Centerless grinding: the center hole of the workpiece does not need to be centered during the grinding process.

.jpg)

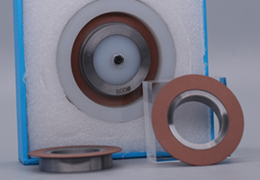

Centerless grinding process requires two wheels:

1. Centerless grinding wheel: to grind the workpiece, choose super-hard grinding wheel, general grinding wheel, according to the processing of different materials to choose the appropriate grain size and binding agent

2. Rubber guide wheel: the guide theory by driving the cylindrical workpiece in the pad to rotate, play a role in guiding and positioning, contact with the workpiece to bring the workpiece to the appropriate grinding area, while controlling the rotary movement of the workpiece, so that the workpiece in the right position, get the right grinding, absorb the vibration and impact generated in the grinding process, improve the precision and efficiency of grinding.

Processing object: cylindrical workpiece

Advantages of Centerless grinding:

1. High precision: because the workpiece does not need center hole positioning in the grinding process, there is no center hole deviation, which affects the grinding precision.

2. Good surface quality: less grinding traces on the surface of the workpiece during machining.

3. High productivity: multiple workpieces can be ground at the same time, which greatly improves productivity.

4. Energy saving: no center hole positioning is required during the machining process, so unnecessary operations can be reduced during the machining process.

Customer Request of Centerless Grinding:

Steel, alloy steel (type 12Х18Н10Т), nickel-based alloys (type Inconel 718) with a maximum diameter of Ф60 mm.

The length of the processed bars is up to 12 m.

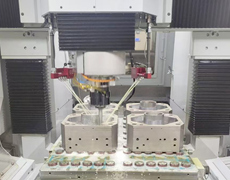

The machine must be equipped with two grinding wheels, as well as a roller conveyor for feeding and receiving the bars.

.jpg)