Introduction to Tool Grinding Motorized Spindle

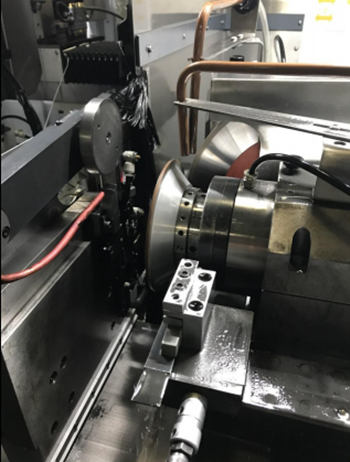

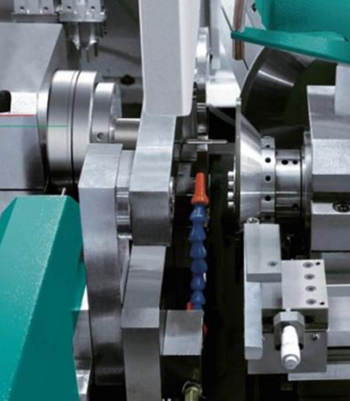

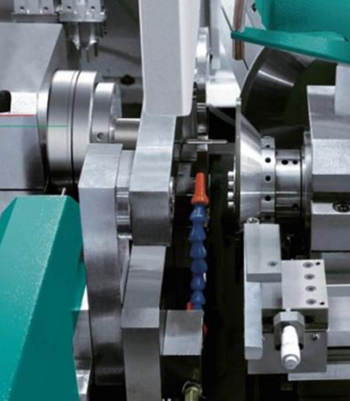

Tool grinding Motorized spindles are mainly used in automatic CNC tool grinding machines, which can rotate in both directions and grind in multiple directions, and are used for processing various sizes of tools such as drills, milling cutters, taps, turning inserts, etc. Tool grooving and sharpening is completed in one clamping process; this series of Motorized spindles can not only withstand large radial force, but also a certain amount of axial tension and thrust, and has the characteristics of high precision and high rigidity.

With the development of tool grinding Motorized spindle, the motor gradually adopts copper rotor or permanent magnet synchronous motor, the motor efficiency and energy saving are improved simultaneously, and the pressure air sealing technology is adopted to improve the air sealing structure, which ensures the reliability of spindle operation and long life of 24-hour continuous operation.

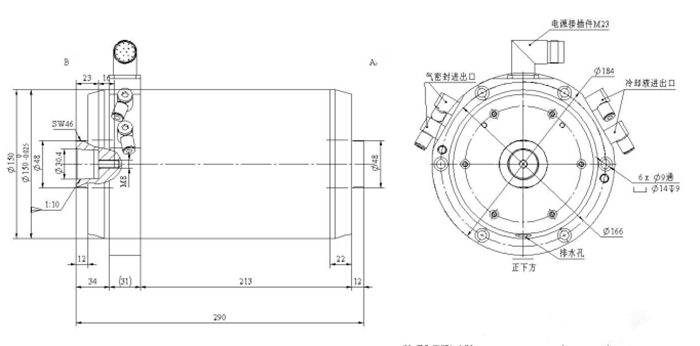

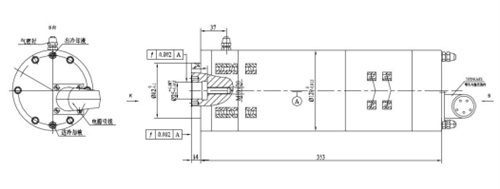

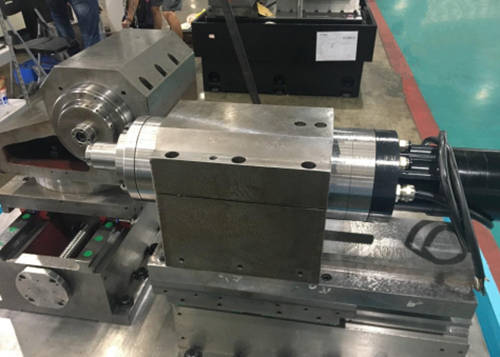

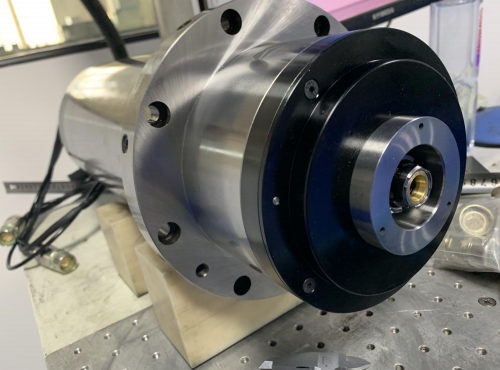

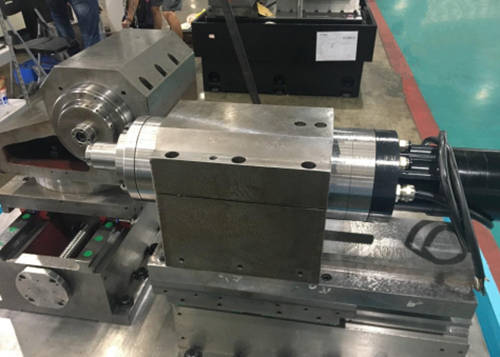

Double Head Grinding Spindle:

