and the grinding temperature is low. Conventional grinding wheels should usually choose a soft or medium hardness, large porosity grinding wheel with loose organization, that is corundum grinding wheel and silicon carbide grinding wheel. Superhard grinding wheel should choose cubic borax nitride

(CBN)grinding wheel.

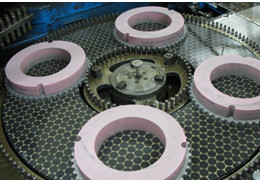

Moresuperhard Grinding Solution Recommendation--Resin CBN Grinding Wheels

The picture on the left shows the green carbon grinding wheel used by the customer. The picture on the right is the customer's new choice of

Moresuperhard resin CBN grinding wheel.

The customer's feedback is that the green carbon grinding wheel has low grinding efficiency and large grinding consumption. The resin CBN grinding wheel is used under our recommendation. After using it, he said that the grinding effect was very satisfactory to him, and he will continue to use our vitrified CBN grinding wheel to process and grind titanium alloy workpieces in the future.

What should we pay attention to when grinding Titanium alloy workpieces?

When grinding with corundum grinding wheel, due to the strong adsorption capacity of aluminum and titanium in the workpiece, there will be serious adhesion, and the use of green silicon carbide grinding wheel is lighter adhesion, burn and crack phenomenon is less. Therefore, the general use of green silicon carbide grinding wheel, usually using 36#-80# grit size.

When grinding titanium alloy with borax nitride grinding wheel, the grinding temperature and the residual stress on the machined surface are very low, which can effectively restrain the generation of cracks, and obtain higher workpiece surface quality and grinding efficiency. Better cooling effect with oil.

---EDITOR: Sarah Shi,Jackie Wang

---POST: Jackie Wang