When efficiency and finish quality matter in heavy-duty grinding operations, machine rigidity plays a crucial role. In this case study, we explore how a precision-focused foundry faced vibration issues while using coarse-grit CBN wheels to remove large gating material from cast iron parts—and how our team helped identify the root cause and recommend viable solutions.

Customer Challenge

A high-volume cast iron parts manufacturer needed to quickly and cleanly remove thick gating material after casting. Initial trials with our fine-grit CBN wheels achieved excellent surface quality, but grinding efficiency fell short of production targets. To boost removal rates, the customer switched to a coarser-grit CBN wheel, only to encounter severe chatter marks on the grinding surface, along with reduced overall efficiency.

Problem Analysis

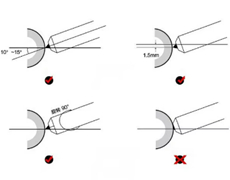

Our team reviewed grinding videos and machine specifications provided by the customer. It became clear that the coarse-grit CBN wheel required higher spindle power and greater machine rigidity to maintain stable cutting forces. However, the customer’s robotic arm setup was relatively slender, leading to vibration under increased grinding load.

This mismatch between wheel aggression and machine stiffness resulted in chatter, poor surface finish, and ironically—slower material removal.

Proposed Solutions of Preventing Chatter in Casting Gate Removal

Increase Machine Rigidity – Strengthen or replace the robotic arm to withstand higher grinding forces.

Optimize Wheel Specification – Use a medium-grit CBN wheel that balances cutting speed and force requirements, avoiding extremes in grit size.

Process Adjustment – Reduce depth of cut and optimize feed rates to lower dynamic loads on the machine structure.

The customer opted to pursue machine reinforcement while keeping the coarse-grit wheel, acknowledging that long-term efficiency gains depend on equipment stability.

Why CBN Wheels Are Ideal for Casting Applications

-

High Wear Resistance – Maintains form and sharpness during prolonged heavy grinding.

-

Thermal Stability – Reduces risk of workpiece burn, especially on cast iron.

-

Adaptable Grit Options – Available in various grit sizes to match machine capability and finish requirements.

Lessons Learned

This case underscores the importance of machine‑wheel compatibility. Even the most advanced abrasive tools cannot perform optimally if the machine lacks the rigidity to support the required cutting forces. A collaborative approach between tooling specialists and production engineers is key to unlocking full grinding potential.

Need Support with Your Grinding Setup?

Whether you're removing gates, cleaning welds, or finishing hardened components, our technical team can help you select the right wheel and optimize your process. Contact us for a grinding audit or a custom wheel recommendation.

About Us

We specialize in engineered abrasive solutions for demanding industrial applications. From CBN and diamond wheels to complete grinding process support, we help manufacturers achieve higher productivity, better surface quality, and longer tool life—even on challenging materials like cast iron, superalloys, and composites.