What is a rotary dresser?

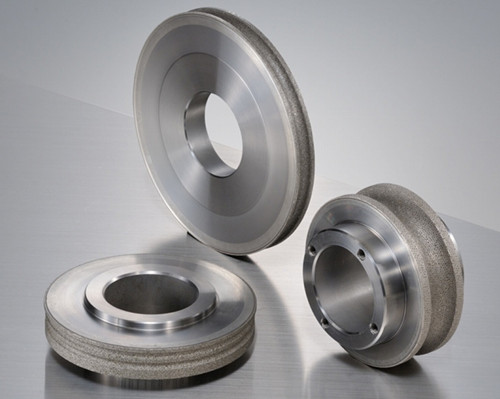

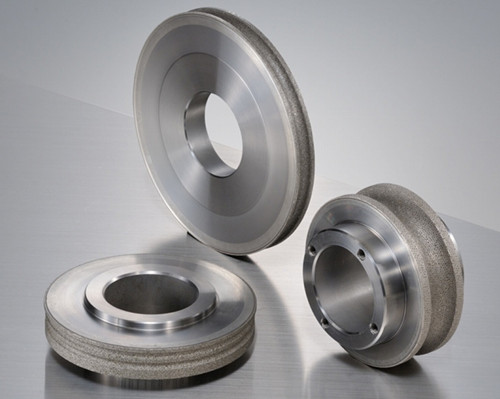

The so-called diamond roller is a high-efficiency, high life and low-cost grinding wheel dressing tool that uses electroplating or powder metallurgy to set a large number of diamond particles on the surface of a steel roller, which is used for high-volume molded grinding on special machine tools and gear grinding machines.

Rotating at a certain speed (to reduce the relative speed of the wheel and the grinding wheel), the surface of the grinding wheel rotates at high speed to produce grinding and rolling action, so that the grinding wheel to obtain and the wheel profile match the sharp working surface.

Among them, the common HNT diamond roller can effectively replace the single crystal diamond pen to dress the grinding wheel, and its production efficiency is greatly improved, and the surface quality and precision of the processed parts are higher.

The working principle of the diamond roller is: by installing on the dressing device of the grinding machine, the diamond roller dresses the ordinary ceramic grinding wheel or CBN grinding wheel, and the grinding wheel is shaped and then grinds the parts, so that the profile and precision and size of the diamond roller are copied to the surface of the processed parts through the grinding wheel. It is characterized by simple operation of the machine tool, low technical requirements for operators, good consistency of precision and stable quality of the processed products, which can significantly improve productivity and product quality, reduce manufacturing costs, and easily realize the automation of grinding process. Compared with the traditional single-point diamond pen dressing, the production efficiency is greatly improved, and the surface quality and precision of the processed parts are higher, especially suitable for high-precision, high-volume production.

What is the difference between wheel dressing and wheel truing?

Wheel dressing and wheel truing are both processes used in maintaining grinding wheels, typically used in machining or sharpening applications. While they serve similar purposes, they are distinct processes with different objectives:

-

Wheel Dressing:

- Purpose: Wheel dressing is primarily done to restore the cutting efficiency and accuracy of the grinding wheel. Over time, the abrasive grains on the surface of the wheel can become dull or clogged with material from the workpiece. Dressing removes these dull grains and exposes fresh abrasive particles, restoring the wheel's cutting ability.

- Process: Wheel dressing involves removing a small amount of material from the surface of the grinding wheel using a dressing tool. This may involve cutting or abrasion processes to reshape the wheel and expose fresh abrasive grains. Dressing can be done manually with handheld tools or automatically with specialized machinery.

-

Wheel Truing:

- Purpose: Wheel truing is focused on restoring the geometric shape and concentricity of the grinding wheel. Over time, grinding wheels can become misshapen due to wear, uneven loading, or improper mounting. Truing ensures that the wheel runs true, meaning it rotates smoothly and evenly without wobbling.

