Recently, we had a customer from the glass industry who had a grinding problem and shared it with Moresuperhard. He said that the workers in his factory cuts glass with Metal Cutting Wheels. But when cutting the glass, the glass was often unevenly ground or even cracked. In order to find out more about the cause of the customer's grinding problem, we conducted a quality inspection of the customer's cutting wheels as soon as we received the samples.

Specific Problems with Customer Buying Other Brands of Metal Cutting Wheels:

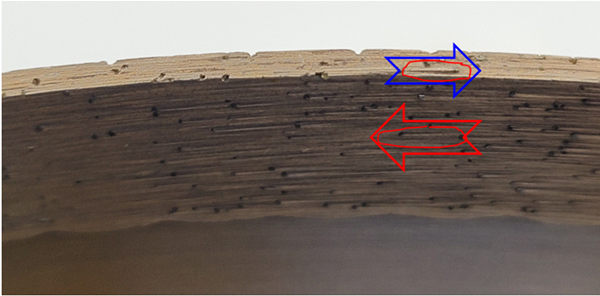

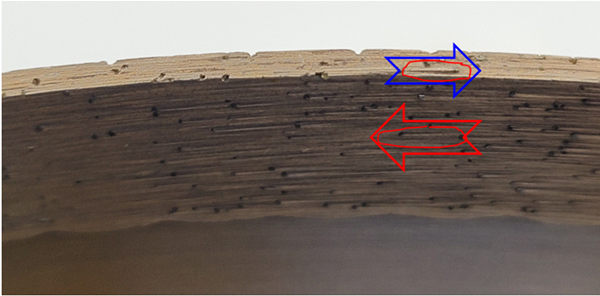

When our quality inspector was told the customer always encountered this problem with opening the diamond layer properly on the cutters. On some of the cutting wheels the customer bought, we found that there is somtimes a different direction opened dimond layers. Our quality inspector assume that the customer put the cutting wheel on the machine and open it, sharpened it from one side. We asked the customer and he said diamond segment was open well and each grain had a backing tail of metal binder at the back, which was ok.

However, our quality inspector found the direction of the support tail is in the opposite direction as on opposite side. Of course, when you look at a sharpened diamond layer- segment , you could see it in the right direction. Now we are still talking about side opening - sharpening of the diamond layer- segment. If you hold the sharpened wheel in your hand, mark with a pencil the direction of rotation in relation to the opening direction of the diamond layer and do not turn the cutter, but make an arrow from the bottom side in the same direction as on the top side and you will see that the sharpening is in the wrong direction on another side according to the arrow.

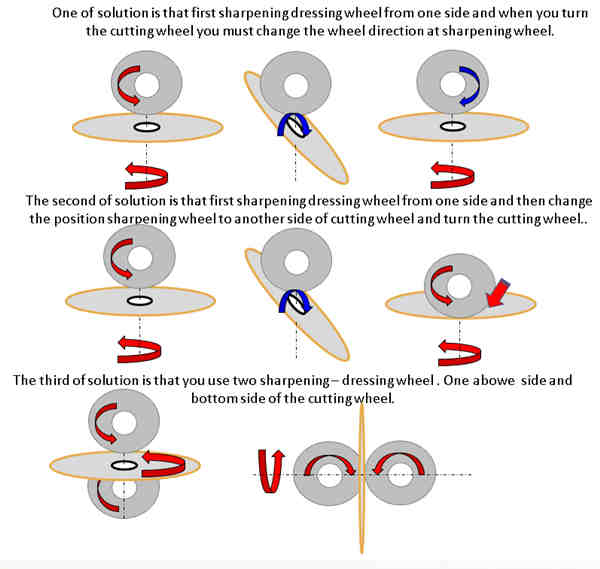

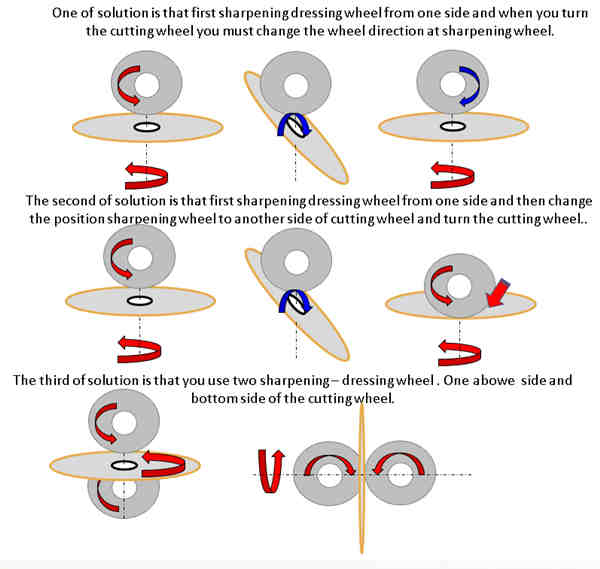

During the discussion, one of our professional engineer share us three applicable grinding solutions.

However, from a long term, this is a quite considerable problem that needs to be tackled. We recommended our Metal Cutting Wheels to our customer, and after receiving the product and applying it, the customer stated that they had a good experience with our product, and for the time being, they did not have any of the previous machining problems.

Moresuperhar Summary of Improvement in Metal Cutting Wheels:

Our development group made discussions and decided to improve our producing standard:

our workers will be continuously required to pay attention to keeping the direction of processing the same when opening and sharpening the grinding wheels so that our cutting wheels will bring more convenience to our customers.

---EDITOR: Alan Wang,Jackie Wang

---POST: Jackie Wang