Application:

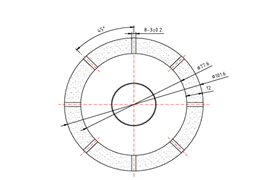

Workpiece: crankshaft

Grinding position: flange end

Workpiece material: cast iron, HRC52-56

Grinding allowance (single side) : 0.3mm

Roundness requirement: 0.0035

Roughness requirement: cylindrical<Ra0.8

Dresser: single point diamond pen

Dressing parameters: dressing amount 0.02mmx2, cutting speed 80mm/min

.jpg) On-site grinding process tracking and problem summary

On-site grinding process tracking and problem summary

Follow up 4 complete finishing processing, spot check 1st, 3rd, 5th and 7th workpieces;

The roundness of sampling inspection workpiece is not up to standard, which is about 0.007mm;

In a dressing cycle, Ra was significantly reduced from Ra 1.53 to Ra0.83 from the first piece to the last piece.

There are no abnormalities on the surface of the abrasive belt before polishing. After polishing, there are obvious abrasion marks. All the abrasion marks appear in the same position on the workpiece.

.jpg) Problem analysis and solution

Problem analysis and solution

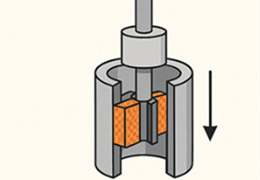

1.Grinding wheel problem:

A. The grinding wheel grit is coarse, and the test workpiece surface is less smooth even there will be scratches.

B. Grinding wheel hardness is soft, abnormal threshing into the grinding area, produce scratches on the surface of the workpiece, affecting the surface roughness;

C. The filter device of the grinding system is not good, which leads to the debris or abrasive D. particles re-entering the grinding area and forming random scratches.

The linear velocity of the grinding wheel is too low

2.Dressing tools problem:

A. The quality of dressing tools (mainly diamond roller or fixed dresser) is poor. Abnormal grain fragmentation or wear in the dressing process can easily form corresponding high and low points on the surface of grinding wheel, resulting in regular scratches on the surface of the workpiece.

B. Dressing parameters:

The overlap ratio is set too low (the guide path is too high, the speed ratio between the roller and the grinding wheel is inappropriate, the dressing amount is too large, etc.)

.jpg)

.jpg)