Double Head Grinding Spindle Product performance indicators

Double Head Grinding Spindle Product performance indicators

Installation size: φ150×290, φ180×293, φ150×322, etc.

Toolholder interface: HSK-F50 standard taper hole

Accuracy: Internal hole and end runout ≯ 0.002mm at both ends; runout ≯ 0.005mm after installation

Runout after shank installation ≯ 0.005mm

Vibration: ≯ 0.4mm/s (RMS) in the full speed range

Rated power: *7.5kW (S1)

Rated speed: 6000r/min

Rated torque: 12Nm

Rated voltage: 380V

Motor type: Permanent magnet synchronous motor

Lubrication method: grease lubrication

Sealing method: gas seal + mechanical seal

Bearing brand: NSK

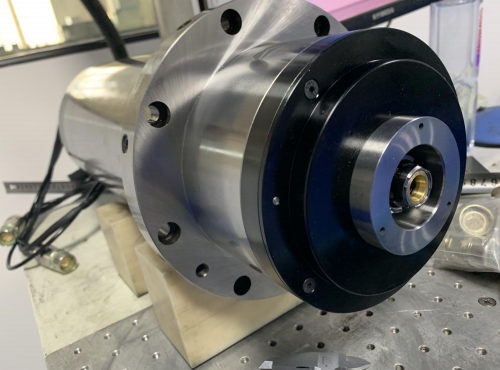

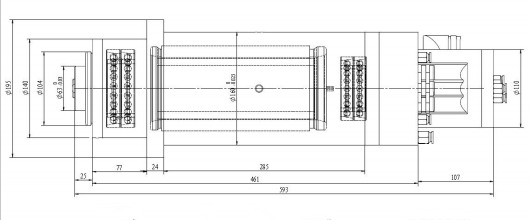

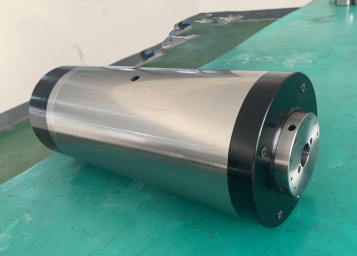

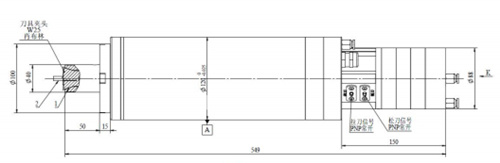

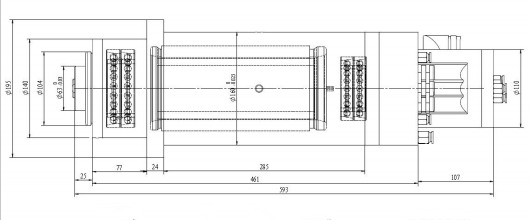

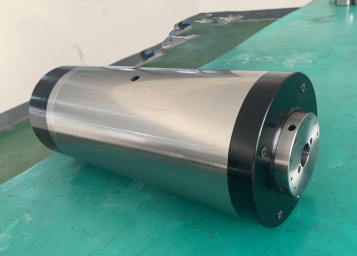

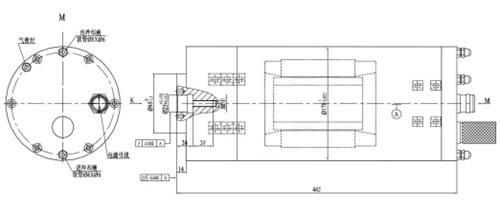

Automatic Grinding Wheel Replacement Grinding Spindle:

Automatic wheel replacement grinding spindle performance indicators:

Automatic wheel replacement grinding spindle performance indicators:

Installation size: φ160×593

Toolholder interface: HSK-E50 (automatic tool change, hydraulic)

Tool pulling force: 11±5%kN

Accuracy: ≯ 0.002mm for bore and end runout, ≯ 0.008mm for runout after shank installation

Vibration: ≯ 1mm/s in the full speed range (RMS)

