Diamond pellets are mainly used for grinding optical glass, and also for finish grinding of lens, ceramics, crystal and other optical elements.

Metal bond diamond finish pellets

Metal bond diamond finish pellets

Metal bond diamond pellets are used in the finish grinding process of optical glass elements. The main function of diamond pellets is to remove the damaged layer and rough surface left by the milling process, to ensure that the optical glass elements have a certain surface size and machining margin.

Resin bond diamond super finish pellets

Resin bond pellets are used in super finish grinding process of optical glass elements, which remove the damaged layer (rough surface) left over from the previous finish grinding process, and further improve the shapes and sizes of optical elements, smoothness and aperture value. Also,the appearance is similar to the metal bond diamond pellet.

Generally for optical glass ,first step is using metal diamond pellets, then using resin diamond pellets. However, for soft glass or processes with high finish requirements, resin pellets may be used. The surface finish of resin pellets is better.

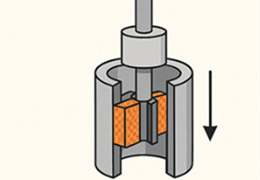

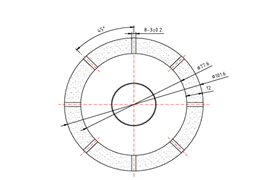

Available Shapes and Structure:

Round, triangles, squares, hexagons, etc. Diamond finish and super finish columns are divided into flat, flat concave, flat convex, double concave, double convex and so on. In order to chips removal, the end face processing has two slots, four slots, six slots and eight slots.

Standard size of Pellets

Standard size of Pellets

| Diameter(mm) |

Thickness(mm) |

| 2 |

2, 4 |

| 2.5 |

1.5 |

| 3 |

2 |

| 4 |

2, 3, 5, 12 |

| 5 |

6 |

| 6 |

2, 3, 4, 12 |

| 7 |

12 |

| 8 |

2, 3, 4, 5, 12 |

| 10 |

2, 3, 4, 5, 12, 15 |

| 11 |

21 |

| 12 |

3, 5, 7, 12, 15, 20 |

| 13 |

12 |

| 14 |

4, 5, 7, 15 |

| 15.5 |

10 |

| 16 |

5, 7, 10, 18, 20 |

| 17 |

20 |

| 18 |

24 |

| 20 |

10, 24 |

| 21 |

5, 15, 20 |

| 23 |

10, 18 |

| 25 |

15, 30 |

| 25.5 |

20 |

| 26 |

10, 16 |

| 30 |

10, 18 |

| 31 |

12.5 |

| 32 |

6, 18, 20 |

| 38 |

29 |

| 40 |

20 |

| 54 |

31 |

| 56 |

28 |

Available Grits: 600#、800#、1000#、1500#、1800#、2000#, etc.

Advantages of Diamond Pellets

1.Excellent cutting performance, endurance and high heat delivery

2.Homogeneous scratch-free surfaces

3.Optically measurable after grinding

4.Reduced polishing times

5.Improved surface finishes

6.High dimensional accuracy

7.High process repeatability

8.Low sub surface damage