What is a resin CBN grinding wheel?

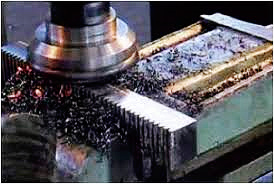

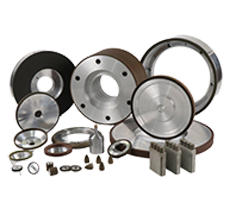

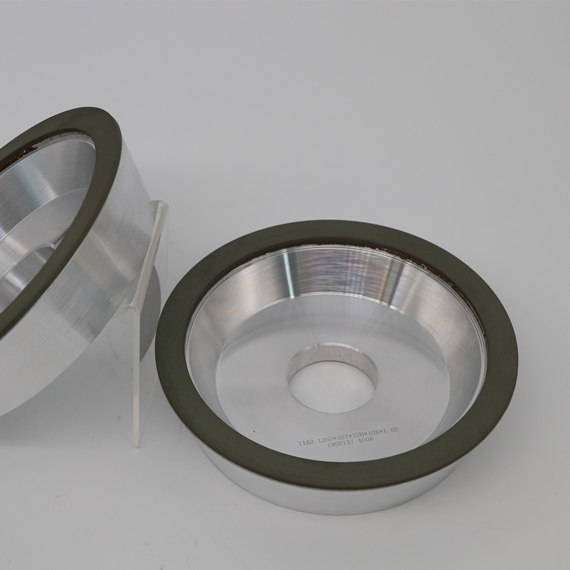

A resin CBN wheel is a grinding tool with a certain degree of rigidity (strength and hardness) by cementing a CBN grain together with an organic polymer compound as a binding agent. Resin CBN grinding wheels can process various metal and non-metal materials, especially in the field of fine grinding and polishing processing with superior processing characteristics.

Resin bonded CBN grinding wheels are widely used in rough processing, fine and polish grinding processes, and the resin bonded CBN grinding wheels have

the following characteristics.

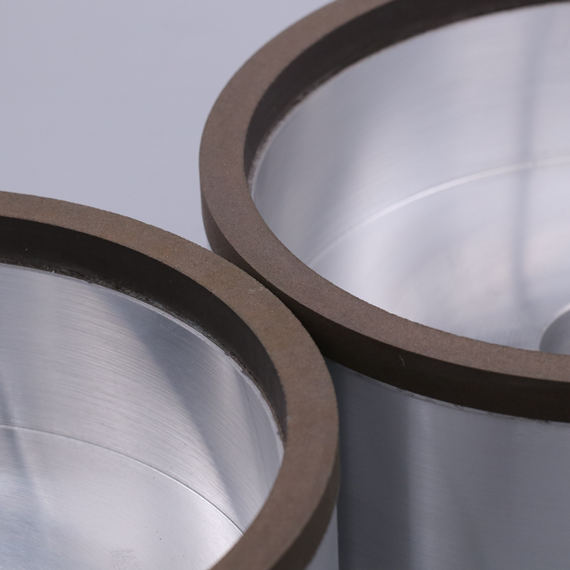

(1) High bonding strength. Compared with ceramic bond, resin bonded CBN grinding wheels have high bond strength, and the grinding line speed of resin grinding wheels reaches 80~120m/s, and can withstand large grinding pressure.

(2) It has a certain degree of elasticity. Compared with ceramic bonded CBN grinding wheels, resin bonded grinding wheels have good toughness, a certain degree of plasticity and ductility, and are suitable for preparing various specifications of flake grinding wheels and high-speed cutting grinding wheels. Due to a certain elastic deformation, it can buffer the effect of grinding force and thus has good grinding effect, polishing effect and can improve the roughness of the processed surface.

(3) It can be made into abrasives with various complex shapes and special requirements. Due to the low hardening temperature of resin bonded CBN grinding wheels, they can be hardened at room temperature and have a small shrinkage rate, so they can be made into grinding wheels of various complex shapes and special requirements.

(4) It helps to prevent burns on the workpiece being ground. The heat generated by the workpiece in the grinding process causes the resin to carbonize, prompting the blunted abrasive to fall off automatically, revealing new sharp abrasive grains, reducing the heat in the grinding area and avoiding workpiece burns.

(5) Low hardening temperature. Resin CBN grinding wheels have low hardening temperature, short production cycle, simple equipment, and are conducive to specialized production.

What are the applications of resin CBN grinding wheels?

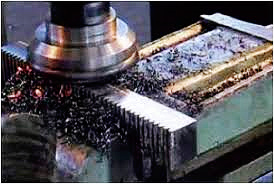

Resin CBN grinding wheels are suitable for grinding workpieces such as hardened steel, high-speed steel, cast iron, stainless steel and nitrided stainless steel. At the same time, in order to improve production efficiency, people began to use CBN grinding wheels on low-speed grinding machines to increasingly replace ordinary grinding tools. At present, resin CBN grinding wheels are widely used for precision grinding of workpieces containing iron group elements in industries or fields such as automotive, bearings, compressors and precision molds, and have become an irreplaceable tool in manufacturing production and grinding processing.

What should we know when using resin CBN grinding wheels?

What should we know when using resin CBN grinding wheels?

However, compared with other bonded grinding wheels, the shortcomings of resin bonded CBN wheels are: poor alkali and water resistance, easy aging; lower heat resistance, greater wear when grinding and processing, unsuitable for shaped grinding; low porosity, processing with odor, easy to cause environmental pollution problems. Cubic boron nitride is not suitable for grinding carbide and non-metallic hard materials. Under high grinding temperature, CBN will chemically react with alkaline aqueous solution. CBN grinding wheels will decompose in alkaline solution at 300℃ and can decompose in boiling water in trace amount, as a result, the abrasive grain crystal shape will be destroyed, so when grinding, only oil-based coolant can be used instead of water-based coolant.

.jpg)