With the continuous development of industrial automation, intelligence and flexibility, robotics is widely used in the field of automotive parts manufacturing and processing, such as engine block, cylinder head, wheel hubs, luggage racks, interior trim, battery cover bottom bracket and so on.

.jpg)

Since the performance and safety of automobiles mostly depend on the design and manufacture of the parts, higher requirements have been put forward for the precision of robot processing, and uniform surface roughness and precise dimensional specifications have become important indicators of high-quality automotive parts.

Moresuperhard's high-speed electric spindle is based on the characteristics of high speed, high precision, high torque, high power and small size, and combined with the advantages of robot technology, it greatly reduces the cost of machining equipment, improves machining flexibility, and brings high-efficiency, high-quality, and low-cost solutions for automotive parts machining.

Application Case of Automotive Parts Processing:

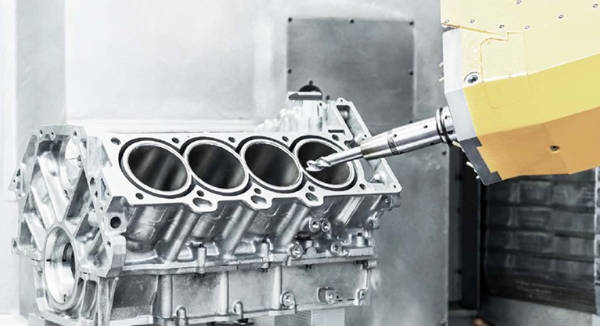

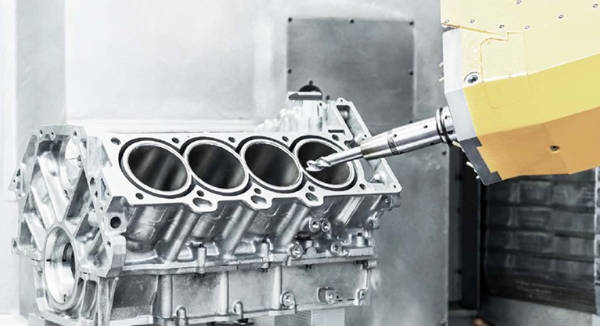

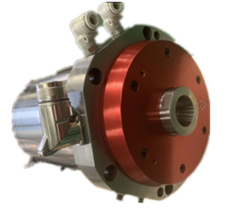

1. Aluminum engine block floating deburring

Configuration: Robot + Floating Spindle

Application: Deburring

Material: Aluminum engine block

Advantage: With radial + axial floating flexible system, suitable for flexible installation in a variety of robots, the contact pressure with the workpiece can be pneumatically adjusted, 360 ° to maintain consistent pressure. Maximum spindle speed of 60,000 rpm, maximum torque of 27Ncm, maximum power of 850W, supporting ER11 collet, can be applied to ABB, Kuka, Stäubli and other industrial robot assembly for a variety of metal stainless steel, cast iron, aluminum alloy, non-metallic materials SMC, ABS, carbon fiber, flexible floating deburring precision machining.

| Technical Parameters |

| Motor type |

Three-phase synchronous high-speed motor |

| Speed range |

6000-60000rpm |

| Torque Maximum |

27Ncm |

| Power Maximum |

850W |

| Weight |

1.0kg |

| Bearing |

2 x ceramic ball bearings, grease lubricated |

| Protection class |

IP55 |

| Taper runout |

≤1µm |

| Tool clamping range |

φ1.0-8.0mm |

| Tool change mode |

Manual tool change |

| Cooling method |

Sealed air cooling |

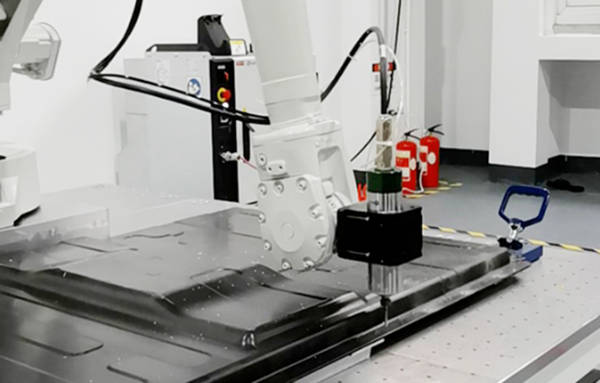

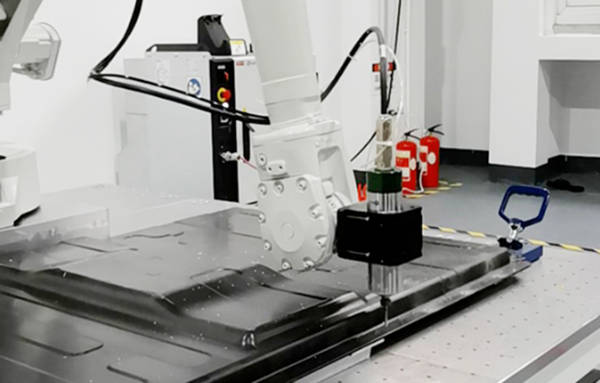

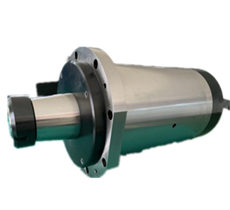

2. New energy vehicle lithium battery cover drilling

Configuration: Robot + High-speed spindle

Application: Drilling

Material: SMC composite material

Advantage: The spindle adopts ceramic bearings, maximum speed of 50,000rpm, maximum power of 2KW, maximum torque of 2.15Nm, chuck clamping range of 0.5-8.0mm, standard IP57 and IP67 underwater work safety protection level, widely used in the field of automotive non-metallic SMC, ABS material cutting, drilling, and metal stainless steel, cast iron, aluminum alloy, such as milling, grinding, Chamfering and deburring, etc. It has excellent performance in the drilling processing of SMC lithium battery cover plate of new energy automobile parts.

| Technical Parameters |

| Motor type |

Three-phase synchronous high-speed motor |

| Speed range |

3000-50000rpm |

| Torque Maximum |

21527Ncm |

| Power Maximum |

2000W |

| Weight |

3.5kg |

| Bearing |

3 x ceramic ball bearing, grease lubrication |

| Protection class |

IP57/67 |

| Taper runout |

≤1µm |

| Tool clamping range |

φ0.5-8.0mm |

| Tool change mode |

Manual tool change |

| Cooling method |

External fixture cooling |

.jpg)

.jpg)