- Process: Wheel truing involves removing material from the circumference of the grinding wheel to reshape it into a perfect circle. This process is usually performed with a truing tool or a diamond dresser mounted on a truing device. By adjusting the position of the truing tool relative to the rotating wheel, material is gradually removed to achieve the desired shape.

In summary, wheel dressing focuses on restoring the cutting ability of the grinding wheel by removing dull abrasive grains, while wheel truing aims to restore the geometric shape and concentricity of the wheel for smooth and accurate grinding operations. Both processes are essential for maintaining the performance and longevity of grinding wheels.

Moresuperhard Diamond & CBN Wheel Dressing Machine

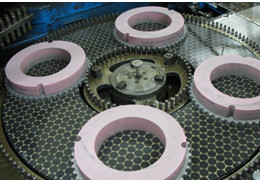

The Wheel Dresser is designed to provide easy and efficient dressing of diamond /CBN grinding wheels and grinding wheel spindles consisting of several grinding wheels.

►Diamond & CBN wheel dressing machine Models

NM-X3

NM-X5

NM-X6

The NM-X3 can be used for dressing theshape of the wheel being dressed by usingthe principle of the difference in rotationalspeed between the wheel to be dressedand the dressing wheel.

The NM-X3 is capable of dressing diamondwheels, CBN wheels, and multiple wheelsin a simple and highly efficient manner,and can dress flat, angular, circular, andmolded wheels.The machine is easy to operate and highly accurate.

MSH-X5 InformationMSH-X5 uses the principle of the dif-ference in rotation speed between thegrinding wheel to be dressed and thedressing grinding wheel to realize theshape dressing of the grinding wheelto be dressed.The machine itself can provide simpleand efficient dressing of diamondgrinding wheels, CBN grinding wheelsand grinding wheel sets composed ofmultiple grinding wheels. it can dressflat, angle, arc and shaped grindingwheels. This machine is easy to oper-ate and highly accurate.

Dressing tips:

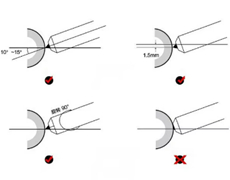

1. Diamond roller dressing grinding wheel. Under normal circumstances, the linear speed of the grinding wheel is 5-10m/s faster than the roller.

2. When the roller and the grinding wheel rotate in the same direction for dressing, the surface of the grinding wheel will be rougher, the grinding wheel will be sharp, and the margin will be reduced quickly, but the surface quality of the workpiece will become worse.

When the roller and grinding wheel rotate in opposite directions for dressing, the surface of the grinding wheel will be smoother, the grinding wheel will be flat, suitable for fine grinding, and the surface quality of the workpiece will become better.

3. The greater the linear speed difference between the diamond roller and the grinding wheel, the smoother the surface of the grinding wheel. (However, there are peaks, and bigger is not necessarily better. It needs to be adjusted according to the on-site conditions)

4. The reverse rotation limit is 0 linear speed difference and synchronous extrusion.

Application of Diamond Roller:

At present, HNT diamond rollers are mainly used in the following industries, especially in the automobile, machine tools, measuring tools and other industries are widely used.

1. Automobile parts industry: crankshaft, valve body, piston ring, oil needle, oil needle body, ball cage universal joints, oil nozzle oil pump and so on.

2. Gear industry: double-piece single-bevel, single-piece double-bevel, gear tooth top, full tooth, etc..

3. Machine tool industry: guide rail, slide, ball screws, etc.

4. Bearing industry: ball bearing grooves, linear track vice, taper bearings, column bearing grooves, textile bearings and so on.

5. Measurement and cutting tools industry: calipers, drills, saw blades, milling cutter slots and blades, taps and threads, etc.

6. Light industry: refrigerator compressor, bicycle center shaft, etc.

7. Hydraulic industry: piston pump connecting rod, etc.

8. Aerospace industry: turbine blades, blade tooth roots, etc.