What should we need to consider when choosing diamond grinding wheels?

When choosing diamond grinding wheels, we often encounter such problems like:

1. What kind of abrasive wheel is good? Diamond or CBN?

2. What kind of bonding material is suitable for the grinding wheel: electroplated, resin, vitirfied, or metal?

.jpg)

3. What kind of grinding wheel is sharper?

4. What kind of grinding wheel has a longer service life?

5. Does the diamond grinding wheel need to be dressed? How to dress it?

…..

These problems often make us at a loss when choosing a grinding wheel. Because we don't know what each option means, let alone the difference between each option. Under such circumstances, we can only "cross the river by feeling the stones", exploring the unknown. However, such blind exploration costs the company a huge price, ranging from sample fees again and again to delays or even abandonment of projects.

So, when we understand what we really choose when choosing a superhard grinding wheel. We can be targeted and make wise choices.

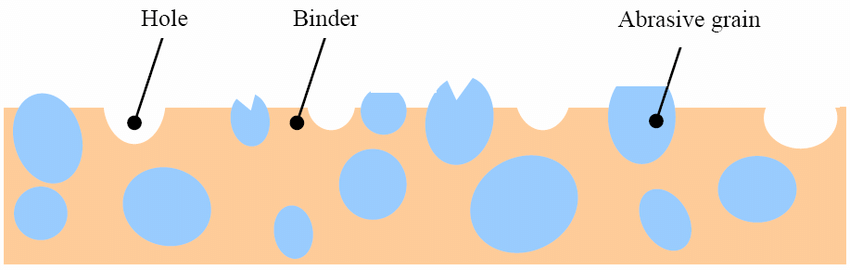

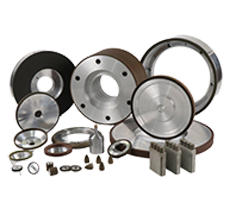

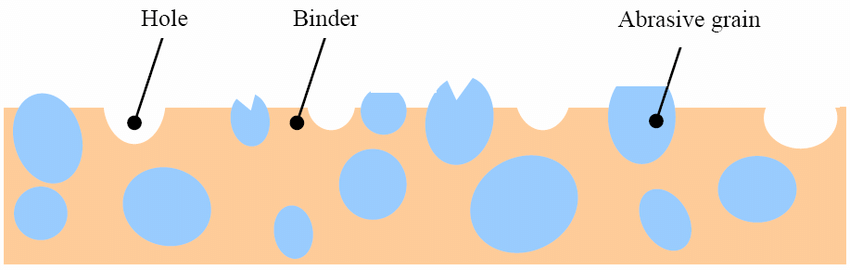

First of all, we have to be clear that the three elements of a grinding wheel are

abrasives, binders and holes. These three elements are integral parts of a superhard grinding wheel. At the same time, these three elements also closely affect the performance of the grinding wheel. A small change in each element will bring about a great change to the grinding wheel.

So how exactly do

abrasives, binders and holes affect wheel performance?

Today we will start with abrasives, and then analyze each element one by one.

When we are choosing superhard grinding wheels, we are choosing abrasives.

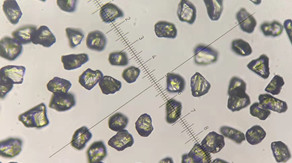

As we all know, superabrasives are divided into diamond abrasives and cubic boron nitride abrasives (

CBN).

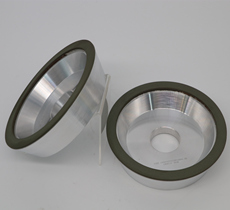

Diamond abrasives are known to the world for their unique hardness. Unparalleled hardness, unparalleled wear resistance is synonymous with diamond. However, the indestructible diamond will also show its fragile side when it encounters iron group metals or high temperature (about 700 ℃).

The hardness of cubic boron nitride (CBN) is second only to diamond, and it has excellent thermal and chemical stability while having high hardness. These two characteristics are the biggest difference between it and diamond.

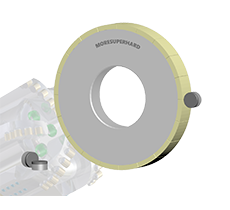

With a global development strategy and comprehensive multilingual business departments, Moresuperhard keeps an eye on the latest developments in the global grinding industry and is committed to providing high-quality and efficient grinding products and services to our customers worldwide! We also accept customized orders to suit your needs.

If you have any questions about

choosing diamond grinding wheels, please feel free to contact us! You can leave us your questions below, and we will contact you as soon as possible!

---EDITOR: Owen Ma,Jackie Wang

---POST: Jackie Wang

.jpg)