When it comes to precision hole machining, selecting the right finishing method is critical to achieving desired tolerances, surface finish, and production efficiency. While boring, honing, and grinding all serve to refine internal diameters, each excels in different applications and performance ranges.

In this industry guide, we break down the principles, strengths, and limitations of these three widely used processes, helping manufacturers and engineers make informed decisions for their precision bore applications.

1. Boring – For Efficiency and Versatility

Principle:

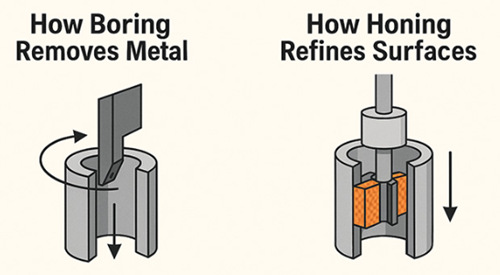

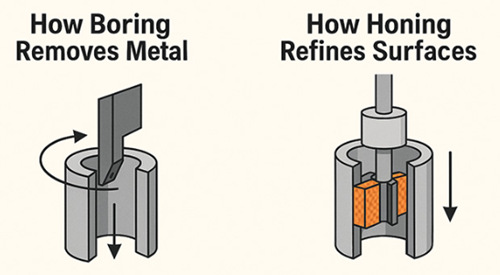

Boring uses a rotating single-point tool to enlarge or finish pre-drilled holes, typically performed on CNC lathes or milling machines.

Key Advantages:

-

Suitable for larger diameters and deeper holes

-

Higher material removal rates than honing or grinding

-

Lower tooling and machine investment

Limitations:

-

Accuracy is influenced by machine rigidity, tool deflection, and vibration

-

Surface finish is generally coarser than honing or grinding

-

Less ideal for tight-tolerance or high-precision fits

Ideal For:

-

Roughing and semi-finishing of bores

-

Non‑critical roundness and straightness requirements

-

Medium‑hardness materials where high productivity is key

2. Honing – For Precision Geometry and Surface Quality

Principle:

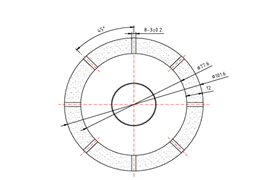

Honing employs a multi‑abrasive stone tool that simultaneously rotates and reciprocates within the bore, removing minute amounts of material through micro‑cutting action.

Key Advantages:

-

Delivers micrometer‑level dimensional accuracy

-

Excellent roundness, cylindricity, and straightness

-

Produces a cross‑hatch surface pattern that improves lubrication retention

-

Reduces residual stresses and enhances bore stability

Limitations:

-

Lower material removal rate – not suitable for heavy stock removal

-

Requires dedicated honing equipment and skilled setup

-

Limited in very large‑diameter applications

Ideal For:

-

Precision bearing housings, hydraulic cylinders, and engine bores

-

Applications requiring close‑fit assembly and long‑term dimensional stability

-

Medium‑to‑high volume production where surface integrity is critical

3. Grinding – For Ultimate Accuracy and Hard Materials

Principle:

Internal grinding uses a rotating abrasive wheel to finish the bore, often performed on dedicated ID grinders or CNC grinding machines.

Key Advantages:

-

Achieves sub‑micron tolerances and exceptional surface finish

-

Capable of machining hardened materials (HRC 60+)

-

Suitable for small‑ to medium‑diameter precision bores

Limitations:

-

Low material removal rate – primarily a finishing process

-

Demanding fixturing and wheel‑dressing requirements

-

Higher per‑part cost compared to boring and honing

Ideal For:

-

Precision instrument components, aerospace bearings, and medical implants

-

Hardened steel, ceramics, and superalloys

-

Applications where surface roughness (Ra < 0.2 µm) is critical

Conclusion: Matching Process to Application

-

Choose Boring when you need to remove significant material quickly, with moderate accuracy requirements.

-

Choose Honing when you require excellent cylindricity, a lubricant‑retaining surface, and micrometer‑level precision in medium‑volume production.

-

Choose Grinding when working with hardened materials, requiring sub‑micron tolerances, or producing high‑value precision components.

Our engineering team specializes in abrasive and finishing solutions for precision hole manufacturing. Whether you’re honing cylinder liners, grinding bearing bores, or selecting the right process for a new component, we can help optimize your production for accuracy, surface quality, and cost‑efficiency.

Contact Us

Email: [email protected]

WhatsApp: +8619900915906