Rated power: 25kW (S1)

Rated speed: 6000r/min (maximum speed 12000r/min)

Rated torque: 40Nm

Rated voltage: 380V

Motor type: permanent magnet synchronous motor

Lubrication method: grease lubrication

Sealing method: gas seal + mechanical seal

Bearing brand: NSK

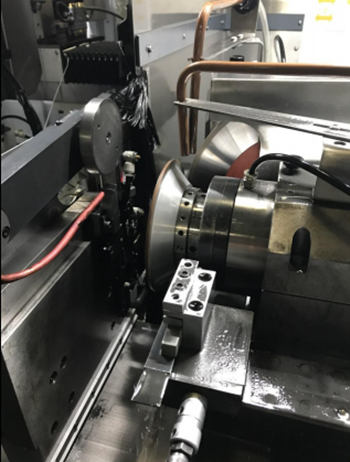

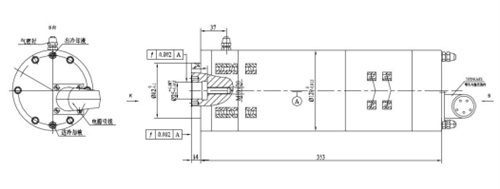

High-frequency Peel Grinding Spindle:

Motorized Spindle performance indicators:

Installation size: φ120×353

Toolholder interface: D25

Accuracy: Inner hole and end runout ≯ 0.002mm, runout after installation of toolholder ≯ 0.005mm.

Runout after shank installation ≯ 0.005mm

Vibration: ≯ 0.6mm/s at full speed (RMS)

Rated power: 3.4kW (S1)

Rated speed: 12000r/min

Rated torque: 2.7Nm

Rated voltage: 350V

Motor type: Three-phase asynchronous motor

Lubrication method: grease lubrication

Sealing method: gas seal + mechanical seal

Bearing brand: NSK

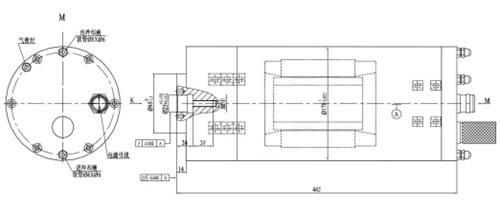

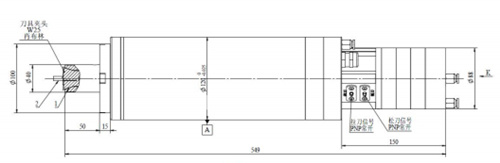

Motorized Spindle performance indicators:

Installation size: φ170×445

Toolholder interface: D25

Accuracy: Runout of bore and end face ≯ 0.002mm, runout of tool shank after installation ≯ 0.005mm.

Runout after shank installation ≯ 0.005mm

Vibration: ≯ 0.6mm/s at full speed (RMS)

Rated power: 12.5kW (S1)

Rated speed: 9000r/min

Rated torque: 13.2Nm

Rated voltage: 350V

Motor type: Three-phase asynchronous motor

Lubrication method: grease lubrication

Sealing method: gas seal + mechanical seal

Bearing brand: NSK

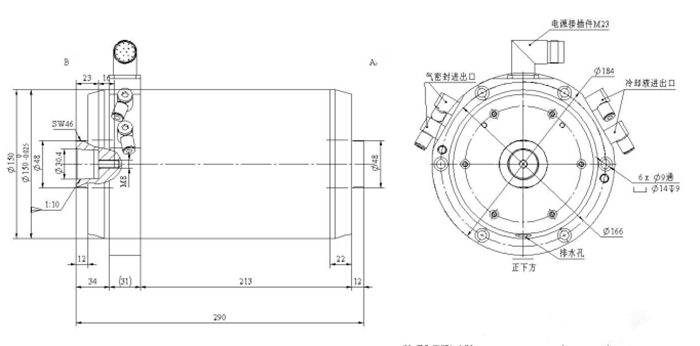

Motorized Spindle performance indicators:

Installation size: φ120×549

Toolholder interface:

Schaublin w25 collets (pneumatic, automatic tool change)

Accuracy: Runout of bore and end face ≯ 0.002mm, runout of tool shank after installation ≯ 0.002mm.

Runout after shank installation ≯ 0.002mm

Vibration: ≯ 0.6mm/s in the full speed range (RMS)

Rated power: 1.8kW (S1)

Rated speed: 3000r/min

Rated torque: 5.7Nm

Rated voltage: 380V

Motor type: Three-phase asynchronous motor

Lubrication method: grease lubrication

Sealing method: gas seal + mechanical seal

Bearing brand: NSK

.jpg)